High-toughness and halogen-free flame retardant polypropylene cable material and preparation method thereof

A flame-retardant polypropylene, high-toughness technology, used in plastic/resin/wax insulators, organic insulators, etc., can solve the problems of poor toughness and poor flame retardancy of polypropylene cable materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

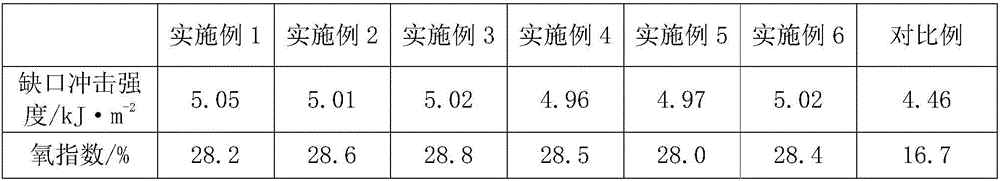

Examples

Embodiment 1

[0026] High-toughness, halogen-free flame-retardant polypropylene cable compound, made of the following components by weight: 100 parts of isotactic polypropylene, 0.5 parts of a mixture of antioxidant 1010 and antioxidant 1068, 1.5 parts of calcium stearate, 0.6 parts of UV-531, 11 parts of TOTM, 4.2 parts of maleic anhydride grafted polypropylene, 0.4 parts of talcum powder, 6 parts of POE, and 12 parts of modified dickite powder.

[0027] The steps of its preparation method include:

[0028] (1) Dickite is put into the barrel of the planetary ball mill, add the ceramic grinding balls with a diameter of 5mm, dehydrated alcohol and cover the cylinder cover, the weight ratio of dickite, ceramic grinding balls and dehydrated alcohol is 4 :1:0.2, turn on the ball mill, ball mill at a speed of 250rpm for 3 hours, take it out, vacuum filter, rinse with deionized water for 5 minutes, then dry at 90°C, vibrate and sieve with a vibrating grading sieve for 30 minutes to obtain dickite...

Embodiment 2

[0033] High-toughness, halogen-free flame-retardant polypropylene cable compound, made of the following components by weight: 100 parts of isotactic polypropylene, 0.7 parts of a mixture of antioxidant 1010 and antioxidant 1068, 1.3 parts of calcium stearate, 0.4 parts of UV-531, 13 parts of TOTM, 4 parts of maleic anhydride grafted polypropylene, 0.6 parts of talc powder, 8 parts of POE, and 14 parts of modified dickite powder.

[0034] Its preparation method is the same as Example 1.

Embodiment 3

[0036] High-toughness, halogen-free flame-retardant polypropylene cable compound, made of the following components by weight: 100 parts of isotactic polypropylene, 0.9 parts of a mixture of antioxidant 1010 and antioxidant 1068, 1.1 parts of calcium stearate, 0.2 parts of UV-531, 15 parts of TOTM, 4.4 parts of maleic anhydride grafted polypropylene, 0.2 parts of talcum powder, 10 parts of POE, and 16 parts of modified dickite powder.

[0037] Its preparation method is the same as Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com