Herba artemisia selengensis vinegar beverage and preparation method thereof

A technology of vinegar drink and Artemisia sativa, which is applied in the field of Artemisia sativa vinegar drink and its preparation, which can solve the problems of lack of Artemisia sativa drinks, and achieve the effects of increasing product added value, soft taste, and mild vinegar taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

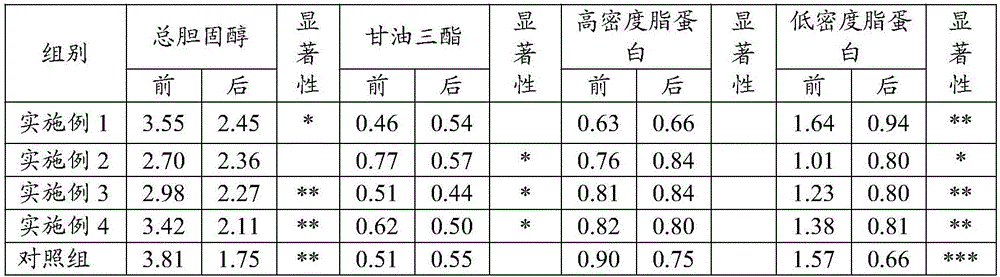

Examples

preparation example Construction

[0034] In the present invention, the dosage of the stock solution of wormwood vinegar drink is preferably 10-20%, more preferably 13-18%. Its specific preparation method comprises the following steps:

[0035] (1) Crushing and homogenizing Artemisia spp. and / or Artemisia spp. residues, mixing with 1-5 wt% cellulase for enzymatic hydrolysis;

[0036] (2) Sterilize after adjusting the sugar content of the enzymolyzed product obtained in the step (1) to 5-20%;

[0037] (3) inoculate saccharomycetes in the mixed material liquid that described step (2) sterilizes to obtain, airtight fermentation reaches more than 4% vol to alcohol content, obtains Artemisia argyi alcohol fermented mash, the inoculation volume of described saccharomycetes is described 0.5-6% of the volume of the mixture liquid;

[0038] (4) Insert acetic acid bacteria into the wormwood alcohol fermentation mash obtained in the step (3), ferment in the air environment, and ferment until the total acidity is greater...

Embodiment 1

[0061] The stems and leaves of Artemisia annua are mixed with water according to the ratio of material to liquid: 1kg:23L, distilled and extracted under boiling conditions for 4 hours, and the distilled steam is cooled to obtain the distillate of Artemisia annua.

[0062] Pulverize and homogenize the distillation residue of Artemisia arborescens obtained after distillation, mix it with cellulase of 3% of the total mass of the distillation residue of Artemisia annua at 45°C for enzymolysis, add white sugar to adjust the sugar content of the enzymolysis product to 15% , placed in the container and sterilized by indirect steam heating at 80°C for 15 minutes.

[0063] The sterilized mixed material liquid is inoculated with 4% yeast of the mixed material liquid volume, and the fermentation is closed at 27°C until the total sugar no longer changes. The alcohol content reaches more than 4% (vol), and the alcoholic fermentation of Artemisia argyi is obtained. mash.

[0064] Transfer ...

Embodiment 2

[0068] Grinding the young stems and leaves of Artemisia annua to obtain Artemisia annua juice.

[0069] Crush the stems and leaves of Artemisia argyi and mix them with homogenate. After homogenization, mix them with cellulase of 1% of the total mass of the distillation residue of Artemisia annua at 38°C for enzymolysis, add white sugar to adjust the sugar content of the enzymolysis product to 7%, and place Indirect steam heat sterilization at 60°C for 20 minutes in the container.

[0070] The sterilized mixed material liquid is inoculated with 3% yeast of the mixed material liquid volume, and the fermentation is closed at 25°C until the total sugar no longer changes, and the alcohol content reaches more than 4% (vol), and the alcoholic fermentation of Artemisia argyi is obtained. mash.

[0071] Transfer the Artemisia alcohol fermented mash into an open container, evenly sprinkle dry acetic acid bacteria with a volume of 0.05% of the Artemisia fermented mash on the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com