Hook-face polisher

A polishing machine and curved surface technology, applied in the field of polishing machines, can solve the problems of low usage rate of processing consumables, poor consistency of the entire plate workpiece, low yield rate of workpieces, etc., and achieve the effects of improving yield rate, uniform loss, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

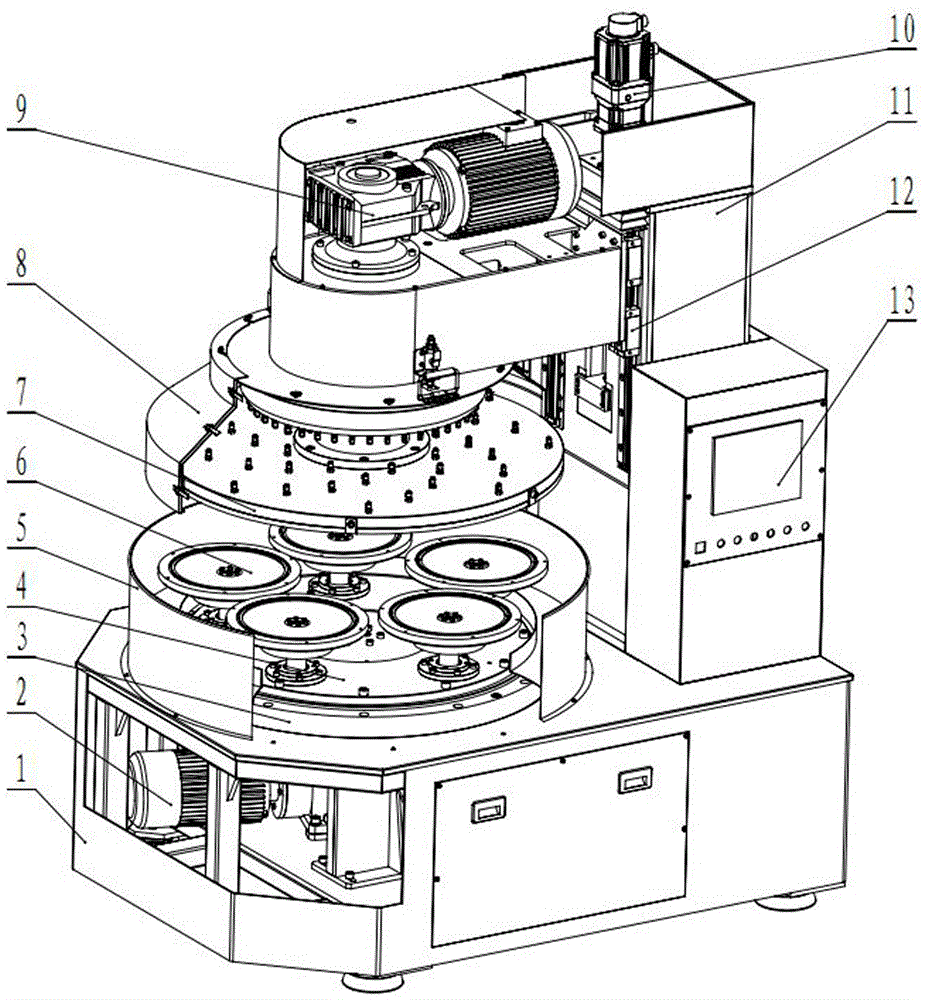

[0012] Such as figure 1 As shown, the curved surface polishing equipment of the present invention includes a bed 1, a lower plate power system 2, a slewing bearing support assembly 3, a revolution plate 4, a liquid receiving basin 5, a workpiece plate assembly 6, an upper plate assembly 7, a liquid shield 8, Various functional modules such as the upper plate power system 9, the servo feed system 10, the column component 11, the linear slider assembly 12, and the numerical control system 13. The bed 1 is provided with a bottom plate power system 2, and the bottom plate power system 2 mainly provides the revolution movement of the workpiece plate; the bed 1 is provided with a slewing bearing support assembly 3 connected with the bottom plate power system 2, The revolving disk 4 is supported by the slewing bearing support assembly 3, and the revolving disk 4 is evenly provided with five workpiece disk assemblies 6 that are connected to the lower plate power system 2 and can rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com