High-deposition-rate and low-hydrogen type iron powder electrode and preparation method thereof

A technology of iron powder electrode and low hydrogen type, which is applied in the field of high deposition rate and low hydrogen type iron powder electrode and its preparation, can solve the problems of mechanical properties and deposition efficiency to be improved, and achieve ideal weld hardness and numerical fluctuation Small size and high deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

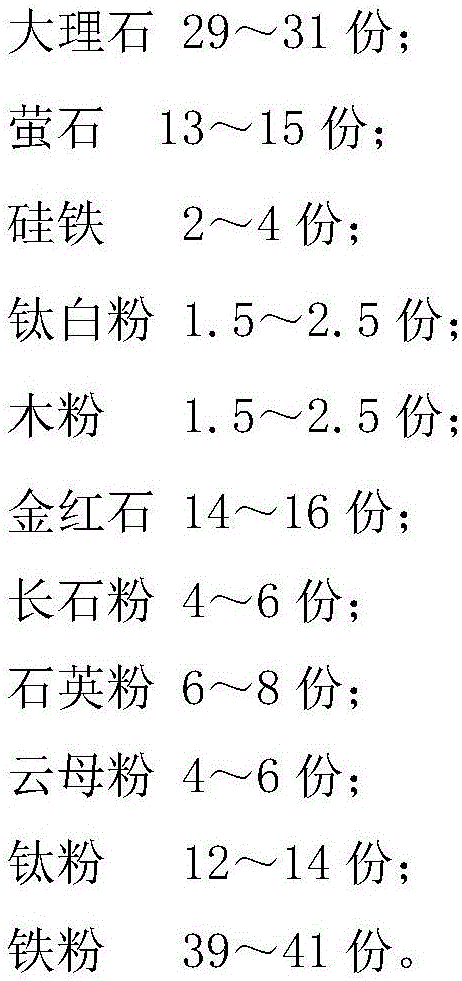

[0114] The preparation method of the above-mentioned high deposition rate low hydrogen type iron powder electrode comprises the following steps:

[0115] a. Welding core treatment: Grind the prepared welding core with sandpaper, clean the surface of the welding core, make the surface of the welding core clean and smooth, straighten it, and weigh it;

[0116] b. Passivation treatment of iron alloy: in the atmospheric environment, the iron-containing components in the coating are oxidized and passivated;

[0117] Generally, one or more kinds of iron alloys are added to the electrode coating, especially the basic electrode, which contains more iron alloys. These iron alloy powders will interact with the free alkali in the water glass during the wet mixing process, and the following can occur reaction:

[0118] Hydrolysis of water glass:

[0119] Na 2 SiO 3 +2H 2 O=2NaOH+H 2 SiO 3

[0120] The ferrosilicon added in the paint contains elemental silicon Si, so:

[0121] Si+...

Embodiment 1

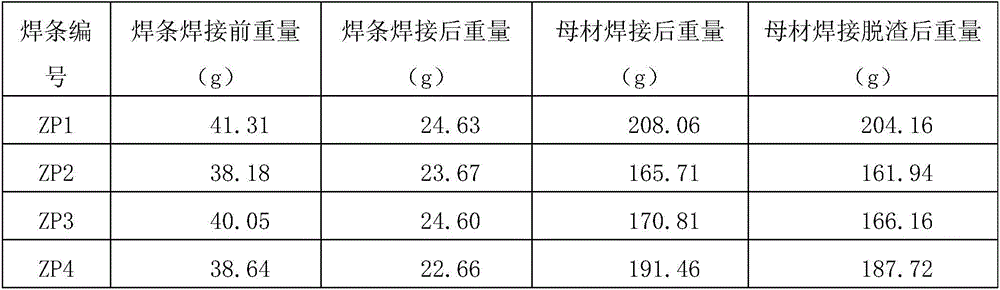

[0135] 1, the following only select the most representative several groups of experiments in a large number of experiments, to prove that the electrode coating formula selected by the present invention has higher deposition efficiency and hardness, the specific experimental steps are as follows:

[0136] (1) Welding core treatment: Grind the pre-prepared H08A welding core (see Table 1 for its chemical composition) with sandpaper until the surface of the welding core is bright, straighten it, and weigh it;

[0137] Table 1 Chemical composition of H08A welding core ( / wt%)

[0138] chemical composition C Si mn P S Ni Cr Solder core H08A ≤0.10 ≤0.03 0.30~0.55 ≤0.03 ≤0.03 ≤0.30 ≤0.20

[0139] (2) Passivation treatment of ferroalloys: the natural passivation method is adopted to oxidize ferroalloys in the atmosphere;

[0140] (3) Modulation of water glass: in the water glass blending pool, adjust to the required concentration, and add 0.25% to 0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com