Super-hard cutting blade and preparation method thereof

A cutting blade, superhard technology, used in manufacturing tools, metal processing equipment, grinding/polishing equipment, etc., can solve the problem of high cost, achieve the effect of long service life, strong bonding and good cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The present embodiment provides a kind of preparation method of superhard cutting sheet, it comprises the following steps:

[0024] Preparation of superhard cutting sawtooth: first, sandblasting the cutting sawtooth matrix made of 65 manganese steel to obtain the sandblasted cutting sawtooth matrix; immersing the sandblasted cutting sawtooth matrix in 8wt% hydrochloric acid solution to obtain pickling and cutting the sawtooth substrate; immersing the pickling and cutting sawtooth substrate in an alkali cleaning solution with a temperature of 80°C for 10 minutes; the alkali cleaning solution is NaOH solution and Na 2 CO 3 Mixing of the solution; then the Ni-based solder powder with an average particle size of 10 microns to 200 microns is mixed with diamond particles with an average particle size of 3 microns to 50 microns to prepare a mixed brazing material powder; the mixed brazing The welding material powder is pre-coated on the surface of the cutting sawtooth substra...

Embodiment 2

[0028] This embodiment provides a method for preparing a superhard cutting sheet, and the specific steps are roughly the same as those in Example 1, except that:

[0029] The brazing filler metal powder is Cu-based brazing filler metal powder; the superhard material particles are boron nitride particles; the cutting sawtooth substrate is No. 45 steel; the cutting blade substrate is No. 45 steel.

