Polyvinyl alcohol membrane with self-repair function implemented by aid of dynamic covalent bonds and method for preparing polyvinyl alcohol membrane

A polyvinyl alcohol film and polyvinyl alcohol technology, applied in the field of functional materials, can solve the problems of easy mechanical failure, damage, poor water resistance, etc., and achieve the effects of reducing maintenance, prolonging service life, and good water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

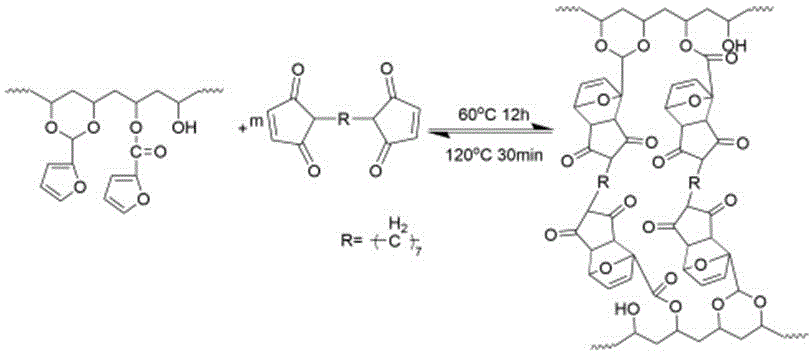

[0040] Preparation of self-healing polyvinyl alcohol membranes by using Diels-Alder reaction to construct dynamic covalent bonds:

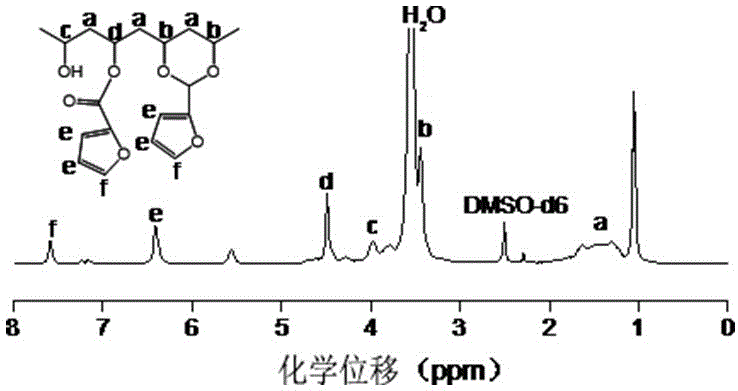

[0041] (1) Mix 11g of polyvinyl alcohol with 200mL of DMSO, stir at 70°C~80°C until the solution becomes transparent; then add 2g of p-toluenesulfonic acid and stir to dissolve evenly, then add 20mL of furfural, stir at 70°C~80°C for 12 hours, Precipitate the product with ethanol and extract it for 5 hours, then dry it to obtain the product, that is, obtain furan ring graft-modified polyvinyl alcohol;

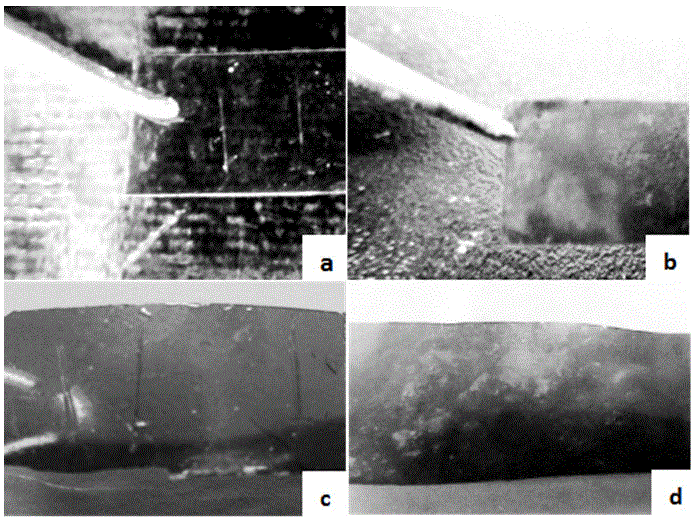

[0042] (2) Take 0.7g of the graft-modified polyvinyl alcohol obtained in (1), dissolve it in 30mL of DMSO at 70~80°C, cool to room temperature, add 0.2g of N,N'-hexamethylenebisma imide, stirred until uniform, to obtain a modified PVA film liquid with self-healing properties. Scrape-coat the obtained film solution on a polytetrafluoroethylene film frame with a size of 10cm*10cm, place it in an oven at 60°C for 12 hours, and after the solvent is dr...

Embodiment 2

[0046] Preparation of polyvinyl alcohol film with high grafting degree and dynamic covalent bond self-healing:

[0047] (1) Mix 11g of polyvinyl alcohol with 200ml of DMSO, stir at 70°C~80°C until the solution becomes transparent; then add 2g of p-toluenesulfonic acid and stir to dissolve evenly, then add 20ml of furfural, stir at 70°C~80°C for 12 hours, The product was precipitated with ethanol and extracted for 5 hours, then dried to obtain the product of the first step. Take 2g of the product of the first step and dissolve it in 100ml of DMSO at 70~80°C, add 3ml of furoyl chloride dropwise in an ice-water bath for 30 minutes, react at room temperature for 4 hours, precipitate with deionized water, wash and dry to obtain the product of the second step, that is, the novel Graft-modified polyvinyl alcohol;

[0048] (2) Take 0.7g of the graft-modified polyvinyl alcohol obtained in (1), dissolve it in 30ml of DMSO at 70~80°C, cool to room temperature, add 0.2g of N,N'-hexamethy...

Embodiment 3

[0053] Preparation of dynamic covalent bond self-healing polyvinyl alcohol film:

[0054] (1) Mix 11g of polyvinyl alcohol with 200mL of DMSO, stir at 70°C~80°C until the solution becomes transparent; then add 2g of p-toluenesulfonic acid and stir to dissolve evenly, then add 20mL of furfural, stir at 70°C~80°C for 12 hours, The product was precipitated with ethanol and extracted for 5 hours, then dried to obtain the product of the first step;

[0055] (2) Take 2g of the product from the first step and dissolve it in 100mL DMSO at 70-80°C, add 0.5g of divinylbenzene, stir until uniform, and obtain a modified PVA membrane liquid with self-healing properties. The obtained film solution was scraped onto a polytetrafluoroethylene film frame with a size of 10cm*10cm, and placed in an oven at 60°C for 12 hours. After the solvent was dried, a modified polyvinyl alcohol pervaporation film with self-healing ability was obtained.

[0056] The restoration effect test is similar to Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com