Treatment method for purifying industrial waste gas

A treatment method and technology for industrial waste gas, which are applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as unsatisfactory treatment effect, large equipment footprint, and unsuitable for small and medium-sized enterprises, and achieve the goal of being beneficial to large-scale enterprises. Scope of promotion and application, small equipment footprint, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

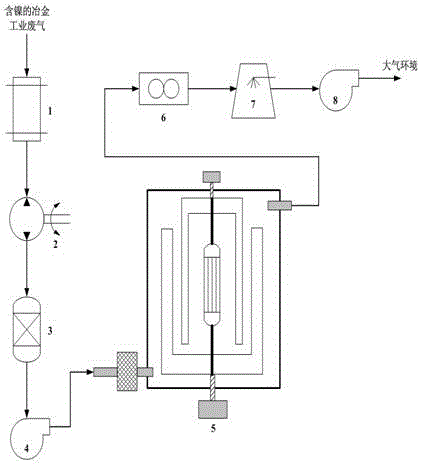

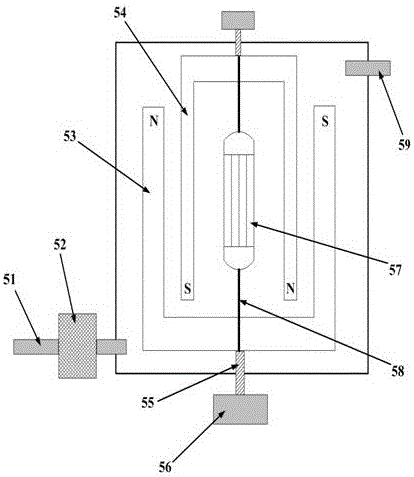

[0032] Such asfigure 1 The treatment method for removing metal nickel in metallurgical industry waste gas is shown. The metallurgical industry waste gas containing metal nickel enters the anti-shock protector 1 through the gas pipeline. Its function is to act as a pressure-resistant buffer when the flow and pressure of the waste gas are unstable. The function is to protect the back-end processing equipment. The outlet of the anti-shock protector 1 is connected to the multi-parameter gas tester 2 through the gas pipeline. Real-time monitoring, the outlet of the multi-parameter gas tester 2 is connected to the alkali elution acid device 3 through the gas pipeline, and the alkali elution acid device 3 uses calcium hydroxide solution to carry out alkali washing and neutralization of the waste gas containing acidic substances such as hydrogen chloride to protect The back-end processing equipment is not corroded by acidic substances. The outlet of the alkali-eluting acid device 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com