Comprehensive utilization technology of biomass resources

A biomass resource and process technology, applied in the patent application field of comprehensive utilization of biomass resources, can solve the problems of low utilization rate of raw materials and high energy consumption, improve the utilization rate of raw material carbon, reduce production and operation costs, The effect of high utilization of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

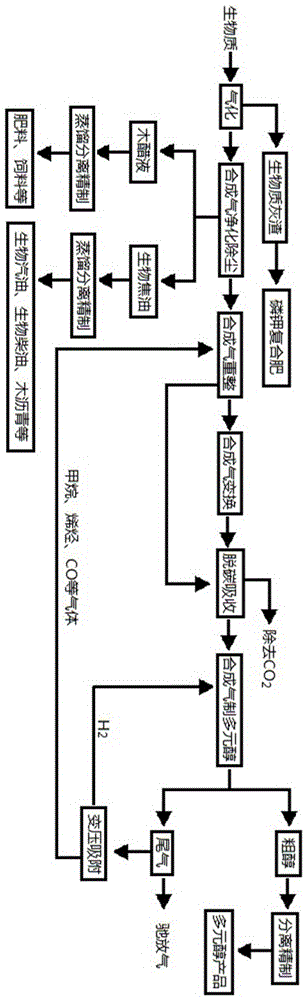

[0037] Such as figure 1 As shown, the comprehensive utilization process of biomass resources provided by this embodiment specifically includes the following steps.

[0038] (1) The raw materials of biomass resources (corn stalk shaped particles) are gasified in a fixed-bed gasifier, and the raw materials are pyrolyzed to produce crude synthesis gas;

[0039] In the process of preparing crude synthesis gas, the pyrolysis temperature of the gasifier: 470°C.

[0040] The measurement results show that the calorific value of the generated biomass synthesis gas is 15MJ / m 3 Above, after being converted into biomass synthesis gas, its energy conversion efficiency is about 75%, and the 25% energy lost is mainly contained in the high-temperature flue gas generated during the energy conversion process. Therefore, in order to reduce energy loss, the generated energy can be reduced The recovered high-temperature flue gas is used to dry and preheat the raw materials of biomass resources, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com