Preparation method of modified PPTA with fluorescent effect

A kind of effect and modification technology, applied in the field of preparation of modified PPTA, can solve the problems of being only soluble in concentrated sulfuric acid, difficult processing, high equipment requirements, etc., achieve good application prospects and improve solubility performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

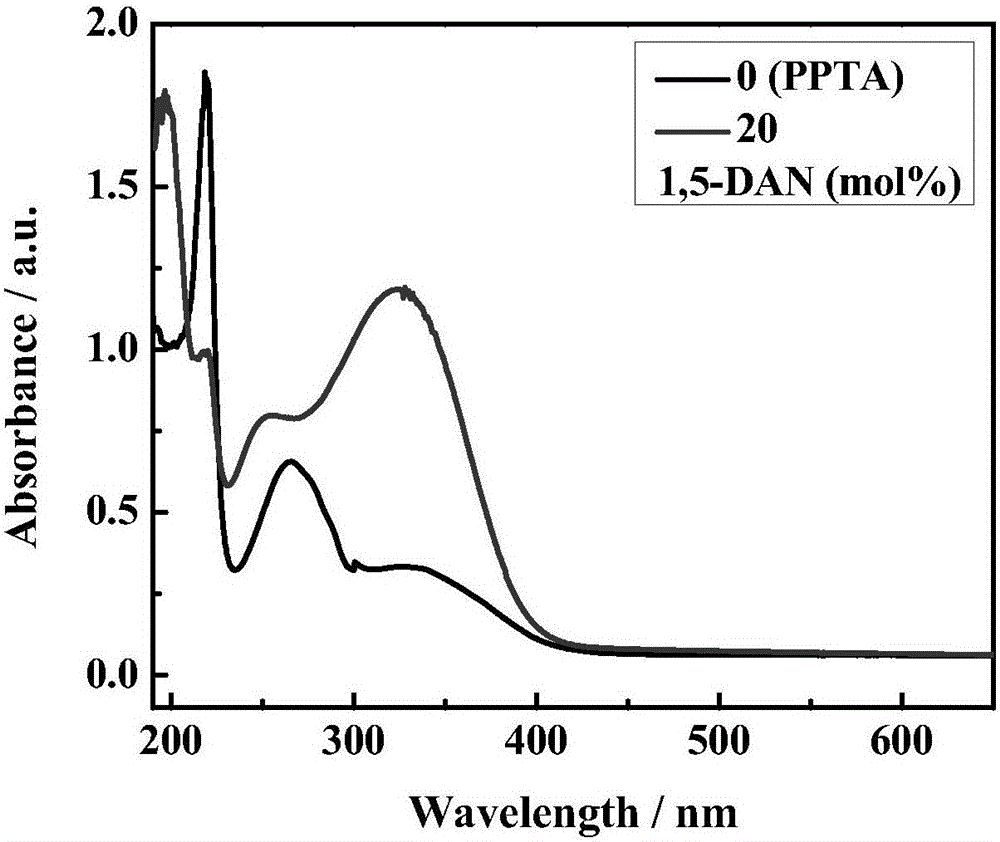

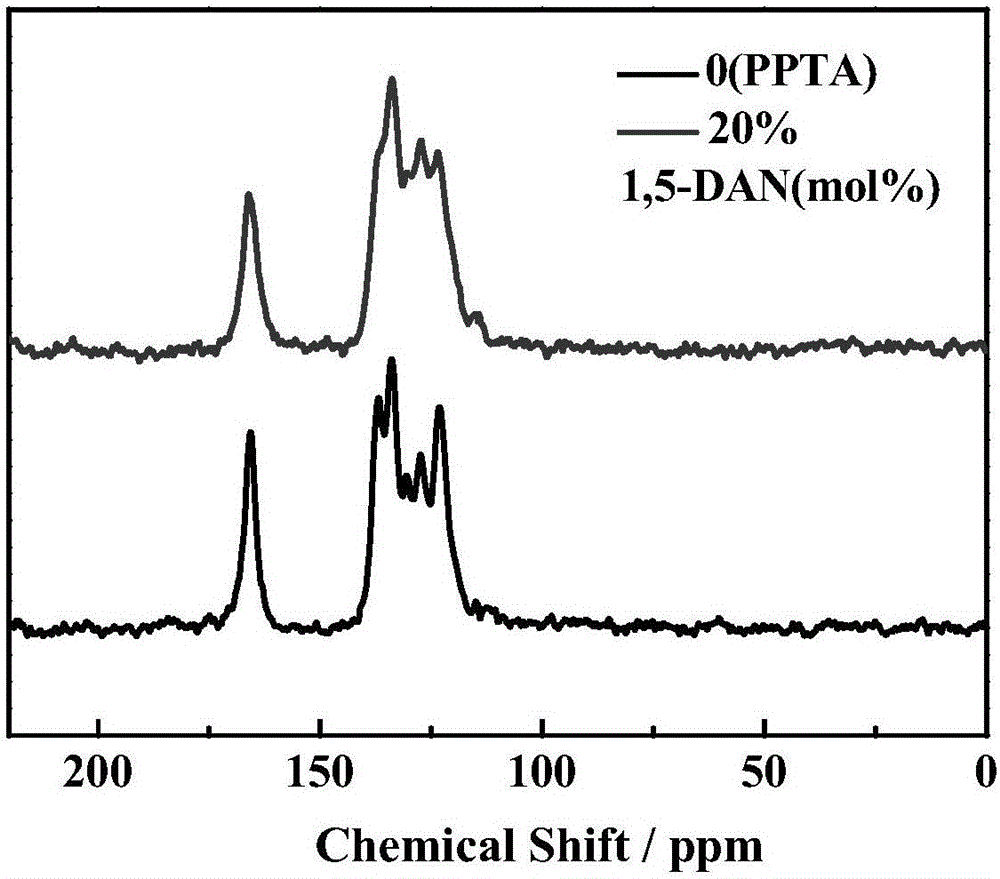

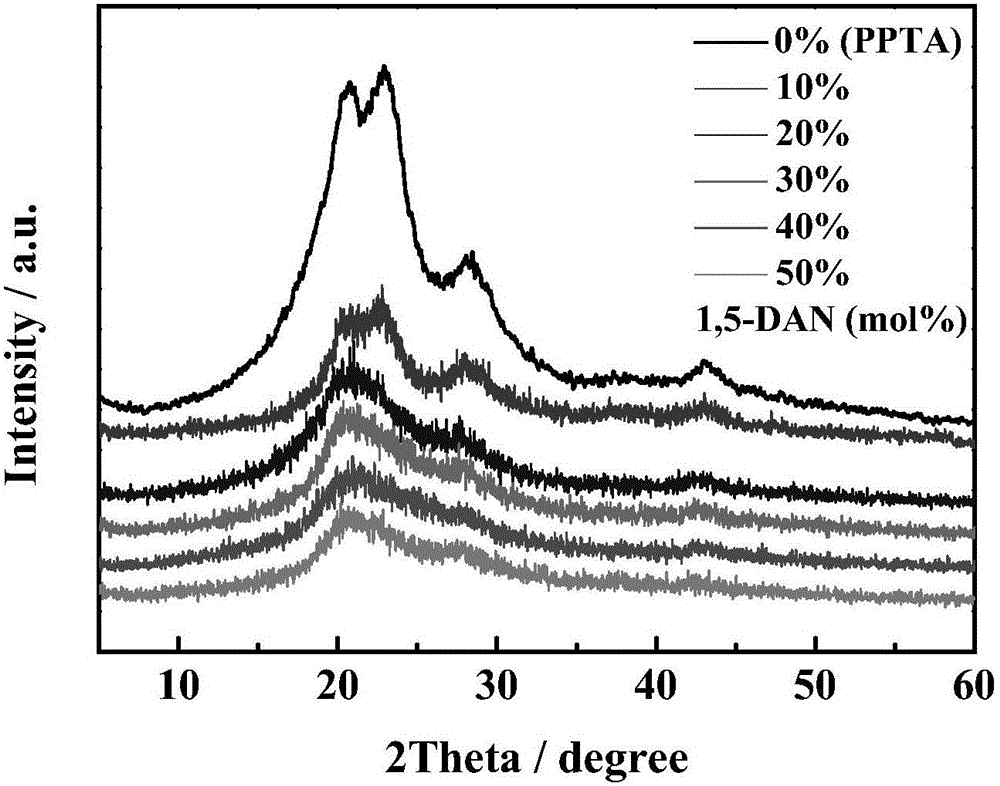

[0031] Under nitrogen protection conditions, add 57mL of N-methylpyrrolidone (NMP) and 0.912g of LiCl to the three-necked flask, mechanically stir and dissolve at room temperature, and make a LiCl / NMP solution with a mass concentration of 16g / L; After dissolving, add 1.944g of powdered p-phenylenediamine (PDA) and 0.316g of 1,5-naphthalene diamine under stirring condition, until they are completely dissolved, cool to -10°C with a constant temperature condensing ethanol bath, and divide Add terephthaloyl chloride (TPC) twice, half of the total amount is added each time, and the added amount is 4.06406g in total. Immediately increase the speed to 500-3000r / min, and immediately add 1.5mL of acid absorbent pyridine (the concentration of pyridine is 26ml / L), remove the constant temperature condensing ethanol bath after the rod climbing phenomenon occurs after 30 minutes of reaction, and continue to react for two hours at room temperature. After standing still, filter with suction, ...

Embodiment 2

