Simulation testing device used for air vehicle rudder transmission mechanism

A transmission mechanism and simulation test technology, which is used in machine gear/transmission mechanism testing, machine/structural component testing, and mechanical component testing. It can solve the problems of low space utilization, product size limitations, and high costs. Achieve the effect of reducing test costs, strong adaptability, and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

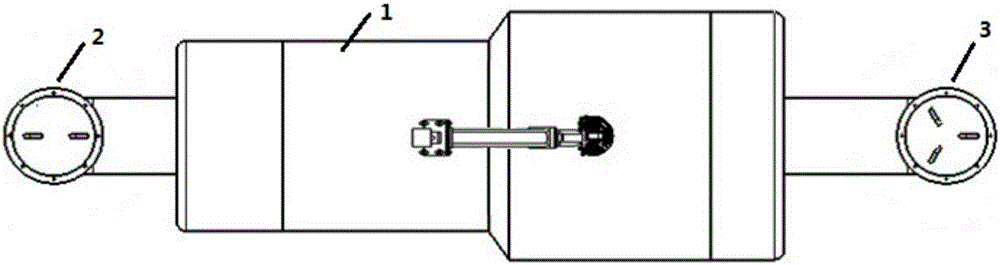

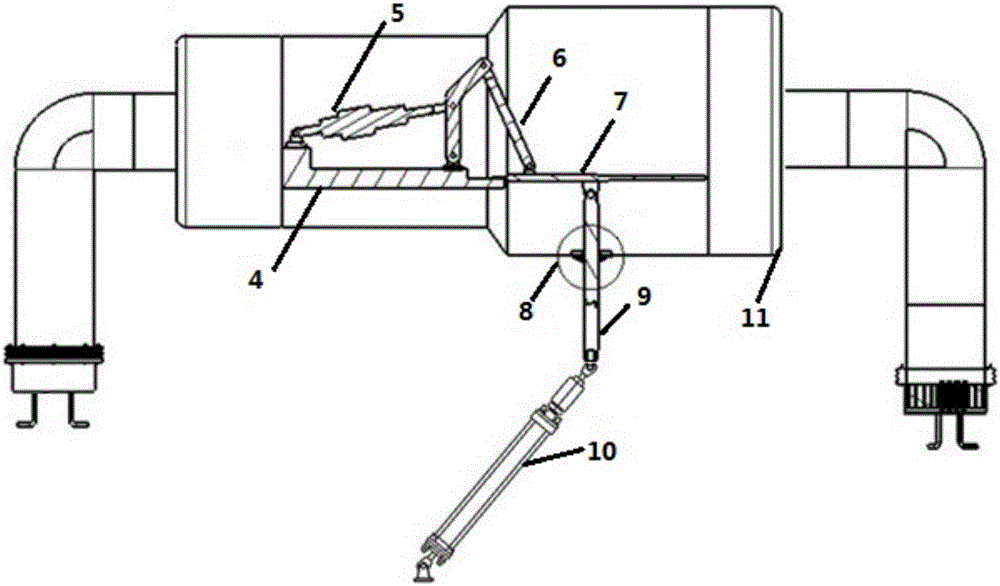

[0023] This embodiment is a simulation test device for the rudder transmission mechanism of an aircraft.

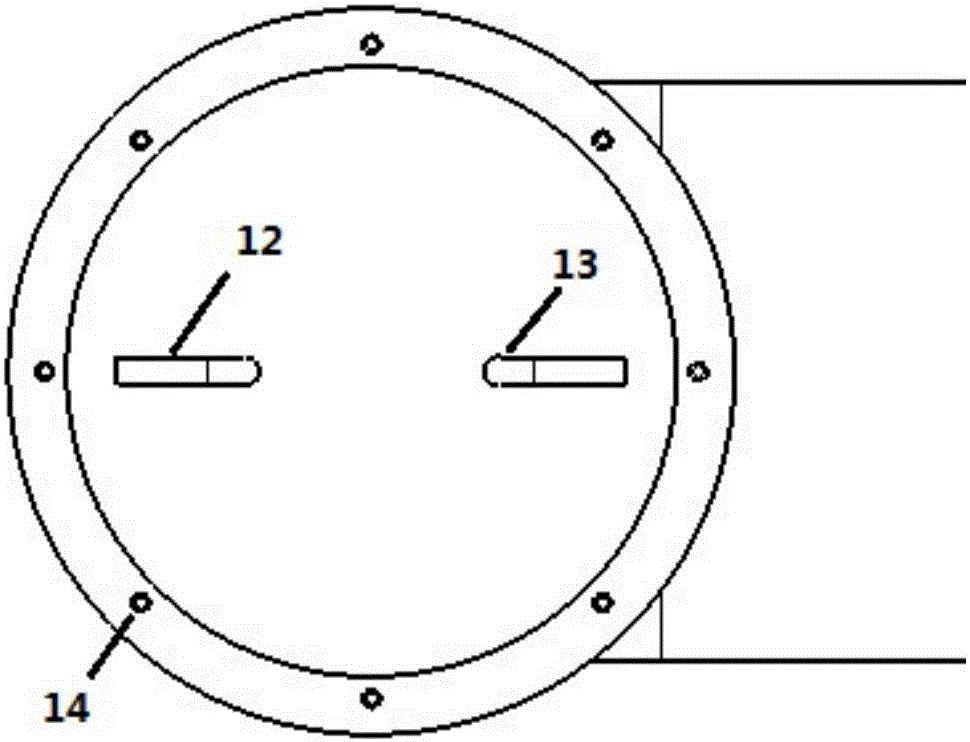

[0024] The simulation test device is used for the simulation test of the performance test of the rudder transmission mechanism in a high temperature environment or a low temperature environment. The simulation test device adopts non-vacuum thermal insulation material and internal support to make a flexible thermal insulation chamber; a static pressure chamber is set at the entrance and exit of the flexible non-vacuum environmental test chamber, so that high-temperature nitrogen or low-temperature nitrogen can evenly flow into the flexible non-vacuum environmental test chamber , in the flexible non-vacuum environment test chamber, a uniform high temperature simulation environment or low temperature simulation environment is realized; the simulation test device has a simple structure, reduces the test cost, and has a high space utilization rate.

[0025] refer to Figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com