Preparation method of hydrogel with high self-repairing capacity and high electric conductivity

A technology of self-healing and conductivity, applied in the field of hydrogel, can solve the problems of long time-consuming polymerization method, etc., and achieve the effect of excellent mechanical properties, high ionic conductivity, and strong self-healing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a hydrogel with strong self-repair ability and high conductivity, comprising the following steps:

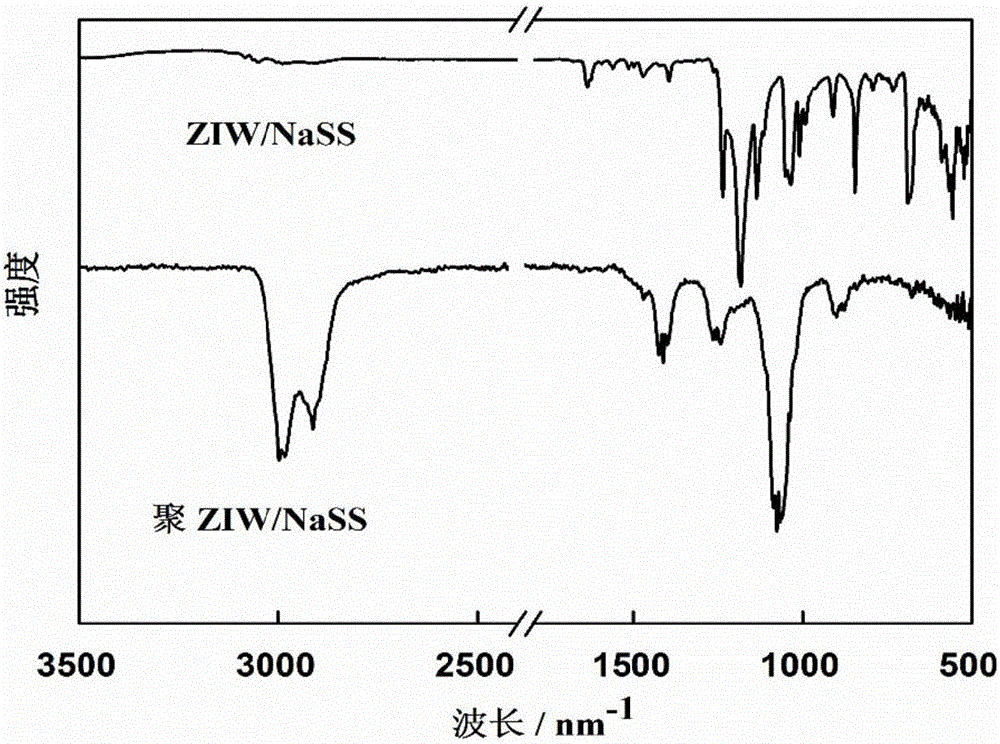

[0037] (1) Synthesis of 3‐(4‐vinyl‐1‐pyridine)propanesulfonate (ZIW)

[0038] Dissolve 6.31g of 4-vinylpyridine in an appropriate amount of acetone solution, then dissolve 7.33g of 1,3-propane sultone in an appropriate amount of acetone and slowly add it dropwise to 4-ethylene at 0°C under nitrogen protection base pyridine in acetone solution; after the dropwise addition, stirred and reacted at 25°C for 5 days; after the reaction was complete, filtered, and the filter cake was washed 3 times with acetone; then vacuum-dried to obtain 3‐(4‐vinyl‐1‐pyridine ) propanesulfonate. The 3‐(4‐vinyl‐1‐pyridine)propanesulfonate (ZIW) is a white solid belonging to an amphoteric salt, with 1HNMR (400M, D 2 O) for purity characterization.

