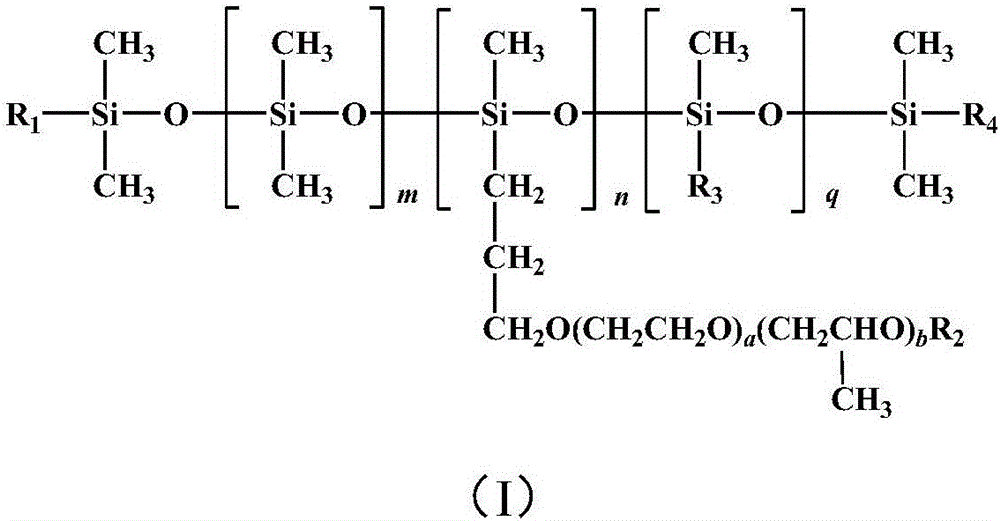

Mercapto nano-silica and polyether dual modified organosilicon surfactant and preparation method

A nano-silica, surfactant technology, applied in chemical instruments and methods, transportation and packaging, chemical/physical processes, etc., can solve the problem of uneven dispersion of nano-modified materials, poor compatibility, and single polysiloxane. and other problems, to achieve good hydrophilic and lipophilic and compatible properties, strong chemical stability, and broaden the application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

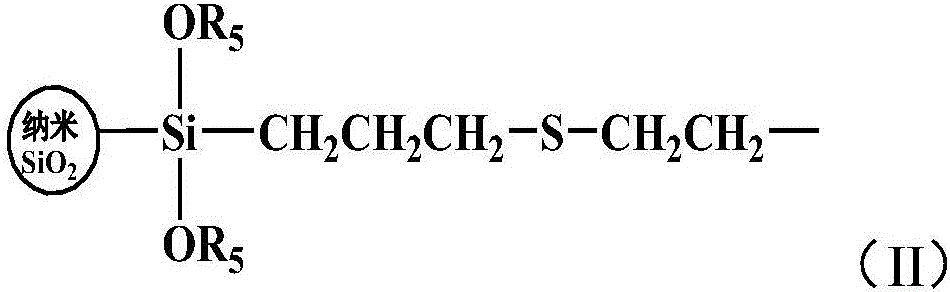

[0044] (1) Preparation of mercapto nano-silica

[0045] Weigh 30.63g of nano-silica and ultrasonically disperse it in anhydrous ethanol solution at 40°C, and add 6.12g of 3-mercaptopropyltrimethoxysilane dropwise to the above-mentioned silica solution, using ammonia as a catalyst to adjust the reaction Environment to pH=8.9, react at 80° C. for 8 hours, wash with absolute ethanol, and dry to obtain mercapto-functionalized nano-silica.

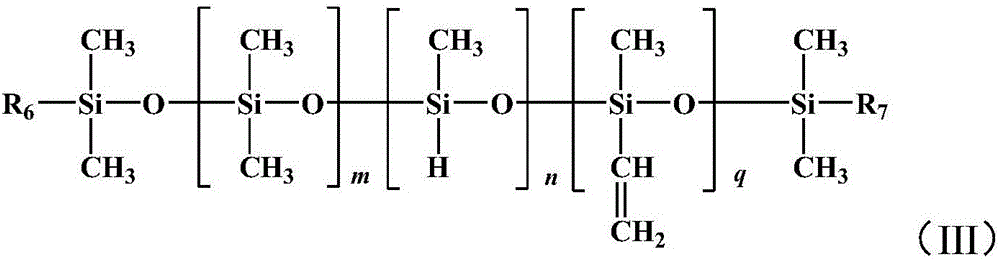

[0046] (2) Preparation of vinyl polymethylhydrogen siloxane

[0047] Weigh 41.53g of octamethylcyclotetrasiloxane, 12.63g of 1,3,5,7-tetramethylcyclotetrasiloxane, 6.02g of tetravinyltetramethylcyclotetraoxane and 2.27g of hexamethylbis Add 0.94 g of concentrated sulfuric acid as a reaction catalyst to the siloxane in the reactor, and keep the reaction at 45° C. for 6 hours to obtain vinyl-containing polymethylhydrogen siloxane.

[0048] (3) Preparation of polymethylhydrogensiloxane modified by mercapto nano-silica

[0049] Take by weighing ...

Embodiment 2

[0053] (1) Preparation of mercapto nano-silica

[0054] Weigh 136.55g of nano-silica and ultrasonically disperse it in anhydrous methanol solution at 30°C, and add 32.3g of 3-mercaptopropyltriethoxysilane dropwise to the above-mentioned silica solution, using ammonia as a catalyst, adjust The reaction environment was adjusted to pH=9.2, reacted at 80° C. for 6 h, washed with absolute ethanol, and dried to obtain mercapto-functionalized nano-silica.

[0055] (2) Preparation of vinyl polymethylhydrogen siloxane

[0056] Weigh 206.45g octamethylcyclotetrasiloxane, 15.69g1,3,5,7-tetramethylcyclotetrasiloxane and 16.22g tetramethyldivinyldisiloxane in the reactor, add 11.92 g concentrated sulfuric acid was used as the reaction catalyst, and the reaction was carried out at 55° C. for 3 hours to obtain vinyl-containing polymethylhydrogen siloxane.

[0057] (3) Preparation of polymethylhydrogensiloxane modified by mercapto nano-silica

[0058] Take by weighing 103.69g step (1) merc...

Embodiment 3

[0062] (1) Preparation of mercapto nano-silica

[0063] Weigh 75.39g of nano silicon dioxide and ultrasonically disperse it in anhydrous ethanol solution at 20°C, and add 18.1g of 3-mercaptopropyltriethoxysilane dropwise to the above silicon dioxide solution, using ammonia water as a catalyst, adjust The reaction environment was adjusted to pH=8.5, reacted at 70° C. for 10 h, washed with absolute ethanol, and dried to obtain mercapto-functionalized nano-silica.

[0064] (2) Preparation of vinyl polymethylhydrogen siloxane

[0065] Weigh 206.45g of octamethylcyclotetrasiloxane, 15.69g of 1,3,5,7-tetramethylcyclotetrasiloxane, 24.82g of tetravinyltetramethylcyclotetraoxane and 17.89g of tetramethylbis Add 8.34 g of trifluoromethanesulfonic acid to the reactor with vinyl disiloxane as a reaction catalyst, and keep the reaction at 80° C. for 4.5 hours to obtain vinyl-containing polymethylhydrogen siloxane.

[0066] (3) Preparation of polymethylhydrogensiloxane modified by mercap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com