Silicon wafer surface passivation technique

A silicon wafer surface and silicon wafer technology, applied in the field of photovoltaic solar cells, can solve the problems of high cost, complicated operation, poor passivation effect, etc., and achieve the effects of easy operation, simple process and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

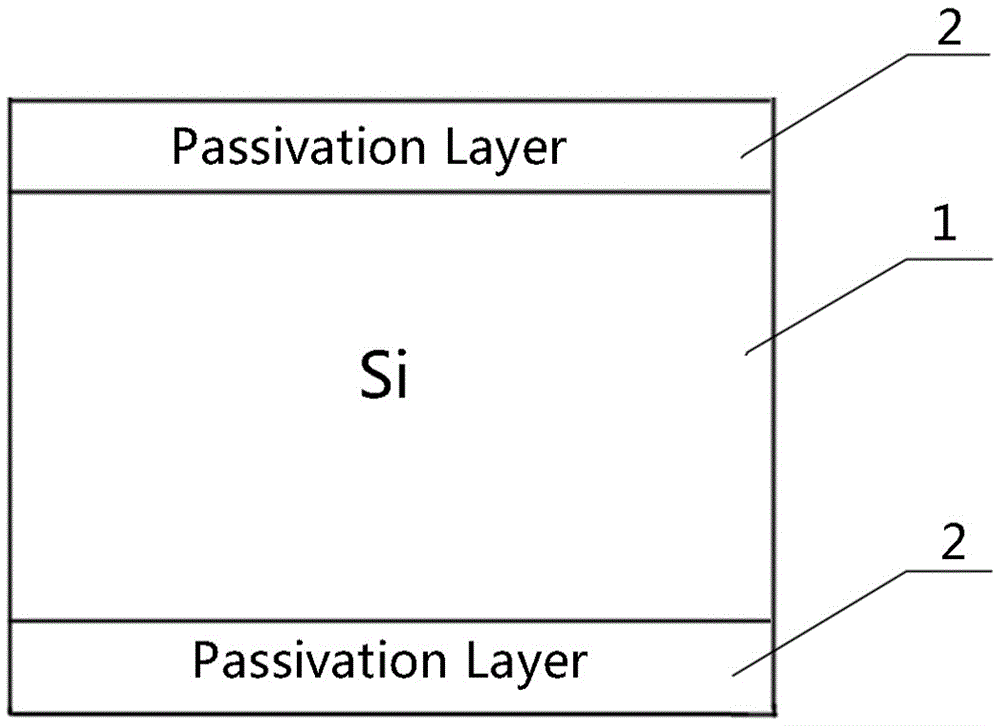

[0020] Such as figure 1 As shown, a passivation layer 2 is prepared on both the front surface and the back surface of the silicon wafer 1. The passivation layer 2 is a PSS film, and the PSS film can passivate the surface of the silicon wafer 1 very well. The thickness of the PSS thin film is on the order of nanometers. Preferably, the thickness of the PSS thin film is 30nm-1000nm. figure 1 What is shown in is just a specific example, and in other embodiments, the PSS film can also be formed on only one surface of the silicon wafer as a passivation layer. When the formed PSS film is used as a passivation layer, the passivation layer can fully cover the surface of the silicon wafer, or partially cover the surface of the silicon wafer, that is, the PSS film can be in partial contact with the surface of the silicon wafer, for example: to prepare a gate type The structured PSS film acts as a passivation layer.

[0021] The PSS thin film formed on the surface of the silicon wafer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com