CeO2+MoS2 composite catalyzed high-capacity hydrogen storing alloy for fuel cell and preparation method of hydrogen storing alloy

A hydrogen storage alloy and fuel cell technology, applied in the field of hydrogen storage alloy materials, can solve the problems of difficulty in meeting the large-scale preparation of materials, inability to add catalysts, low efficiency of preparation materials, etc., so as to improve the thermodynamic and kinetic properties of hydrogen absorption and desorption, The effect of improving the stability of hydrogen absorption and desorption cycle, the thermodynamics and kinetics of hydrogen absorption and desorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

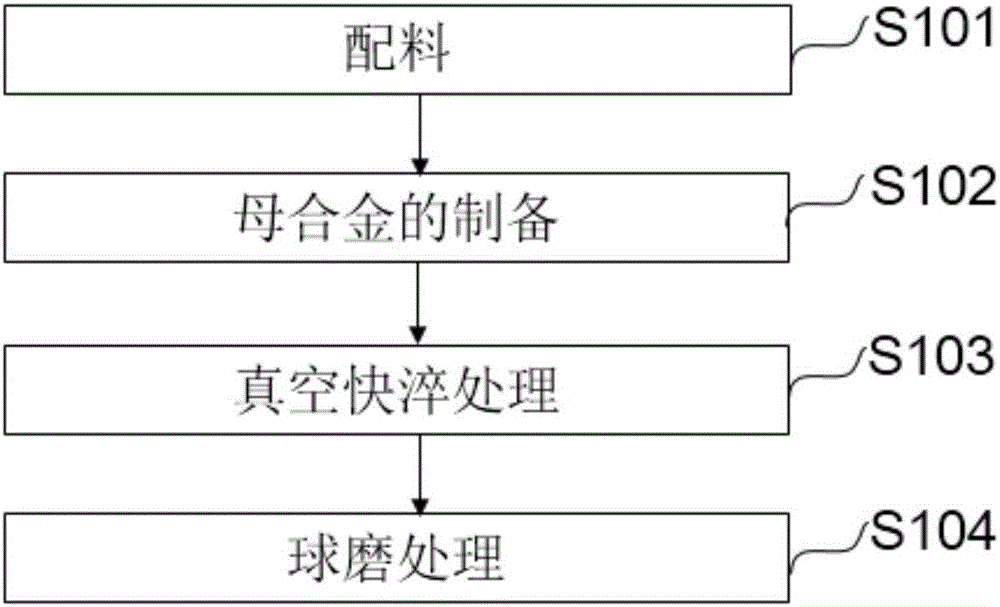

[0025] Such as figure 1 As shown, the CeO according to the present invention 2 +MoS 2A method for preparing a high-capacity hydrogen storage alloy for a composite catalytic fuel cell, comprising the steps of:

[0026] Ingredient S101: Composition Y according to chemical formula 1-x Ti x Mg 12-y-z Ni y Al z Perform batching, where 0.03≤x≤0.15, 0.3≤y≤1, 0.1≤z≤0.5. Wherein, the magnesium and rare earth elements in the composition of the chemical formula can increase the burning loss by 5%-10% when proportioned.

[0027] Preparation of master alloy S102: Put the above ingredients in the crucible, and put the magnesium on the top layer of the crucible, and then put it in a vacuum of 1×10 -2 ~5×10 -5 Under the condition of Pa, an inert gas of 0.01MPa~0.1MPa is introduced as a protective gas, then heated to 1400℃~1600℃, and kept for 1min~5min to obtain molten Y 1-x Ti x Mg 12-y-z Ni y Al z liquid master alloy, then the molten Y 1-x Ti x Mg 12-y-z Ni y Al z The liqu...

Embodiment 1

[0032] Embodiment 1 provides a kind of CeO 2 +MoS 2 A high-capacity hydrogen storage alloy for a composite catalytic fuel cell, comprising the following components: Y 1-x Ti x Mg 12-y-z Ni y Al z +m wt.%(CeO 2 +MoS 2 ), where x, y, z are atomic ratios, and m is CeO 2 +MoS 2 The mass percentage; Among them, CeO 2 with MoS 2 The mass ratio is 1:1, x=0.05, y=0.8, z=0.2, m=5, and its composition chemical formula is: Y 0.95 Ti 0.05 Mg 11 Ni 0.8 Al 0.2 +5wt.% (CeO 2 +MoS 2 ).

[0033] CeO in this example 2 +MoS 2 The method for preparing a high-capacity hydrogen storage alloy for a composite catalytic fuel cell comprises the following steps:

[0034] a. Ingredients: Composition Y according to chemical formula 0.95 Ti 0.05 Mg 11 Ni 0.8 Al 0.2 Carry out batching, select bulk rare earth metal yttrium, metal titanium, metal magnesium, metal nickel, metal and aluminum, weigh 436.3 grams of rare earth metal yttrium, metal titanium 11.8 grams, metal magnesium 1420....

Embodiment 2

[0039] The difference between embodiment 2 and embodiment 1 is only that the CeO provided by embodiment 2 2 +MoS 2 A high-capacity hydrogen storage alloy for a composite catalytic fuel cell, the chemical formula of which is: Y 0.95 Ti 0.05 Mg 11 Ni 0.8 Al 0.2 +3wt.% (CeO 2 +MoS 2 ).

[0040] CeO of Example 2 2 +MoS 2 In the method for preparing a high-capacity hydrogen storage alloy for a composite catalytic fuel cell, in the ball milling step, 50 g of sieved alloy powder and CeO 2 and MoS 2 0.75g each, put them together into a stainless steel ball mill jar, vacuumize and fill with high-purity argon, and then seal it. The rest of the steps are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com