Preparation method of collagen/chitosan imprinted material

An imprinting material, chitosan technology, applied in chemical instruments and methods, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of easy acid solubility, low strength, limited metal ion chelating ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

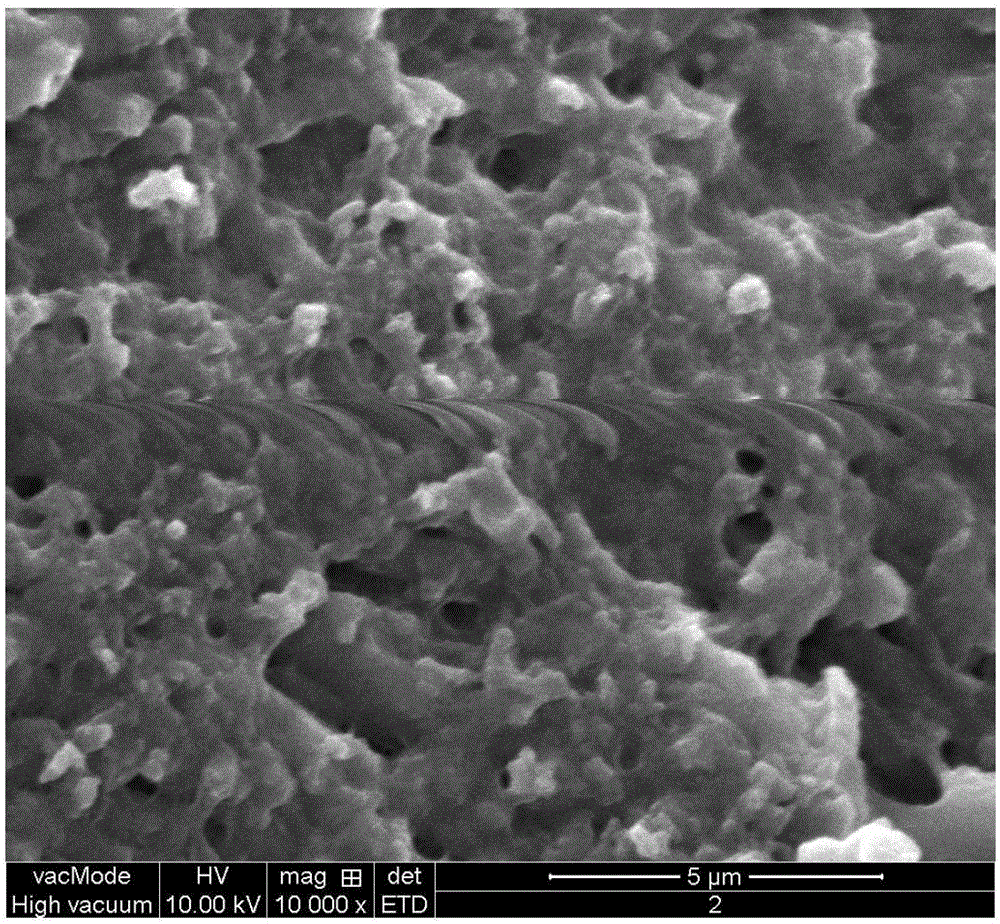

Image

Examples

Embodiment 1

[0020] Dissolve 0.5g chitosan and 0.5g collagen fibers in 20ml acetic acid solution and stir for 2h until the solution is transparent, slowly add 0.05g EDTA to the solution, stir at room temperature for 2 hours, add 2ml glutaraldehyde / formaldehyde solution dropwise and stir for 1h , add 12.5ml of 0.8g / L copper sulfate solution and stir for 1 hour to form a blue gel. Finally, dry at a low temperature of 50°C to obtain the collagen / chitosan imprinted material.

