Method for monitoring stress of composite material in all directions based on carbon nanotube film

A technology of carbon nanotube film and carbon nanotube film, which is applied in the field of preparation of carbon nanotube alignment film and its composite materials, and achieves the effects of wide application, increased effective length and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The invention provides a method for monitoring the isotropic strain of a composite material based on a carbon nanotube film, the preparation method comprising the following steps:

[0050] The first step is the preparation of random carbon nanotube films.

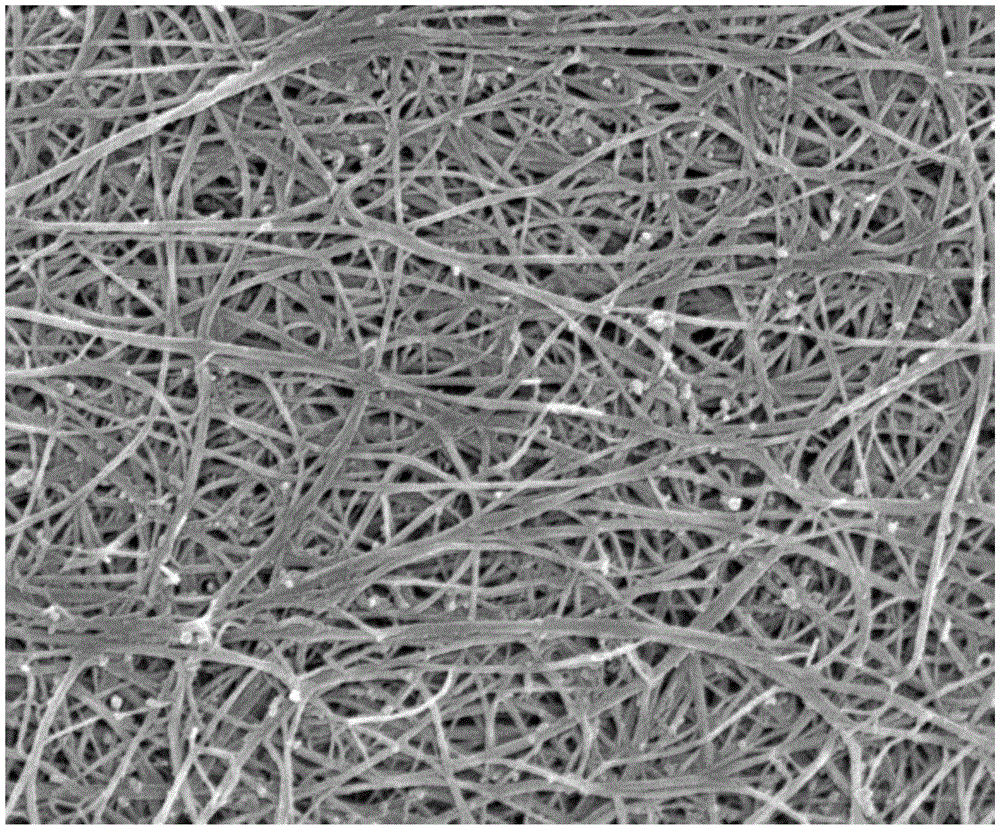

[0051] The film can be prepared by methods such as vapor deposition; the film is composed of tens to hundreds of thin layers of carbon nanotubes with a thickness not less than 0.1 μm. distributed along the thickness, see figure 1 . The preparation of the carbon nanotube film by the vapor deposition method comprises the following steps:

[0052] Under the protection of an inert gas (such as argon, hydrogen or a mixture of the two), inject the mixed system of carbon source ethanol, thiophene and catalyst ferrocene into a high-temperature tube furnace. At the other end of the high-temperature tube furnace, a winding device is used to collect the formed carbon nanotube airgel. The thickness of the single-layer airgel ...

Embodiment 1

[0067] Applying the preparation method provided by the present invention, by compounding the non-oriented carbon nanotube film / epoxy composite film with the glass fiber composite material, the glass fiber composite material capable of axial strain monitoring is prepared, and the specific steps are as follows:

[0068] The first step, the preparation of carbon nanotube film;

[0069] Under the protection of an inert gas, the mixture of ethanol, ferrocene and thiophene was injected into a high-temperature tube furnace at 1300° C. at a rate of 0.15 ml / min. The inert gas is a mixture of argon and hydrogen (volume ratio 1:1), and its flow rate is 4000 sccm. Continuous carbon nanotube airgel is formed at the other end of the high-temperature tube furnace, and the carbon nanotube airgel is collected by a winding device. The width of the drum is 3cm, the diameter is 0.5m, and the thickness of the single layer of carbon nanotube airgel is about 0.1μm. At the same time, the carbon nano...

