Continuous crystallization device and method for trichlorfon technical

A crystallization device, the technology of trichlorfon, applied in the field of continuous crystallization device of trichlorfon technical, can solve the problems of accelerated coagulation speed, short process flow, blockage of distributor, etc., achieves shortened crystallization period, high crystallization quality, and saves The effect of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

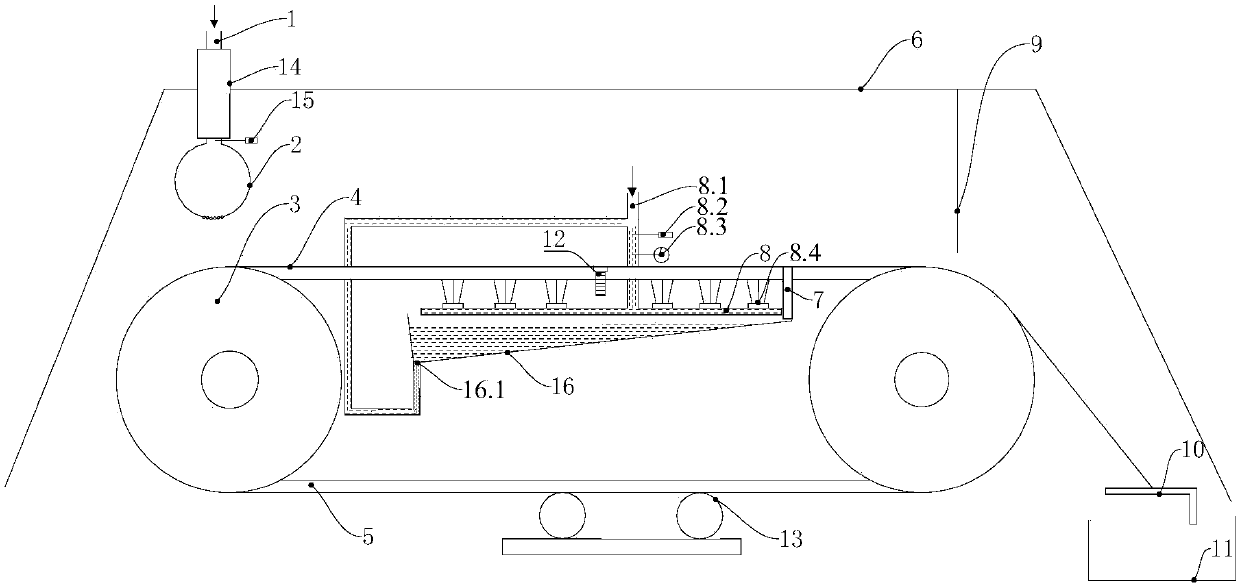

[0025] In order to better understand the present invention, the invention will be described in detail below in conjunction with the accompanying drawings and specific examples.

[0026] Such as figure 1 As shown, the continuous crystallization device of trichlorfon technical comprises a steel strip 4, a transfer roller 3 for conveying the steel strip 4 and a cooling device 8 for cooling the steel strip 4, and a cloth is arranged above the feeding end of the steel strip 4. 2, the distributor 2 is connected with the feed pipe 1, and the outer periphery of the feed pipe 1 is provided with a heat tracing device 14; the lower part of the steel belt 4 is provided with a cooling device 8, and the discharge end of the steel belt 4 is provided with a discharge device 9. The discharge end of the steel belt 4 is connected to the pulverizer 10, and a storage tank 11 is arranged below the pulverizer 10.

[0027] Among them, the lower end of the feed pipe 1 is provided with a first thermom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com