Epoxy cured high-flexibility polyester resin used for powdery paint and a preparing method thereof

A polyester resin and powder coating technology, applied in powder coatings, epoxy resin coatings, polyester coatings, etc., can solve the problems of polyester resin storage stability, cracking, falling off, etc., and achieve excellent impact resistance and folding Bending ability, increased athletic ability, sufficient time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

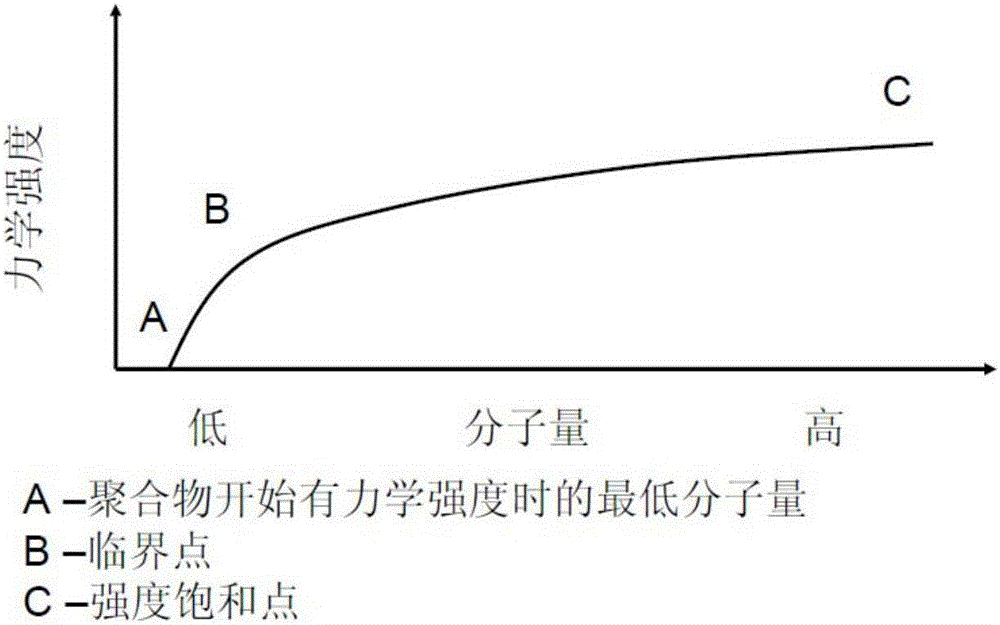

Problems solved by technology

Method used

Image

Examples

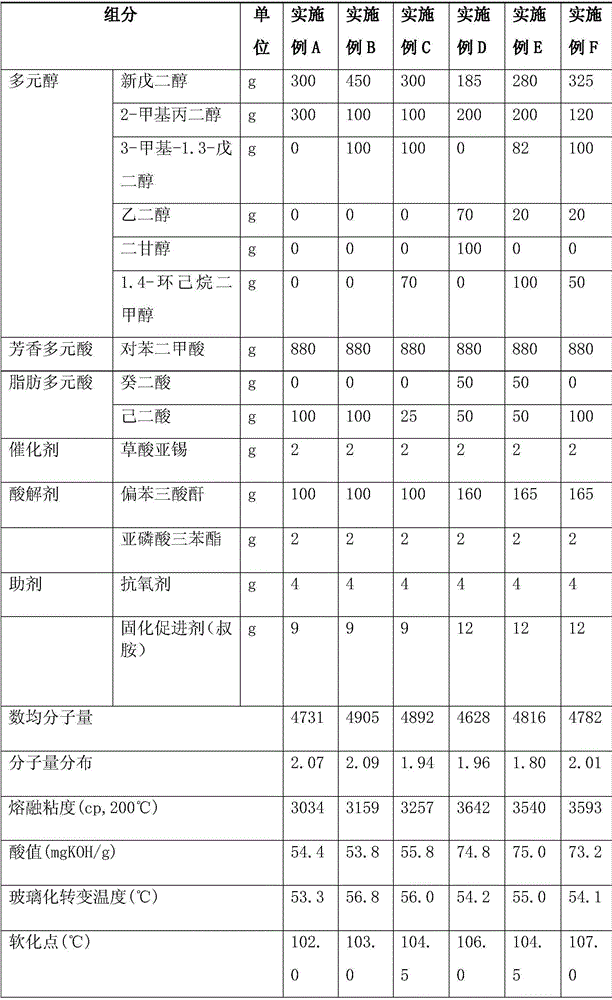

Embodiment A

[0041] Embodiment A.B.C process is: the preparation method of epoxy curing high flexibility powder coating polyester resin (the prepared polyester resin and epoxy resin prepare coating with the weight ratio of 60:40), carry out as follows:

[0042] 1) Add neopentyl glycol, 2-methylpropanediol, 3-methyl-1.5-pentanediol, and triphenyl phosphite to a reaction kettle equipped with a heating device, an agitator, and a distillation column, and raise the temperature under normal pressure To 110-130°C, then put in terephthalic acid, adipic acid and catalyst; while stirring, heat up at a rate of 2-3°C per minute;

[0043] 2) When the temperature of the material rises to 170-180°C, esterification water begins to be generated and evaporated through the distillation column; at this time, the heating rate is adjusted to 2-3°C every 30 minutes; when the temperature of the material rises to 195°C±2°C, the Control the temperature rise rate at 5-6°C every 30 minutes. When the temperature of th...

Embodiment E

[0047] Embodiment E.F.G process is: the preparation method of epoxy curing high flexibility powder coating polyester resin (the prepared polyester resin and epoxy resin prepare coating with the weight ratio of 50:50), carry out as follows:

[0048] 1) Add neopentyl glycol, 2-methylpropanediol, and 3-methyl-1.5-pentanediol into a reaction kettle equipped with a heating device, agitator and a distillation column, and raise the temperature to 110-130°C under normal pressure, Add terephthalic acid, adipic acid and catalyst; heat up at a rate of 2-3°C per minute while stirring;

[0049] 2) When the temperature of the material rises to 170-180°C, esterification water begins to be generated and evaporated through the distillation column; at this time, the heating rate is adjusted to 2-3°C every 30 minutes; when the temperature of the material rises to 195°C±2°C, the When the heating rate is adjusted to 5-6°C every 30 minutes, when the material temperature rises to 240°C±2°C, the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com