Purification device and process of sludge drying and granulation waste gas

A waste gas purification device and sludge drying technology, which is used in gas treatment, dispersed particle separation, air quality improvement and other directions, can solve the problems of high cost and low efficiency, and achieve low cost, wide temperature range and high purification efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

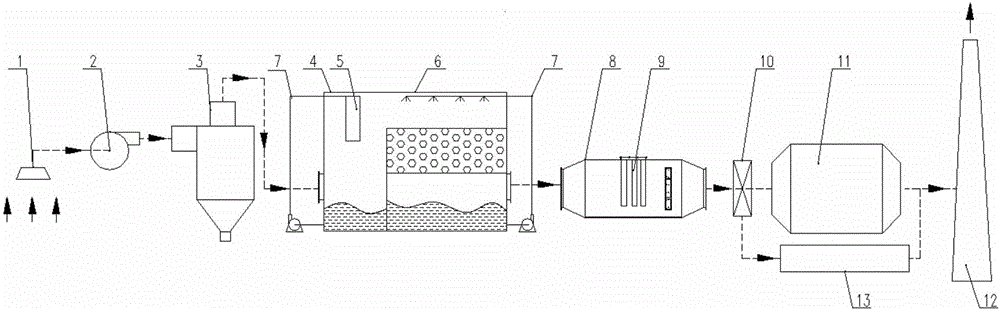

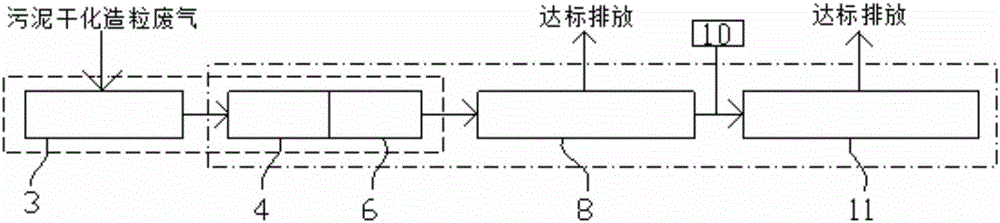

[0027] see figure 1 , a sludge drying and granulation exhaust gas purification device in the illustration is a preferred embodiment of the present invention, specifically including an exhaust gas collection module 1, an induced draft fan 2, a dust removal module 3, a spray cooling and dust removal section 4, and a microbubble generator 5. Biological purification section 6, circulating fluid system 7, high-energy ion purifier 8, high-energy ion tube 9, switching valve 10, adsorption purifier 11, exhaust module 12 and bypass 13.

[0028] Specifically, in this embodiment, during the purification process of sludge drying and granulation waste gas, the biological waste gas collection module 1, induced draft fan 2, dust removal module 3, spray cooling and dust removal section 4 and biological purification section 5 are collected through the air duct. The purification module, the high-energy ion purifier 8, the adsorption purifier 11 and the exhaust tube 12 are connected in series. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com