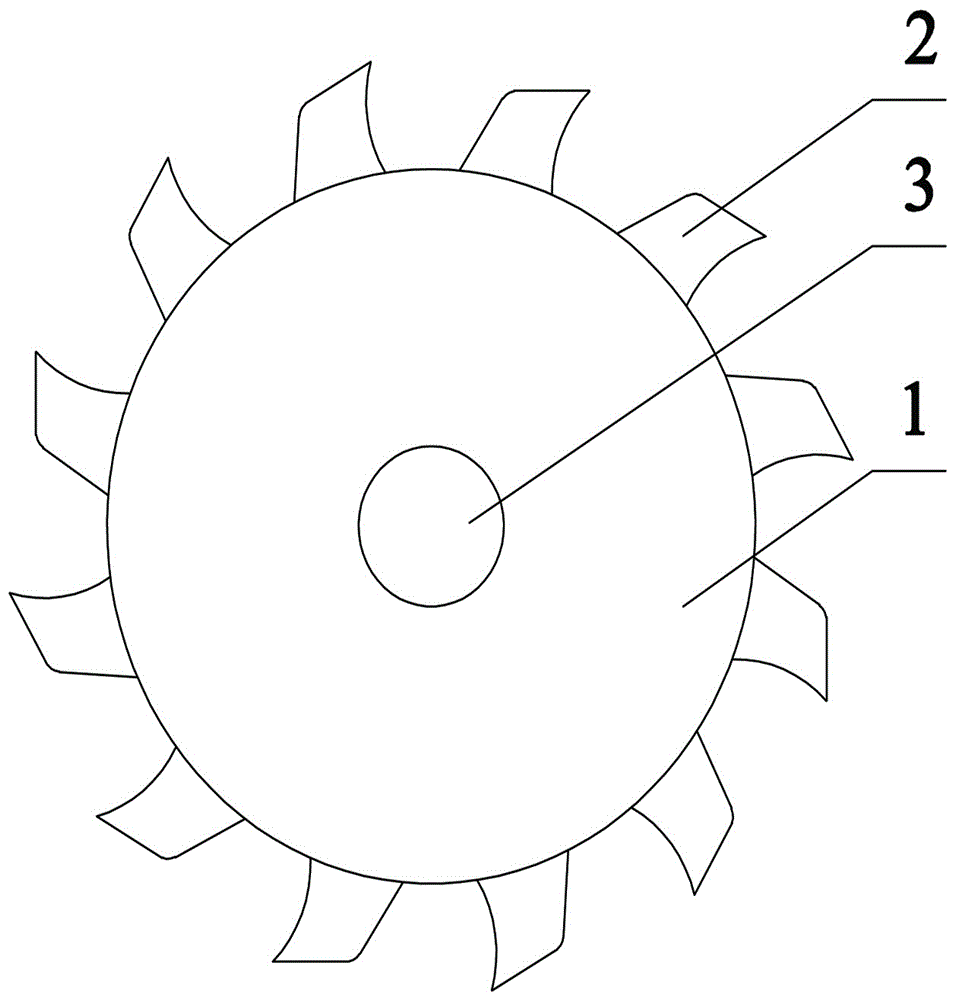

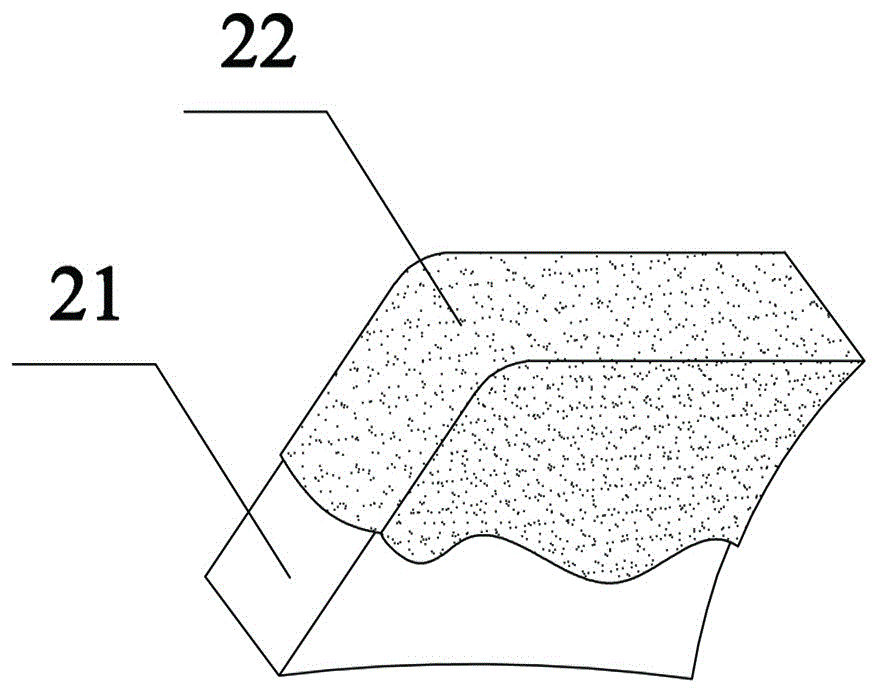

[0030] This embodiment also provides a superhard cutting blade made by the above preparation method, which includes a cutting blade base 1 made of No. 45 steel and superhard cutting sawtooth 2 welded on the cutting blade base 1; An assembly hole 3 is opened in the center of the cutting disc base 1 . The superhard cutting sawtooth 2 includes a cutting sawtooth base 21 of No. 45 steel and a boron nitride layer welded on the outer surface of the cutting sawtooth base by vacuum brazing.

Embodiment 3

[0032] This embodiment provides a method for preparing a superhard cutting sheet, and the specific steps are roughly the same as those in Example 1, except that:

[0033] The brazing filler metal powder is a combination of Ni-based brazing filler metal powder and Ag-based brazing filler metal powder; the superhard material particles are boron nitride particles; the cutting sawtooth substrate is No. 45 steel; the cutting blade substrate For 45 steel.

[0034] This embodiment also provides a superhard cutting blade made by the above preparation method, which includes a cutting blade base 1 made of No. 45 steel and superhard cutting sawtooth 2 welded on the cutting blade base 1; An assembly hole 3 is opened in the center of the cutting disc base 1 . The superhard cutting sawtooth 2 includes a cutting sawtooth base 21 of No. 45 steel and a boron nitride layer welded on the outer surface of the cutting sawtooth base by vacuum brazing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com