Fungus-algae symbiosis-based high-efficiency biogas liquid purifying method

An algal-bacterial symbiosis, biogas slurry technology, applied in chemical instruments and methods, biological water/sewage treatment, sedimentation treatment, etc. Application prospect, simple reaction process, high utilization value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

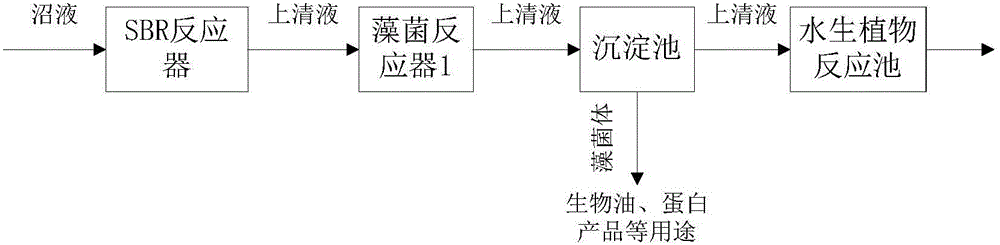

Image

Examples

Embodiment 1

[0031] Embodiment 1 The method for purifying biogas slurry of the present invention

[0032] One, the inventive method

[0033] a. SBR reaction

[0034] Reaction device: SBR reactor;

[0035] Process: Take the biogas slurry, add it to the SBR reactor, inoculate the activated sludge, the volume of the activated sludge is 1 times the volume of the biogas slurry, aerate the treatment until the pH drops to 6.5-7.0, and naturally settle for 4 hours to obtain the supernatant 1;

[0036] Among them, the aeration treatment is intermittent aeration, the cycle of intermittent aeration is 6h / 6h, the treatment time is 24h, and the aeration volume is 0.2L / L·min;

[0037] b. Algae reaction

[0038] Reaction device: open runway pool; vertical flow sedimentation tank;

[0039] Process: put the supernatant 1 obtained in step a into an open raceway pool, inoculate Chlorella, culture under stirring conditions for 10 days, discharge it into a vertical flow sedimentation tank, and naturally se...

Embodiment 2

[0054] Embodiment 2 The method for purifying biogas slurry of the present invention

[0055] One, the inventive method

[0056] a. SBR reaction

[0057] Reaction device: SBR reactor;

[0058] Process: Take biogas slurry, add it to SBR reactor, inoculate activated sludge, the volume of activated sludge is 0.4 times the volume of biogas slurry, aerate the treatment until the pH drops to 6.5-7.0, and naturally settle for 2 hours to obtain supernatant 1;

[0059] Among them, the aeration treatment is intermittent aeration, the cycle of intermittent aeration is 6h / 6h, the treatment time is 12h, and the aeration volume is 0.2L (air) / L (biogas slurry) min;

[0060] b. Algae reaction

[0061] Reaction device: airlift reactor; vertical flow sedimentation tank;

[0062] Process: put the supernatant 1 obtained in step a into the photobioreactor, inoculate Scenedesmus, culture under aeration conditions for 5-10 days, discharge it into a vertical flow sedimentation tank, and naturally se...

Embodiment 3

[0076] Embodiment 3 The method for purifying biogas slurry of the present invention

[0077] One, the inventive method

[0078] a. SBR reaction

[0079] Reaction device: SBR reactor;

[0080] Process: Take biogas slurry, add it to SBR reactor, inoculate activated sludge, the volume of activated sludge is 1.5 times the volume of biogas slurry, aerate until the pH drops to 6.5-7.0, and naturally settle for 6 hours to obtain supernatant 1;

[0081] Among them, the aeration treatment is intermittent aeration, the cycle of intermittent aeration is 6h / 6h, the treatment time is 36h, and the aeration volume is 0.2L / L·min;

[0082] b. Algae reaction

[0083] Reaction device: bubble reactor; vertical flow sedimentation tank;

[0084] Process: put the supernatant 1 obtained in step a into a photobioreactor, inoculate Botrytis bransiella, cultivate it under aeration conditions for 5-10 days, discharge it into a vertical flow sedimentation tank, and let it settle naturally for 0.5 days...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com