Betaine type zwitterionic polymer antifogging coating and preparation method thereof

A zwitterion, anti-fog coating technology, applied in the direction of coating, can solve the inconvenience and harm of human life, reduce light transmittance, light scattering and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

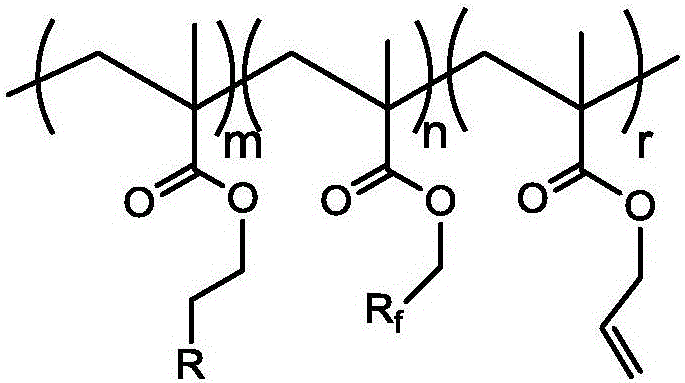

[0042] (1) random copolymer p(BMA m -co-FMA n -co-AMA r ) preparation:

[0043] Dissolve 26.3g dimethyl propyl sulfonate aminoethyl methacrylate, 4.4g hexafluorobutyl methacrylate, 0.7g allyl methacrylate, 0.028g azodicyanovaleric acid in 47g trifluoro in ethanol. The above reactant was placed in a Schlenk tube and sealed, and after three freeze-thaw cycles, it was heated in an oil bath at 68°C for 10 h for free radical polymerization to obtain p(SBMA m -co-FMA n -co-AMA r ), wherein m:n:r=90:8:1, its structural formula is:

[0044]

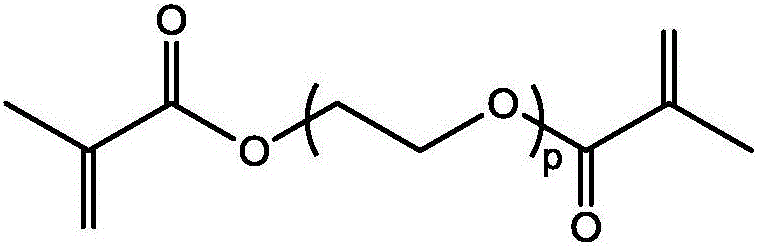

[0045] (2) Preparation of betaine zwitterionic polymer anti-fog coating:

[0046] 5g of the prepared random copolymer, 0.25g of polyethylene dimethacrylate (the number of repeating units is 4) and 0.1g of photoinitiator IRGACURE 2959 were dissolved in 80mL of trifluoroethanol, and ultrasonic vibration made the solution transparent Take 0.3mL solution and spin-coat (rotating speed: 600rpm for 10s, then 3000rpm for 15s) on the surface of...

Embodiment 2

[0049] (1) random copolymer p(BMA m -co-FMA n -co-AMA r ) preparation:

[0050] Dissolve 24.6g dimethyl butylsulfonate aminoethyl methacrylate, 13.3g dodecafluoroheptyl methacrylate, 3.5g allyl methacrylate, 0.028g azobiscyanovaleric acid in 62g tris in fluoroethanol. The above reactant was placed in a Schlenk tube and sealed, and after three freeze-thaw cycles, it was heated in an oil bath at 65°C for 11 h for free radical polymerization to obtain p(SBMA m -co-FMA n -co-AMA r ), wherein m:n:r=80:15:5, its structural formula is:

[0051]

[0052] (2) Preparation of betaine zwitterionic polymer anti-fog coating:

[0053] Dissolve 40g of the prepared random copolymer and 1g of photoinitiator IRGACURE 184 in 75mL of ethanol, and ultrasonically shake the solution to make the solution transparent; take 0.2mL of the solution and spin coat (rotate at 600rpm for 10s, then 3000rpm for 15s) at 2.5cm× The surface of the 7.0cm glass substrate was surface-dry at room temperature...

Embodiment 3

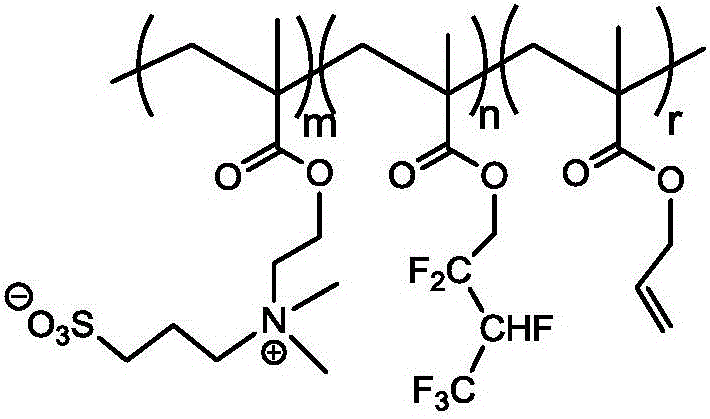

[0056] (1) random copolymer p(BMA m -co-FMA n -co-AMA r ) preparation:

[0057] 20.4g 3-[2-(methacryloxy)ethyl] dimethyl ammonium propionate, 9.5g trifluorooctyl methacrylate, 3.5g allyl methacrylate, 0.028g azo Dicyanovaleric acid was dissolved in 50 g of trifluoroethanol. The above reactant was placed in a Schlenk tube and sealed, and after three freeze-thaw cycles, it was heated in an oil bath at 70°C for 10 h for free radical polymerization to obtain p(CBMA m -co-FMA n -co-AMA r ), wherein m:n:r=85:10:5, its structural formula is:

[0058]

[0059] (2) Preparation of betaine zwitterionic polymer anti-fog coating:

[0060] Dissolve 30g of the prepared random copolymer, 3g of ethylene glycol dimethacrylate and 0.75g of photoinitiator DAROCUR1173 in 84mL of methanol, and ultrasonically vibrate to make the solution transparent; take 0.4mL of the solution and spray it on a surface of 2.5cm×7.0cm The surface of the glass substrate was surface-dried at room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com