Embodiment 2

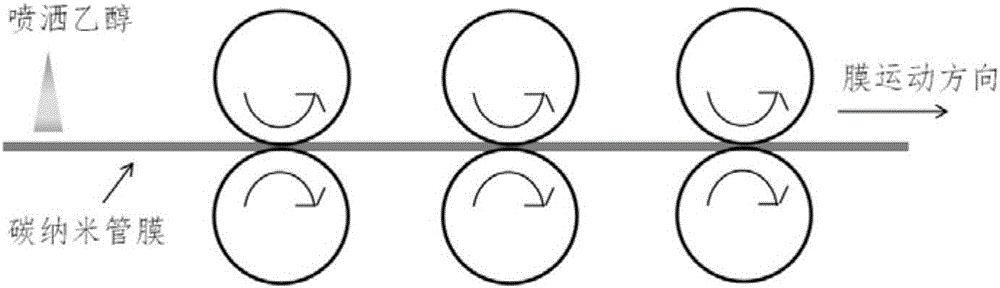

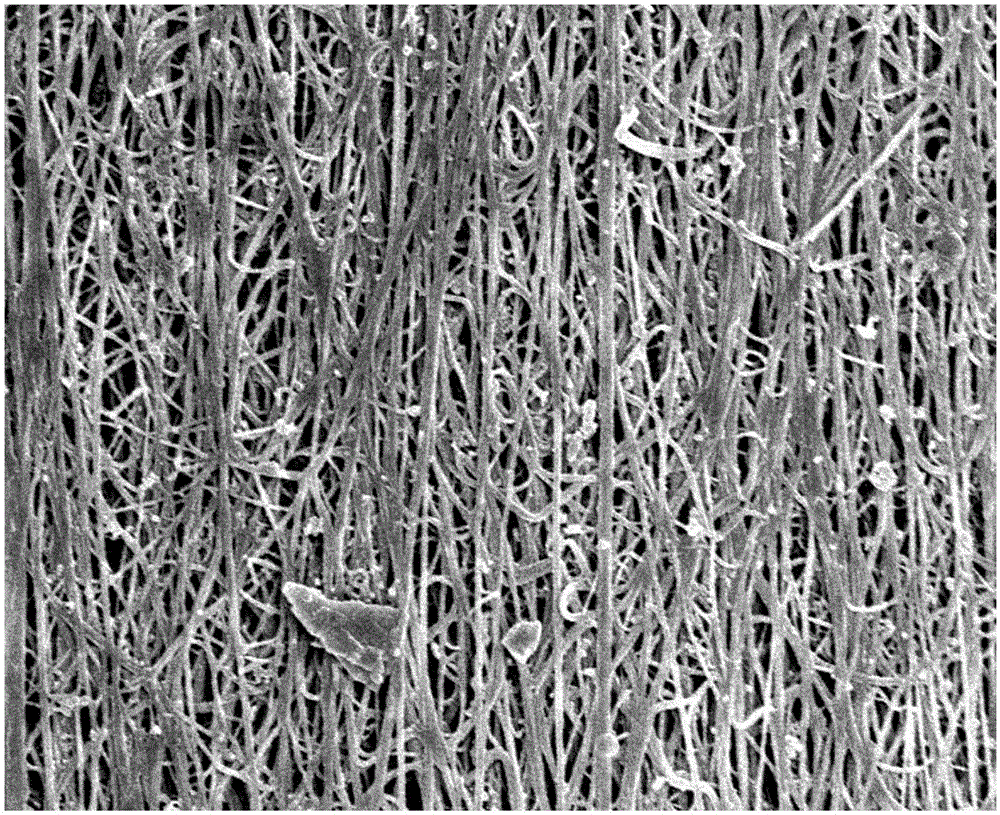

[0077] Apply the preparation method provided by the present invention, carry out drawing orientation by rollers, prepare a carbon nanotube film with a draft rate of 30%, and further compound with carbon fiber epoxy prepreg to prepare a carbon fiber epoxy film capable of lateral strain monitoring composite material. Specific steps are as follows:

[0078] The first step, the preparation of carbon nanotube film;

[0079] Under the protection of an inert gas, the mixture of ethanol, ferrocene and thiophene was injected into a high-temperature tube furnace at 1300° C. at a rate of 0.15 ml / min. The inert gas is a mixture of argon and hydrogen (volume ratio 1:1), and its flow rate is 4000 sccm. Continuous carbon nanotube aerogels are formed at the other end of the high-temperature tube furnace, and the carbon nanotube aerogels are collected by a winding device with a width of 5 cm and a diameter of 0.5 m. After collection, the carbon nanotube airgel was sprayed with ethanol to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Contact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com