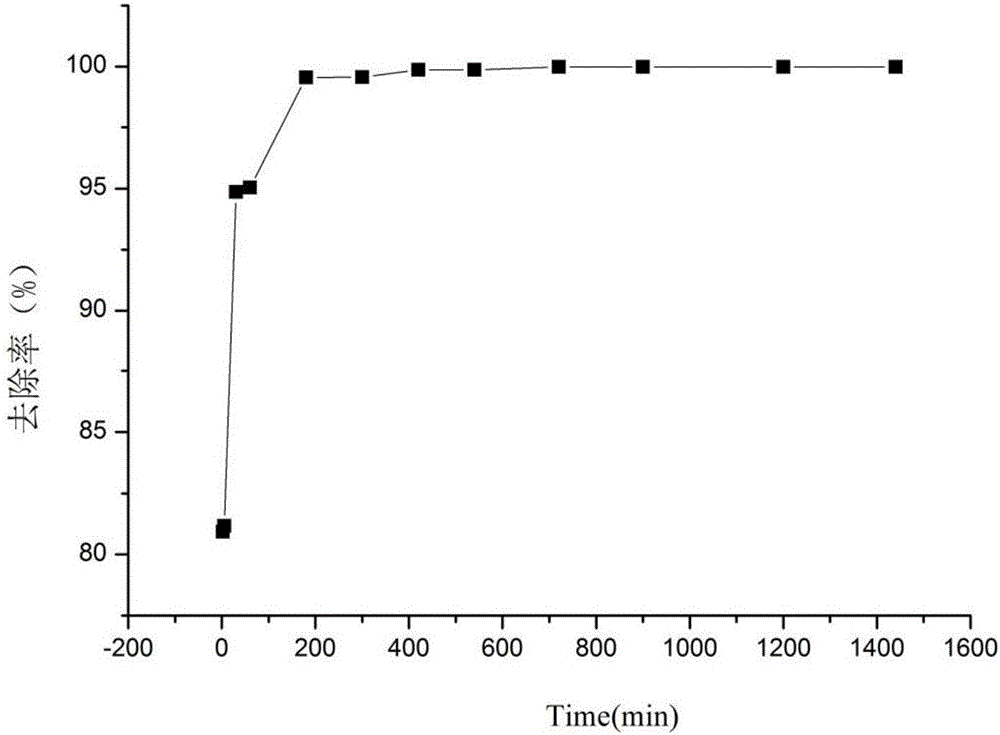

[0021] Add 0.01g of collagen / chitosan imprinting material to 50ml of Cu(II) solution with an initial concentration of 100mg / L, shake for 24 hours, filter and separate, take the supernatant and use the copper ion electrode method to measure the residual Cu(II) concentration of the solution , The calculated removal rate is 99%.

Embodiment 2

[0023] Dissolve 0.5g chitosan and 0.8g collagen fibers in 20ml acetic acid solution and stir for 2h until the solution is transparent, slowly add 0.1g EDTA to the solution, stir for 2 hours at room temperature, add 2ml glutaraldehyde / formaldehyde solution dropwise and stir for 2h , add 12.5ml of 0.8g / L copper sulfate solution and stir for 2 hours to form a blue gel. After drying at 50°C, the collagen / chitosan imprinted material was obtained.

[0024] Add 0.01g of collagen / chitosan imprinting material to 50ml of Cu(II) solution with an initial concentration of 100mg / L, shake for 24 hours, filter and separate, take the supernatant and use the copper ion electrode method to measure the residual Cu(II) concentration of the solution , The calculated removal rate is 99%.

Embodiment 3

[0026] Dissolve 0.5g chitosan and 1.0g collagen fibers in 20ml acetic acid solution and stir for 2h until the solution is transparent, slowly add 0.2g EDTA to the solution, stir for 2 hours at room temperature, add 2ml glutaraldehyde / formaldehyde solution dropwise and stir for 2h , add 10ml of 1g / L copper sulfate solution and stir for 2 hours to form a blue gel. After drying at 50°C at low temperature, soak and wash off the blue color with 0.1mol / L hydrochloric acid solution and 0.1mol / L sodium hydroxide solution respectively. Dry at 50°C to obtain collagen / chitosan imprinted material

[0027] Take 0.01g of collagen / chitosan imprinting material and add it to 50ml of Cu(II) solution with an initial concentration of 200mg / L, shake for 24 hours, filter and separate, take the supernatant and use the copper ion electrode method to measure the residual Cu(II) concentration of the solution , The calculated removal rate is 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com