Method of refining ambroxol hydrochloride for injection

A technology for ambroxol hydrochloride and ambroxol hydrochloride crude product, applied in the refining field of ambroxol hydrochloride for injection, can solve the problems such as high recovery cost of refined mother liquor, unsuitability for recovery and re-refining, waste of raw materials and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

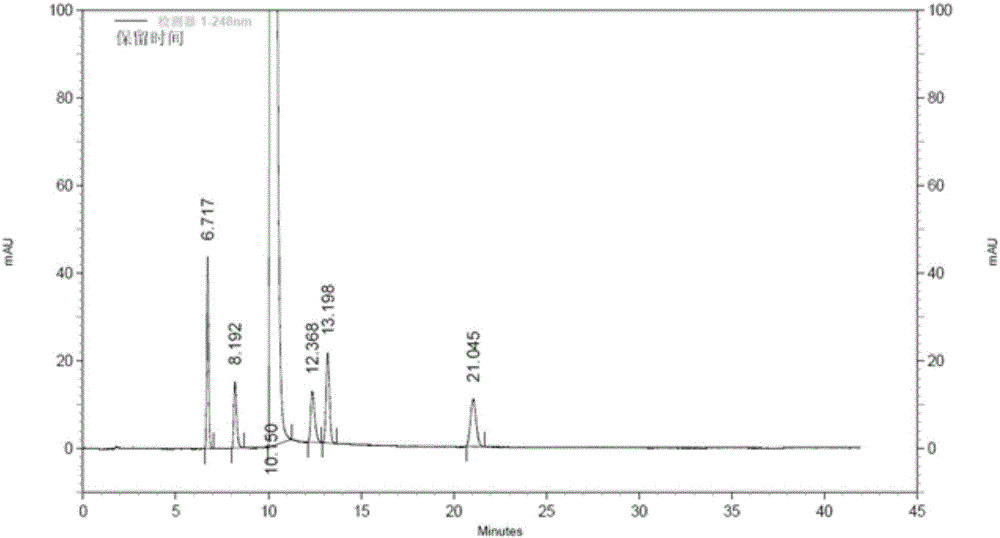

Embodiment 1

[0041] A method for refining ambroxol hydrochloride for injection, comprising the following steps: heating and refluxing the crude product of ambroxol hydrochloride with aqueous hydrochloric acid to dissolve, filtering, taking the filtrate for recrystallization, washing, and drying to obtain ambroxol hydrochloride for injection.

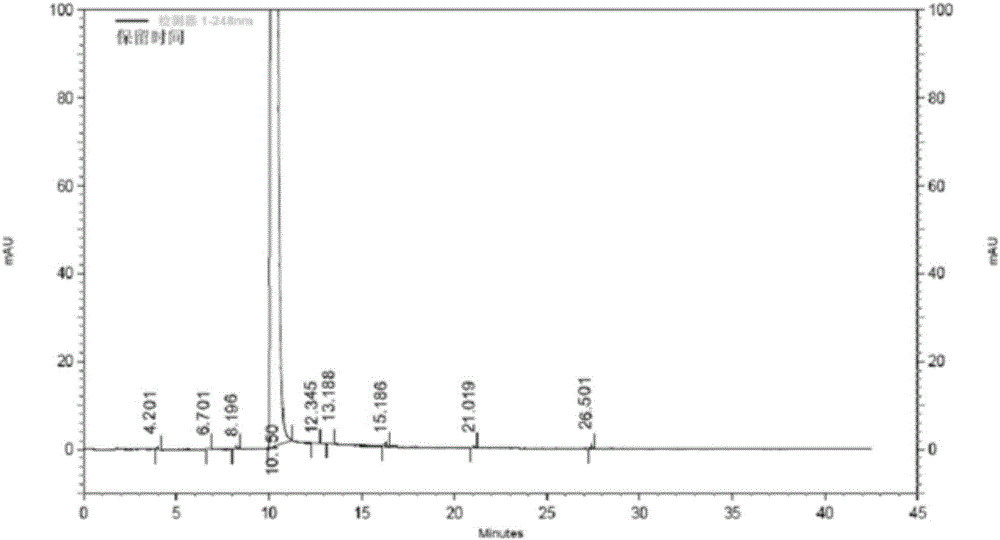

Embodiment 2

[0043] A method for refining ambroxol hydrochloride for injection, comprising the steps of: 1 kg of ambroxol hydrochloride crude product is heated and refluxed to dissolve with 0.01mol / L hydrochloric acid aqueous solution with a concentration of 8 L, filtered while hot, and the filtrate is stirred and cooled to 73.5° C., added Seed crystal 1g, stir and cool down to 30°C within 2h, then stop stirring, cool down to 0°C, stand for crystallization for 2h, filter to take the filter cake, wash with 200ml of water at 0°C, adjust the vacuum degree to 0.09MPa, adjust Temperature to 80° C., drying for 3 hours to obtain 0.91 kg of ambroxol hydrochloride for injection, the yield was 91.0%, and the purity was 100%.

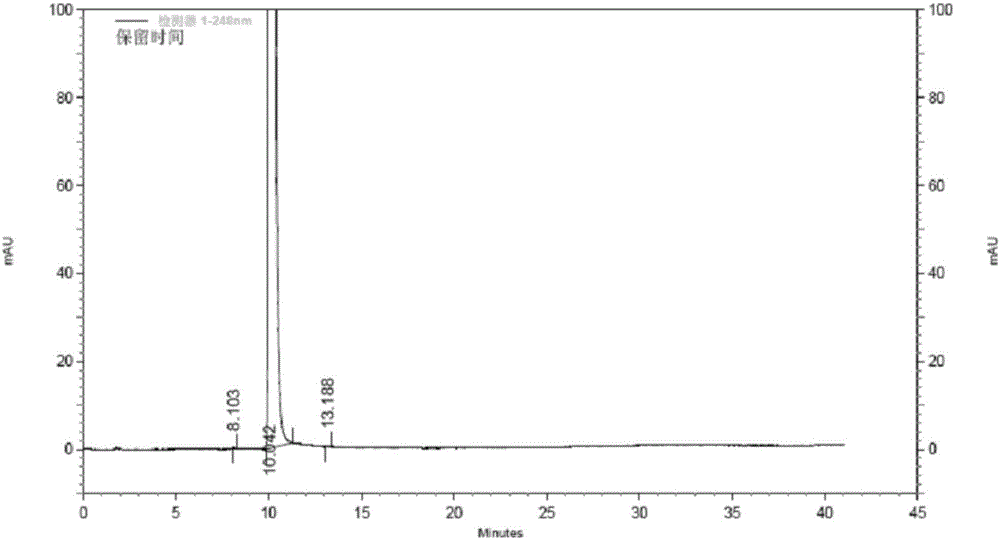

Embodiment 3

[0045] A method for refining ambroxol hydrochloride for injection, comprising the steps of: 3kg of ambroxol hydrochloride crude product is heated and refluxed to dissolve with 27L concentration of 0.02mol / L hydrochloric acid aqueous solution, filtered while hot, and the filtrate is stirred and cooled to 72.5°C, added Seed crystal 1g, stir and cool down to 25°C within 3h, then stop stirring, cool down to 5°C, stand for crystallization for 3h, filter to get the filter cake, wash with 1L of water at 5°C, adjust the vacuum degree to 0.1MPa, adjust Temperature to 75°C, drying for 4h to obtain 2.74kg of ambroxol hydrochloride for injection, the yield was 91.3%, and the purity was 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com