A kind of preparation method of the permanent magnet material of low heavy rare earth, high coercive force

A technology of permanent magnet materials and high coercivity, which is applied in the fields of magnetic materials, inductor/transformer/magnet manufacturing, magnetic objects, etc., and can solve the problems of high cost, uneven distribution of heavy rare earth elements in magnets, and difficulty in uniform distribution of heavy rare earth elements, etc. problem, to achieve the effect of less heavy rare earth and improve the coercive force of the magnet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of preparation method of the permanent magnet material of low heavy rare earth, high coercive force of the present invention, it comprises the following steps:

[0027] (1) Mix the rare earth-iron-boron alloy powder with the heavy rare earth metal or alloy powder, heat-treat at a temperature of 500-800°C for 1-20 hours, and keep stirring, so that the heavy rare-earth metal atoms diffuse into the rare earth-iron-boron the surface layer of the alloy powder to obtain a mixture; wherein the mass content of the rare earth-iron-boron alloy powder is 95% to 99.5%, and the balance is heavy rare earth metal or alloy powder;

[0028] (2) Place the mixture in a magnetic field above 1.5T to form a green compact through orientation pressing;

[0029] (3) The compact is prepared into a sintered rare earth-iron-boron permanent magnet material through high-temperature sintering and tempering treatment.

[0030] In a further scheme, the main component of the rare earth-iron-boro...

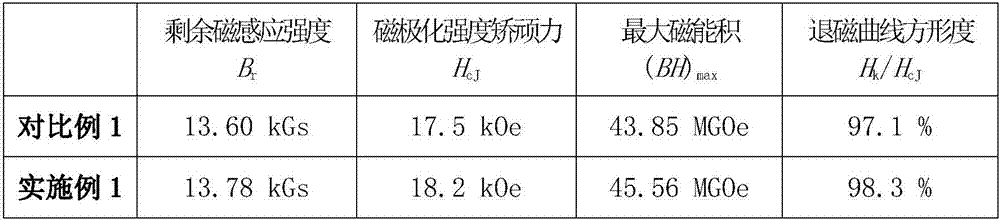

Embodiment 1

[0034] (1) Nd with an average particle size of 3.0 μm 31 Fe 68 B powder with DyF with an average particle size of 3.0 μm 3 After the powder is mixed according to the ratio of 98:2, it is heat-treated at 600°C for 10 hours with constant stirring, so that the heavy rare earth metal atoms diffuse into the surface layer of the rare earth-iron-boron alloy powder to obtain a mixture;

[0035] (2) Place the mixture in a 1.6T magnetic field to make a green compact through orientation pressing;

[0036] (3) The compact is prepared into a sintered rare earth-iron-boron permanent magnet material through high-temperature sintering and tempering treatment.

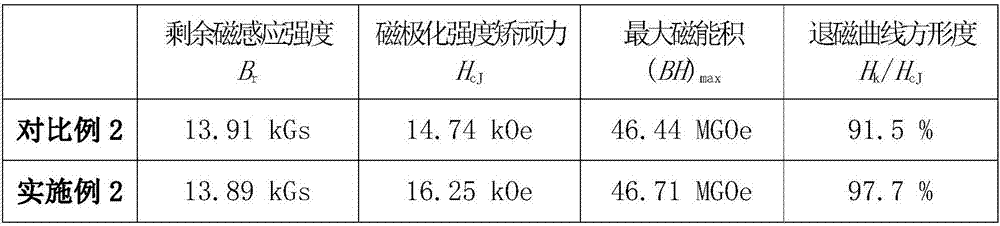

Embodiment 2

[0044] (1) Nd with an average particle size of 2.6 μm 31 Fe 68 B powder with DyH with an average particle size of 3.0 μm 3 After mixing the powders at a ratio of 99:1, heat treatment at 580°C for 15 hours with constant stirring, so that the heavy rare earth metal atoms diffuse into the surface layer of the rare earth-iron-boron alloy powder to obtain a mixture;

[0045] (2) Place the mixture in a 2.0T magnetic field to make a green compact through orientation pressing;

[0046] (3) The compact is prepared into a sintered rare earth-iron-boron permanent magnet material through high-temperature sintering and tempering treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com