Full-color display component for organic and inorganic quantum dot hybridization and preparing method thereof

A full-color display and inorganic technology, which is applied in the direction of organic semiconductor devices, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve the problems that the life and efficiency of blue light quantum dots cannot meet the use requirements, and achieve low processing costs and high-color display. The effect of high domain height and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

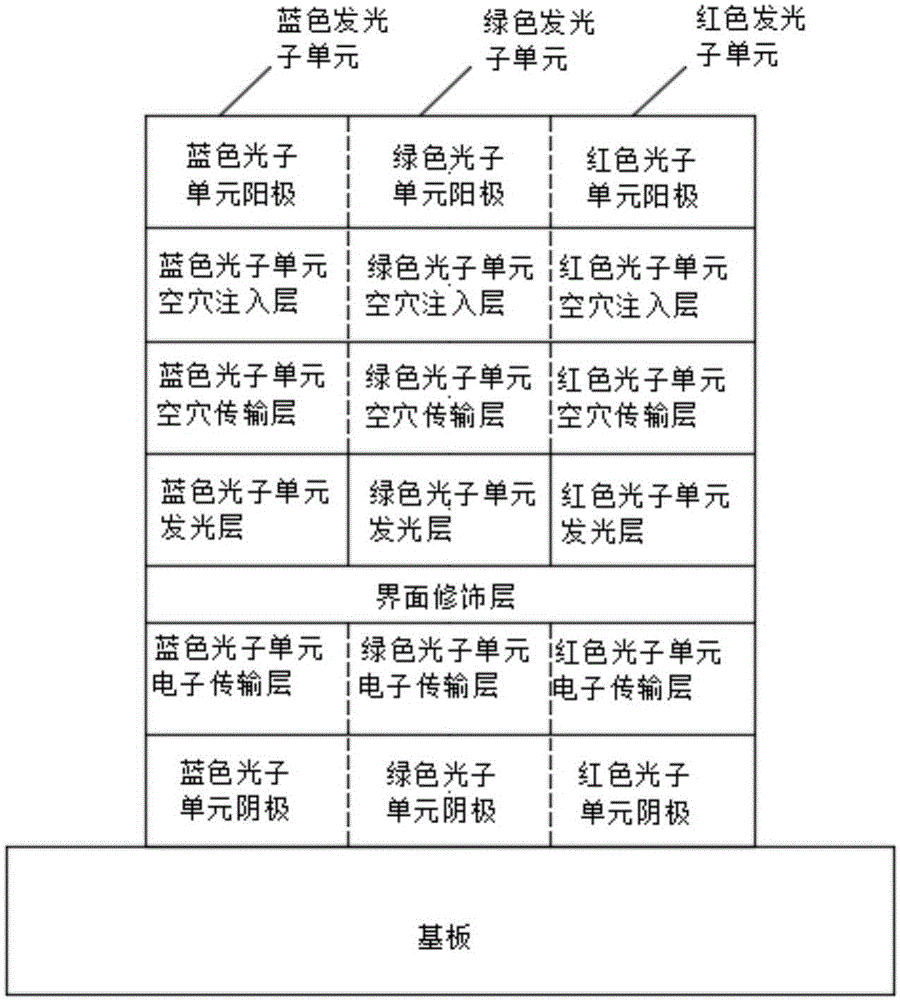

[0036] A full-color display device hybridized with organic and inorganic quantum dots in this embodiment, its structural schematic diagram is as follows figure 1 As shown, the light-emitting unit is included, and the light-emitting unit is fixedly installed on the substrate. The light-emitting unit includes a blue light-emitting subunit, a green light-emitting subunit, and a red light-emitting subunit; the blue light-emitting subunit sequentially includes a blue photon unit cathode, The blue photon unit electron transport layer, the blue photon unit light emitting layer, the blue photon unit hole transport layer, the blue photon unit hole injection layer and the blue photon unit anode, and the blue photon unit light emitting layer is an organic material; The red light-emitting subunit sequentially includes the cathode of the red photon unit, the electron transport layer of the red photon unit, the light-emitting layer of the red photon unit, the hole transport layer of the red ...