[0033] Under nitrogen protection conditions, add 57mL of N-methylpyrrolidone (NMP) and 0.912g of LiCl to the three-necked flask, mechanically stir and dissolve at room temperature, and make a LiCl / NMP solution with a mass concentration of 16g / L; After dissolving, add 1.728g of powdered p-phenylenediamine (PDA) and 0.632g of 1,5-naphthalenediamine under stirring condition, until they are completely dissolved, cool to -10°C with a constant temperature condensing ethanol bath, and divide Add terephthaloyl chloride (TPC) twice, the total amount added is 4.06406g, immediately increase the speed to 500-3000r / min, immediately add 1.5mL of acid absorbent pyridine (concentration of pyridine is 26ml / L), and react for 30min. After the rod climbing phenomenon, the constant temperature condensing ethanol bath was removed, and the reaction was continued for two hours at room temperature. After standing still, filter with suction, wash the precipitate with water and ethanol several times unt...

Embodiment 3

[0035] Under nitrogen protection conditions, add 57mL of N-methylpyrrolidone (NMP) and 0.912g of LiCl to the three-necked flask, mechanically stir and dissolve at room temperature, and make a LiCl / NMP solution with a mass concentration of 16g / L; After dissolving, add 1.512g of powdered p-phenylenediamine (PDA) and 0.948g of 1,5-naphthalene diamine under stirring condition, until they are completely dissolved, cool to -10°C with a constant temperature condensing ethanol bath, and divide Add terephthaloyl chloride (TPC) twice, the total amount added is 4.06406g, immediately increase the speed to 500-3000r / min, immediately add 1.5mL of acid absorbent pyridine (concentration of pyridine is 26ml / L), and react for 30min. After the rod climbing phenomenon, the constant temperature condensing ethanol bath was removed, and the reaction was continued for two hours at room temperature. After standing still, filter with suction, wash the precipitate with water and ethanol several times un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com