Packaging bag and method for preventing agglomeration of powder

A technology for packaging bags and powders, applied in the field of powder preparation and storage, can solve problems such as lack of general applicability, introduction of foreign bodies, and reduction of product purity, and achieve the effect of preventing agglomeration, wide application and solving agglomeration problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

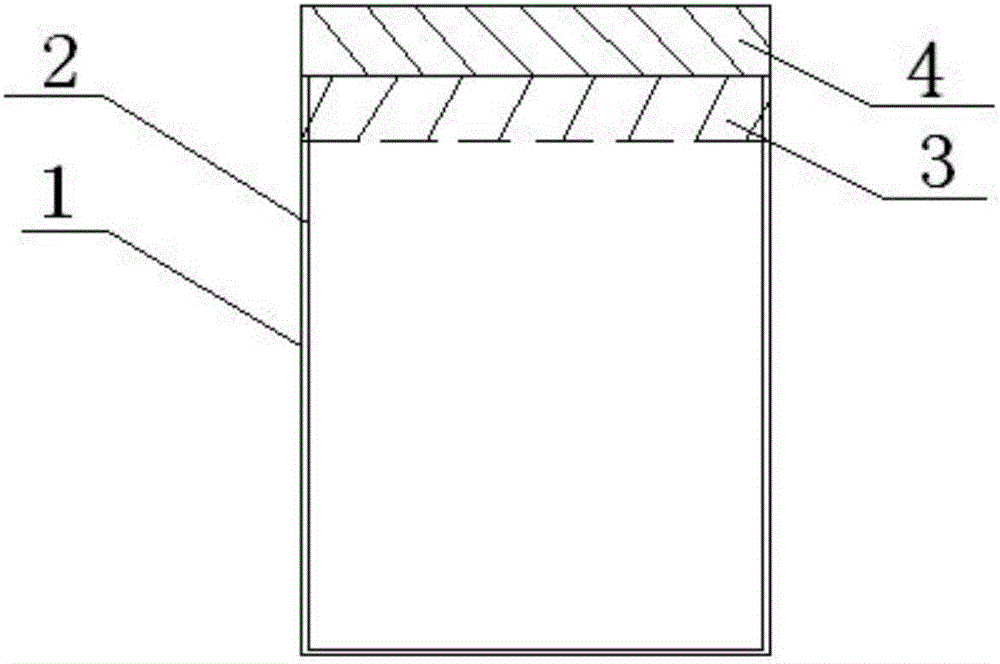

[0036] The size of the packaging bag is 800mm*550mm, the inner packaging bag is made of imported crepe paper, and the outer packaging bag is made of polyethylene terephthalate. The top of the inner packaging bag is 2cm lower than the top of the outer packaging bag, and the 5cm width section at the top of the inner packaging bag is combined with the outer packaging bag to form a fixed composite section.

[0037] In the inner layer packaging bag of packaging bag, the micropowder grade lithium carbonate product of packing into 20Kg, the D50 of lithium carbonate product is 6.7 μ m, keeps the air volume under the natural state in the bag, carries out the heat of 1.8cm on the top of outer layer packaging bag Seal to form a heat-sealing segment to obtain a packaged product.

[0038] Stack the packaged products, 1 ton / pallet, one pallet. One month later, all the packaging bags containing the product were well sealed and undamaged, and no agglomeration was found in the product after o...

Embodiment 2

[0040] The packaging bag with a specification of 800mm*550mm, the inner packaging bag is made of lithographic ES non-woven fabric, and the outer packaging bag is made of high-density polyethylene. The top of the inner packaging bag is 10cm lower than the top of the outer packaging bag, and the 18cm width section at the top of the inner packaging bag is combined with the outer packaging bag to form a fixed composite section.

[0041] Pack 20Kg of micronized lithium carbonate product into the inner packaging bag of the packaging bag, the D50 of the lithium carbonate product is 7.6 μm, keep the air volume in the natural state in the bag, and heat seal the top of the outer packaging bag with 4cm A heat-sealed section is formed to obtain a packaged product.

[0042] Stack the packaged products, 1 ton / pallet, stacking two pallets. After 6 months, all the packaging bags containing the product were well sealed and undamaged, and no agglomeration was found in the product after opening...

Embodiment 3

[0044] The size of the packaging bag is 800mm*550mm, the inner packaging bag is made of domestic raw pulp paper, and the outer packaging bag is made of aluminum-plastic film. The top of the inner packaging bag is 20cm lower than the top of the outer packaging bag, and the 25cm width section at the top of the inner packaging bag is combined with the outer packaging bag to form a fixed composite section.

[0045] Pack 20Kg of micronized lithium carbonate product into the inner packaging bag of the packaging bag, the D50 of the lithium carbonate product is 9.3 μm, keep the air volume in the natural state in the bag, and heat seal the top of the outer packaging bag with 10cm A heat-sealed section is formed to obtain a packaged product.

[0046] Stack the packaged products, 1 ton / pallet, three pallets. After 12 months, all the packaging bags containing the product were well sealed and undamaged, and no agglomeration was found in the product after opening the package.

[0047] In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com