Embodiment 2

[0058] A full-color display device hybridized with organic and inorganic quantum dots in this embodiment, its structural schematic diagram is as follows figure 1 As shown, the light-emitting unit is included, and the light-emitting unit is fixedly installed on the substrate. The light-emitting unit includes a blue light-emitting subunit, a green light-emitting subunit, and a red light-emitting subunit; the blue light-emitting subunit sequentially includes a blue photon unit cathode, The blue photon unit electron transport layer, the blue photon unit light emitting layer, the blue photon unit hole transport layer, the blue photon unit hole injection layer and the blue photon unit anode, and the blue photon unit light emitting layer is an organic material; The red light-emitting subunit sequentially includes the cathode of the red photon unit, the electron transport layer of the red photon unit, the light-emitting layer of the red photon unit, the hole transport layer of the red ...

Embodiment 3

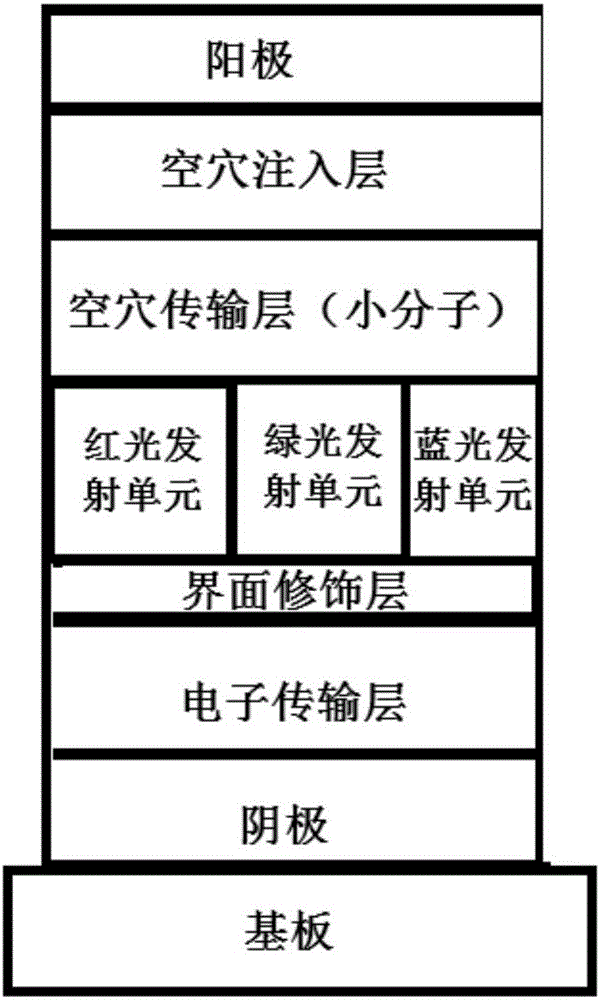

[0075] An organic and inorganic quantum dot hybrid full-color display device in this embodiment is specifically an inverted quantum dot LED device structure, and its structural diagram is as follows image 3 As shown, it includes cathode, electron transport layer, interface modification layer, red, green and blue light emitting unit, hole transport layer (small molecule), hole injection layer and anode.

[0076] The device uses organic polymer PFSO as the material of the blue light-emitting layer, and simultaneously as the hole transport layer of the quantum dot LED, and the rest of the materials are the same as those in Example 1. The whole device preparation process is as follows: (1) spin-coating and processing the electron transport layer; (2) spin-coating and processing the interface modification layer; (3) ink-jet printing to prepare the red light-emitting layer; (4) ink-jet printing to prepare the green light-emitting layer (5) inkjet printing (or spin coating) to prepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com