Ellipsoidal reflector perifocus high-precision positioning device and method

A technology of ellipsoidal reflector and positioning method, which is applied in the field of high-precision positioning devices near the focus of ellipsoidal reflector, which can solve the problems of large coma, astigmatism, and extremely high accuracy of assembly and adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

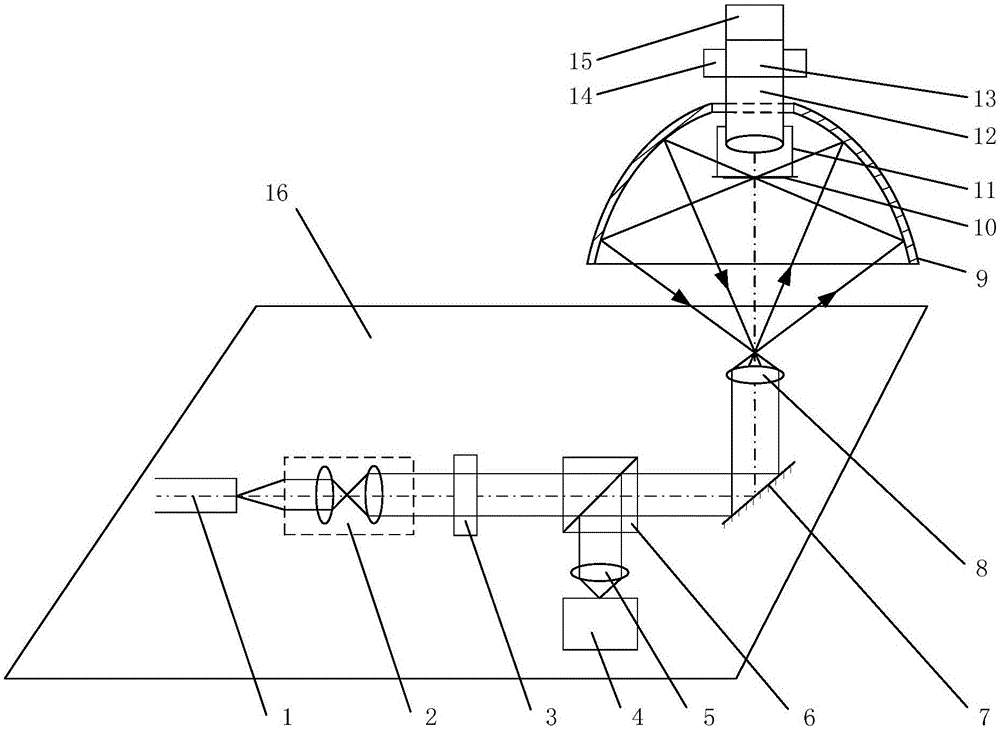

[0036] This embodiment is an embodiment of an ellipsoid reflector near-focus high-precision positioning device.

[0037] The high-precision positioning device near the focus of the ellipsoid mirror in this embodiment has a schematic structural diagram as figure 1 shown. The near-focus high-precision positioning device of the ellipsoid mirror includes a laser 1, a collimator beam expander 2, an attenuation plate 3, a far-focus CCD 4, a tube mirror 5, a beam splitter 6, a plane mirror 7, a far-focus focusing objective lens 8, an ellipsoid Spherical reflector 9, coating sample 10, connection table 11, near-focus focusing objective lens 12, piezoelectric ceramics 13, X-Y axis precision drive table 14, near-focus CCD15 and six-degree-of-freedom workbench 16;

[0038] Laser 1, collimator beam expander 2, attenuation plate 3, far-focus CCD 4, tube mirror 5, beam splitter 6, plane mirror 7 and far-focus focusing objective lens 8 form the lower optical path, which is set on the six-de...

specific Embodiment 2

[0041] This embodiment is an embodiment of a high-precision positioning method for the near focus of an ellipsoid mirror.

[0042] The high-precision positioning method for the near-focus of the ellipsoidal reflector in this embodiment is implemented on the high-precision positioning device for the near-focus of the ellipsoidal reflector described in Embodiment 1. The method includes the following steps:

[0043] Step a, performing the far focus positioning of the ellipsoidal reflector;

[0044] Step b. On the basis of step a, perform near-focus positioning of the ellipsoidal reflector.

specific Embodiment 3

[0046] This embodiment is an embodiment of a high-precision positioning method for the near focus of an ellipsoid mirror.

[0047] The high-precision positioning method of the near focus of the ellipsoid mirror of the present embodiment, on the basis of the specific embodiment 2, further defines that step a includes the following steps:

[0048] Step a1, turn on the laser 1, and use the attenuation sheet 3 to attenuate the intensity of the parallel light beam emitted from the collimator beam expander 2, so that the image sensor 4 can effectively image;

[0049] Step a2, constantly adjusting the six-degree-of-freedom workbench 10 to obtain the intensity information and roundness information of the light spot collected by the image sensor 4 under different degrees of freedom;

[0050] Step a3, combining the intensity information and roundness information of the light spot into an evaluation function, and establishing a degree of freedom-evaluation function table;

[0051] Step a4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com