Detection reagent and test paper for uric acid

A technology for detecting reagents and test papers, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions. It can solve the problems of high material requirements, complex processes, and complex test paper production processes. problem, to achieve the effect of strong anti-interference ability and eliminate interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

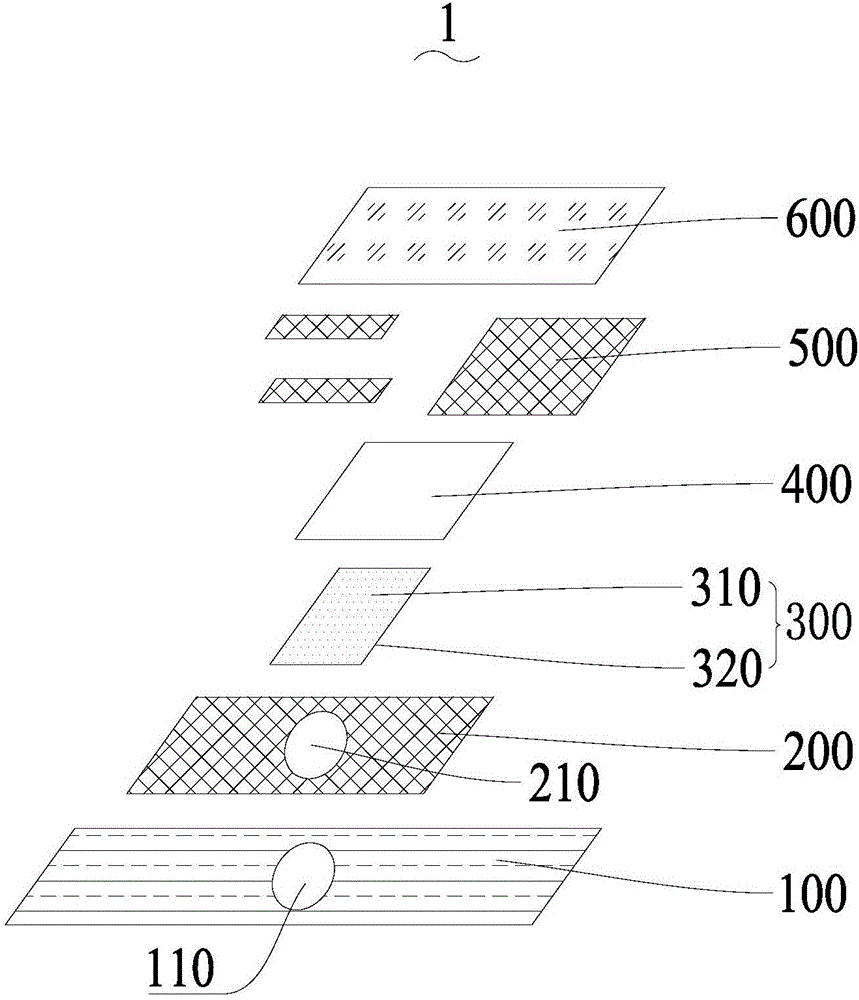

[0057] A detection test paper 1 for uric acid, its manufacture method comprises the following steps:

[0058] Step 1: Paste double-sided adhesive tape 200 on the reactive base layer 100 made of PET material with a certain hardness, and punch through holes 110 for later use.

[0059] Step 2. Tear off the oil paper of the double-sided adhesive 200 on the reaction base layer 100, and paste the film material 320 on the double-sided adhesive tape 200 of the PET board. The film material 320 needs to completely cover the through hole 110 on the PET substrate.

[0060] Step 3, first prepare detection reagent 310: 12KU / L of uric acid oxidase, 10KU / L of horseradish peroxidase, 15KU / L of ascorbate oxidase, 0.20g / L of 4-aminoantipyrine , 0.15mmol / L PBS buffer solution, 1.0g / L trehalose, 0.35g / L BSA and 0.30g / L chromogenic substance. Add the prepared detection reagent 310 dropwise to the corresponding through hole 110 of the membrane material 320 with a dispenser. After 20 minutes, the r...

Embodiment 2

[0064] In the preparation method of the uric acid detection test paper 1 of this embodiment, the detection reagent 310 includes 14KU / L uric acid oxidase, 9KU / L horseradish peroxidase, 16KU / L ascorbate oxidase, 0.25g / L 4-aminoantipyrine, 0.18mmol / L PBS buffer, 1.1g / L trehalose, 0.33g / L BSA and 0.28g / L chromogenic substance. Other steps are all the same as in Example 1.

Embodiment 3

[0066] In the preparation method of the uric acid detection test paper 1 of this embodiment, the detection reagent 310 includes 15KU / L uric acid oxidase, 8KU / L horseradish peroxidase, 18KU / L ascorbate oxidase, 0.28g / L 4-aminoantipyrine, 0.19mmol / L PBS buffer, 1.2g / L trehalose, 0.30g / L BSA and 0.25g / L chromogenic substance. Other steps are all the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com