Gas-gas type heat exchanger

A gas-type heat exchanger, heat exchange tube technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., to achieve the effect of preventing shrinkage, low production cost, and high support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

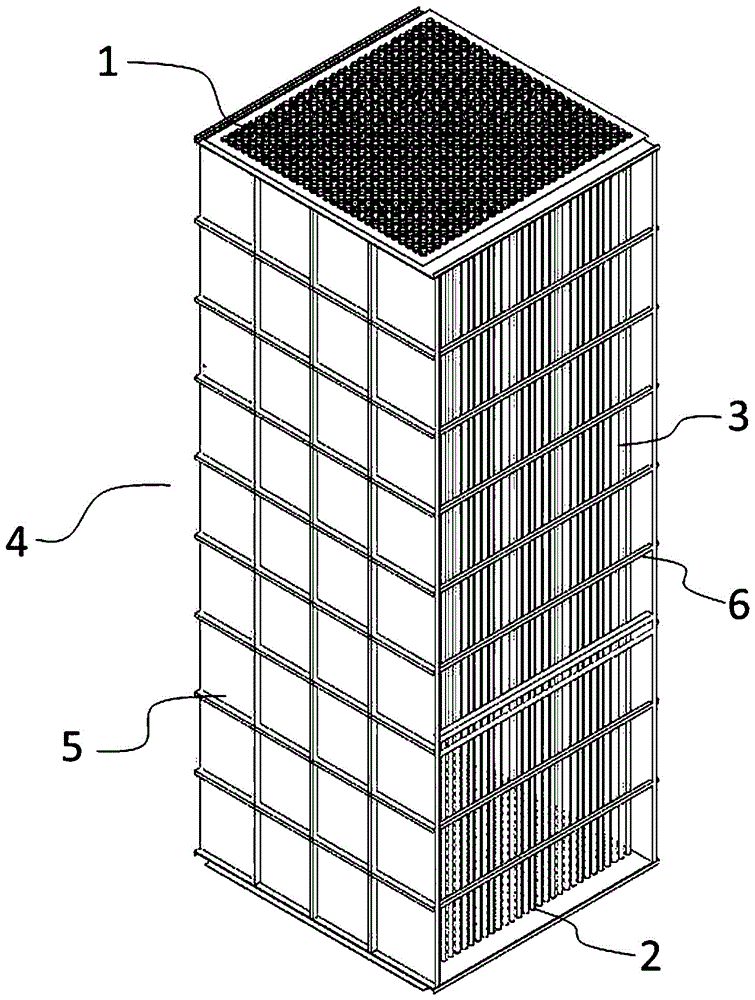

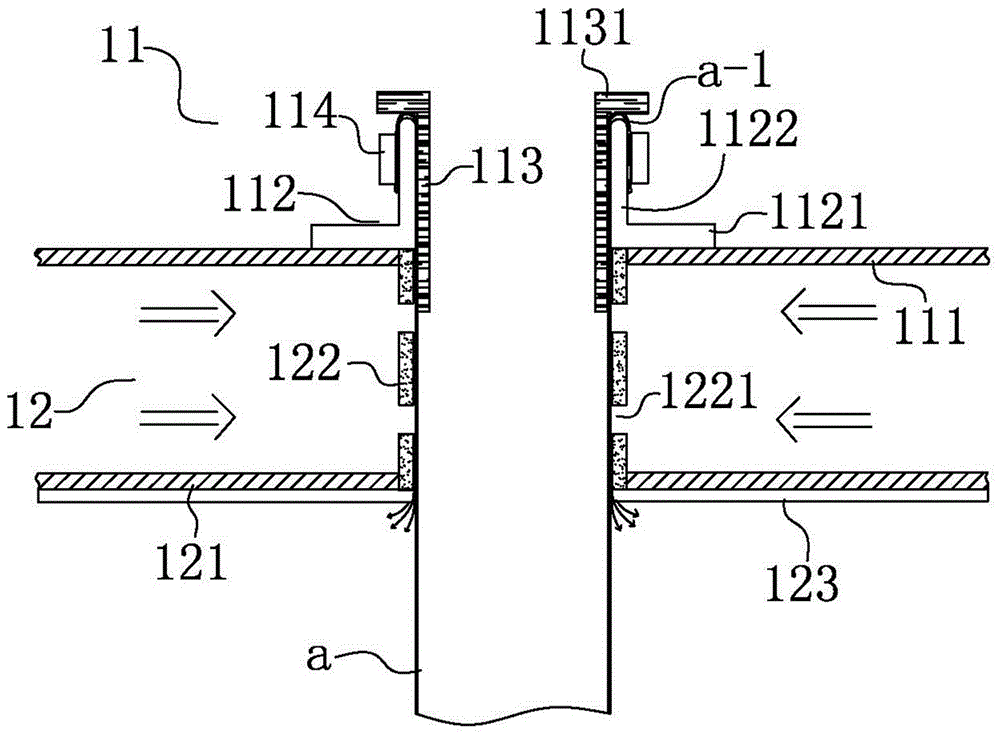

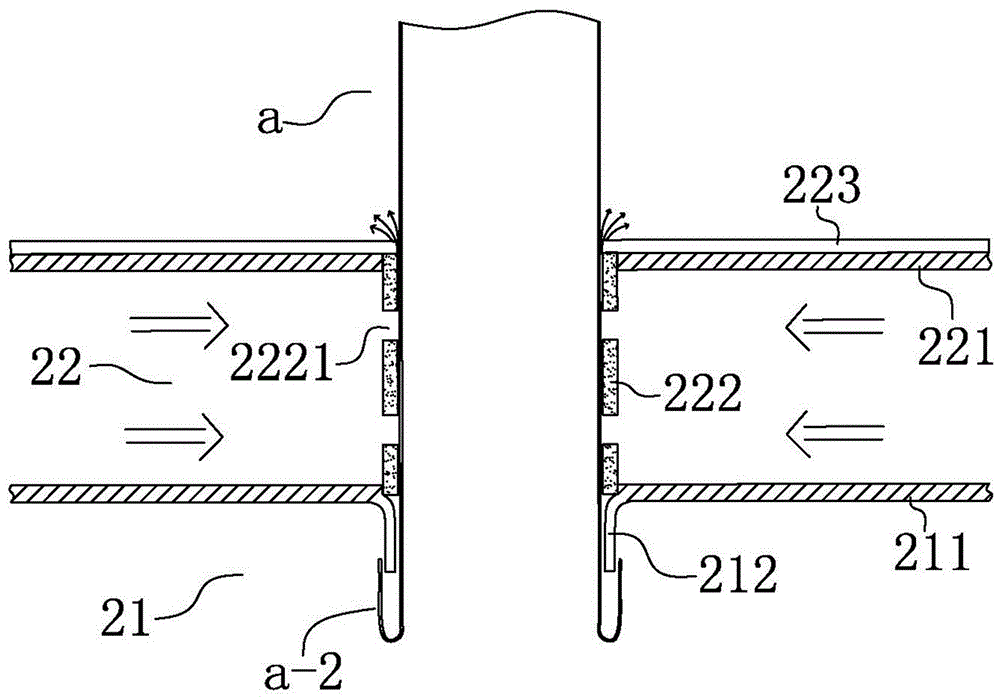

[0044] Example 1: Reference figure 1 , figure 2 and image 3 , a gas-gas heat exchanger, comprising an upper plate sealing part 1 at the upper end and a lower plate sealing part 2 at the lower end, and several sealing parts arranged between the upper plate sealing part 1 and the lower plate sealing part 2 A heat exchange tube a, the plurality of heat exchange tubes a form a heat exchange tube bundle, a shell side fluid inlet 3 and a shell side fluid outlet 4 are arranged around the heat exchange tube bundle, and the shell side fluid inlet 3 and the shell side fluid outlet 4 are arranged The side plate 5 separated by the shell side fluid outlet 4;

[0045] Several layers of heat exchange tube orifice plates 6 are arranged on the side plate 5 in the vertical direction, and the heat exchange tube orifice plates 6 are made of corrosion-resistant PTFE material, and the heat exchange tube a passes through the heat exchange tube The heat pipe orifice plate 6 is arranged in the he...

Embodiment 2

[0054] Example 2: Reference figure 1 , figure 2 and image 3 , and the difference from Embodiment 1 is that the support member 112 is a tooth clip, that is, the cylindrical support part 1122 includes several tooth-shaped vacancies.

Embodiment 3

[0055] Example 3: Reference figure 1 , figure 2 and image 3 , the difference from Example 1 is that the second upper orifice plate 121 is lined with an upper plate anti-corrosion layer 123; the second lower orifice plate 221 is lined with a lower plate anti-corrosion layer 223, the upper The plate anticorrosion layer 123 and the lower plate anticorrosion layer 223 are made of PTFE material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com