Method for preparing hyperbranched polymer through dual click chemistry

A technology of hyperbranched polymers and click chemistry, which is applied in the field of synthesis of hyperbranched polymers, can solve the problems of hyperbranched polymers that need to be expanded, monomers that cannot be purchased commercially, and chemical reactions that are limited, so as to achieve a wide range of applicable monomers , high repeatability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

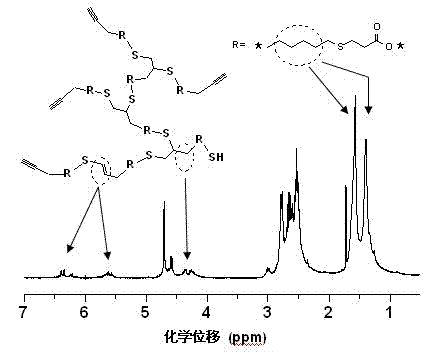

[0020] Step 1), under nitrogen protection, hexanedithiol (3.01 g, 20 mmol), ethyl acetate (17.62 g, 200 mmol), triethylamine (1.01 g, 10 mmol), propylene acrylate were added successively in the reactor Alkyne ester (2.20 g, 20 mmol), at 30 o C for 5 hours, evaporated under reduced pressure to remove ethyl acetate and triethylamine;

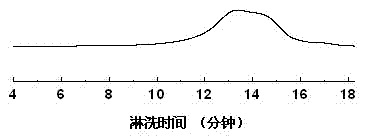

[0021] Step 2), under nitrogen protection, the product obtained in step 1) was dissolved in 20 mL of toluene, and 4 mol% of thermosensitive free radical initiator azobisisobutyronitrile (131.3 mg) was added, at 65 o C polymerization reaction 3 hours, obtain hyperbranched polymer (number average molecular weight is 7200; weight average molecular weight is 104800; degree of branching 0.76) through methanol precipitation, separation, drying.

Embodiment 2

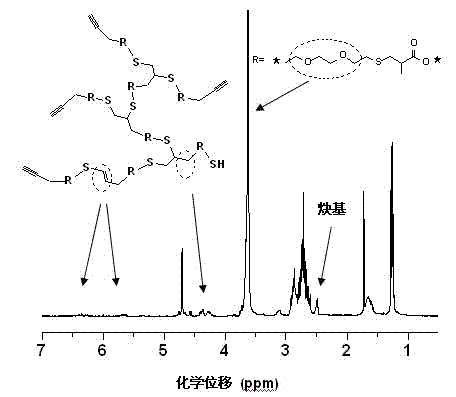

[0023] Step 1), under nitrogen protection, hexanedithiol (3.01 g, 20 mmol), ethyl acetate (17.62 g, 200 mmol), triethylamine (4.04 g, 40 mmol), propylene acrylate were added successively in the reactor Alkyne ester (2.20 g, 20 mmol), at 10 o C for 5 hours, evaporated under reduced pressure to remove ethyl acetate and triethylamine;

[0024] Step 2), under nitrogen protection, the product obtained in step 1) was dissolved in 20 mL of toluene, and 4 mol% of thermosensitive free radical initiator azobisisobutyronitrile (131.3 mg) was added, at 65 o C polymerized for 3 hours, precipitated with methanol, separated and dried to obtain a hyperbranched polymer.

Embodiment 3

[0026] Step 1), under nitrogen protection, add hexanedithiol (3.01 g, 20 mmol), ethyl acetate (0.17 g, 2 mmol), triethylamine (1.23 g, 22 mmol), propylene acrylate in the reactor successively Alkyne ester (2.20 g, 20 mmol), at 40 o C for 0.5 hours, evaporated under reduced pressure to remove ethyl acetate and triethylamine;

[0027] Step 2), under nitrogen protection, the product obtained in step 1) was dissolved in 20 mL of toluene, and 4 mol% of thermosensitive free radical initiator azobisisobutyronitrile (131.3 mg) was added, at 65 o C polymerized for 3 hours, precipitated with methanol, separated and dried to obtain a hyperbranched polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com