[0039] (2) Synthesis of hydrogel

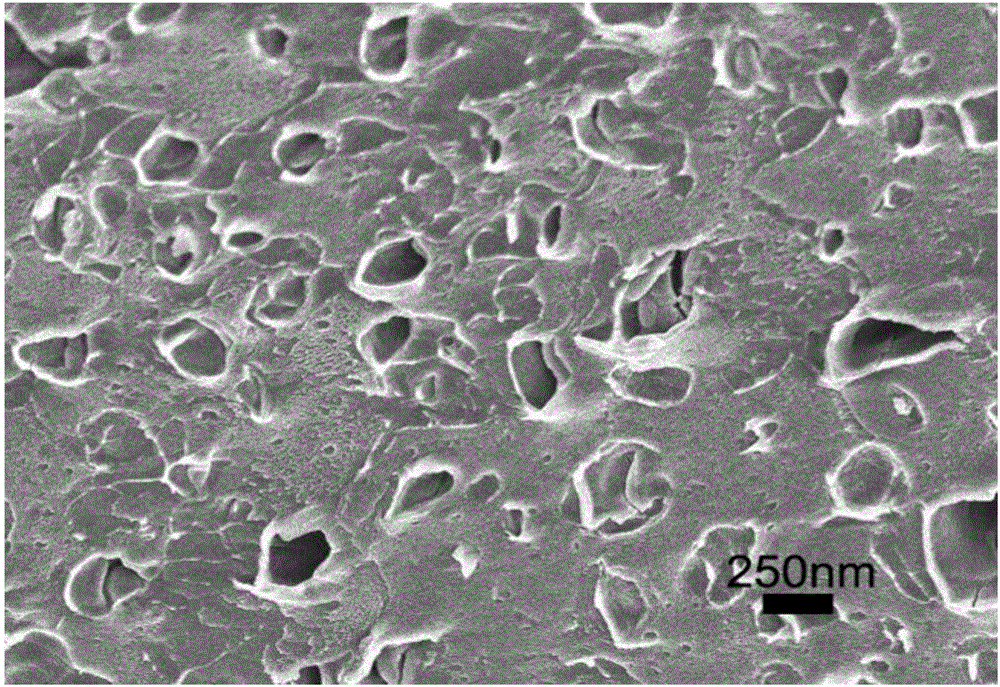

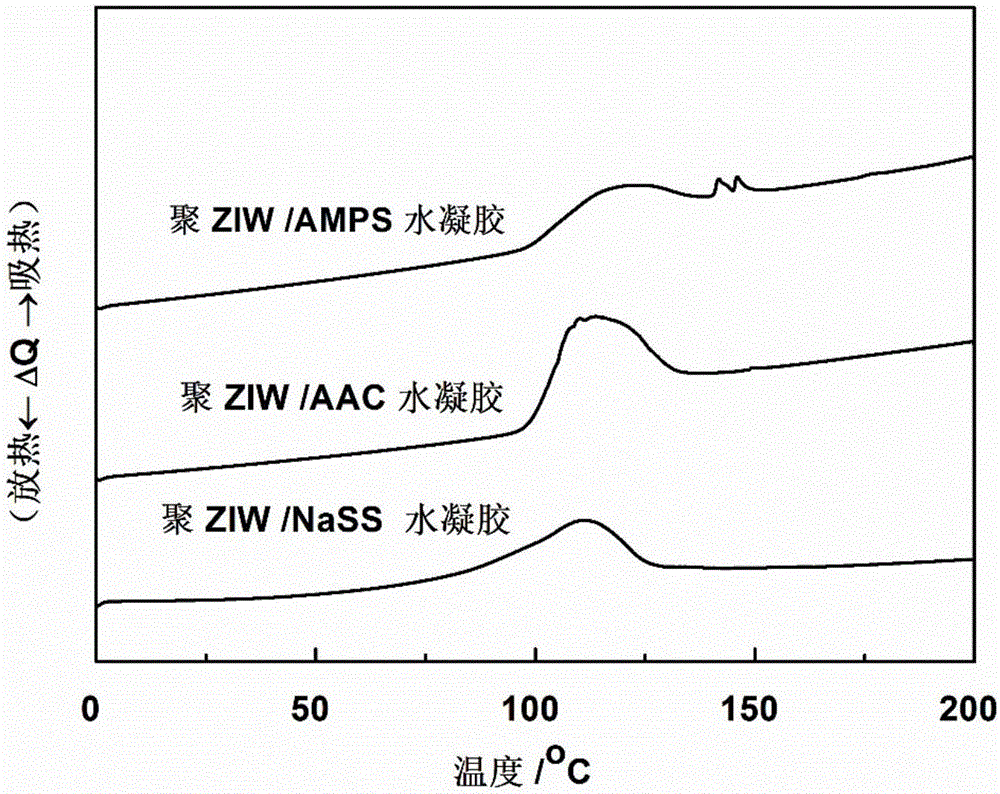

[0040]Dissolve 0.45g 3‐(4‐vinyl‐1‐pyridine)propanesulfonate (ZIW) and 0.41g sodium p-s...

Embodiment 2

[0042] A method for preparing a hydrogel with strong self-repair ability and high conductivity, comprising the following steps:

[0043] Same as (1) in Example 1,

[0044] (2) Synthesis of hydrogel

[0045] Dissolve 0.45g 3‐(4‐vinyl‐1‐pyridine)propanesulfonate (ZIW) and 0.41g 2‐acrylamide‐2‐methylpropanesulfonic acid (AMPS) in 0.5mL water, then add 0.0031g crosslinker Agent N,N‐methylenebisacrylamide (MBAA) and 0.017g photoinitiator 1173 were used to initiate polymerization under 365nm wavelength ultraviolet light irradiation for 1h to obtain a hydrogel. The hydrogel is a polyionic liquid hydrogel.

Embodiment 3

[0047] A method for preparing a hydrogel with strong self-repair ability and high conductivity, comprising the following steps:

[0048] Same as (1) in Example 1,

[0049] (2) Synthesis of hydrogel

[0050] Dissolve 0.45g of 3‐(4‐vinyl‐1‐pyridine)propanesulfonate (ZIW) and 0.14g of acrylic acid (AAC) in 0.5mL of water, then add 0.0031g of crosslinker N,N‐methylenebispropene Amide (MBAA) and 0.012g photoinitiator 1173 were irradiated with 365nm wavelength ultraviolet light to initiate polymerization for 1h to obtain a hydrogel. The hydrogel is a polyionic liquid hydrogel.

[0051] Example 4-6

[0052] The preparation method of the hydrogel with strong self-healing ability and high conductivity as shown in Example 1, the difference is:

[0053] In step (2), the addition amount of cross-linking agent N, N-methylenebisacrylamide (MBAA) is 0.0015g, 0.0046g, 0.0062g (that is, the addition amount of cross-linking agent is 3-(4-vinyl 0.5mol%, 1.5mol%, 2mol% of ‐1‐pyridine) propan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com