Direct-writing type silk screen plate-making equipment and use method therefor

A screen plate making and direct writing technology, applied in the field of direct writing screen plate making equipment, can solve the problems of uneven energy distribution, short service life, uneven energy output distribution of digital micromirror devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

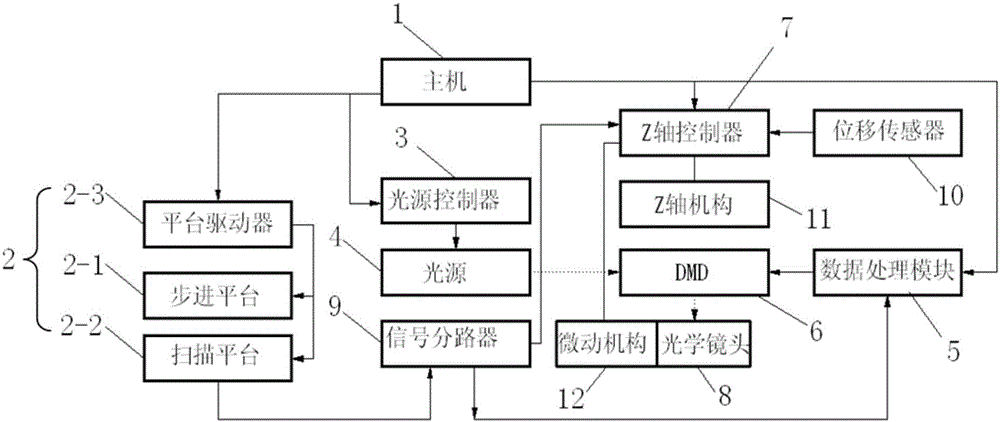

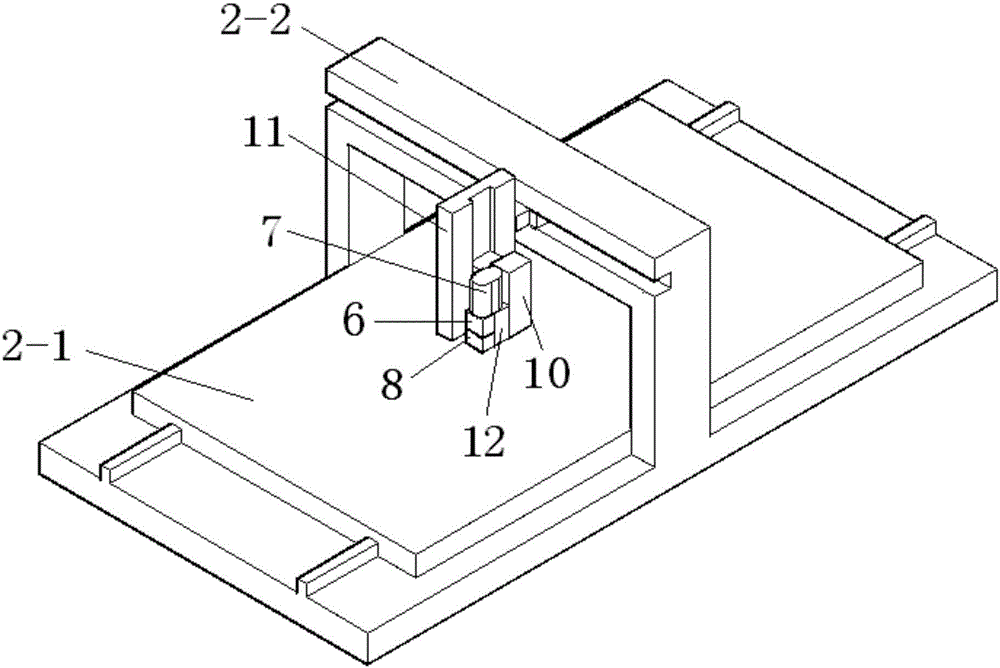

[0076] Refer to attached figure 1 And attached figure 2 , a direct-writing screen plate-making equipment, used for the plate-making process of screen printing, including a host 1, a motion system 2, a light source controller 3, a light source 4, a data processing module 5, a digital micromirror device 6, and a Z-axis control Device 7, optical lens 8, signal splitter 9, displacement sensor 10, Z-axis mechanism 11 and micro-motion mechanism 12;

[0077] The motion system 2 is composed of a stepping platform 2-1, a scanning platform 2-2 and a platform driver 2-3; wherein the platform driver 2-3 is connected with the host computer 1 for driving the stepping platform 2-1 and the scanning platform. platform 2-2 movement;

[0078] Described light source controller 3 is connected with main frame 1 and controls the switching status and light intensity of light source 4, and light source 4 is the light energy of continuous output that digital micromirror device 6 provides, and the li...

Embodiment 2

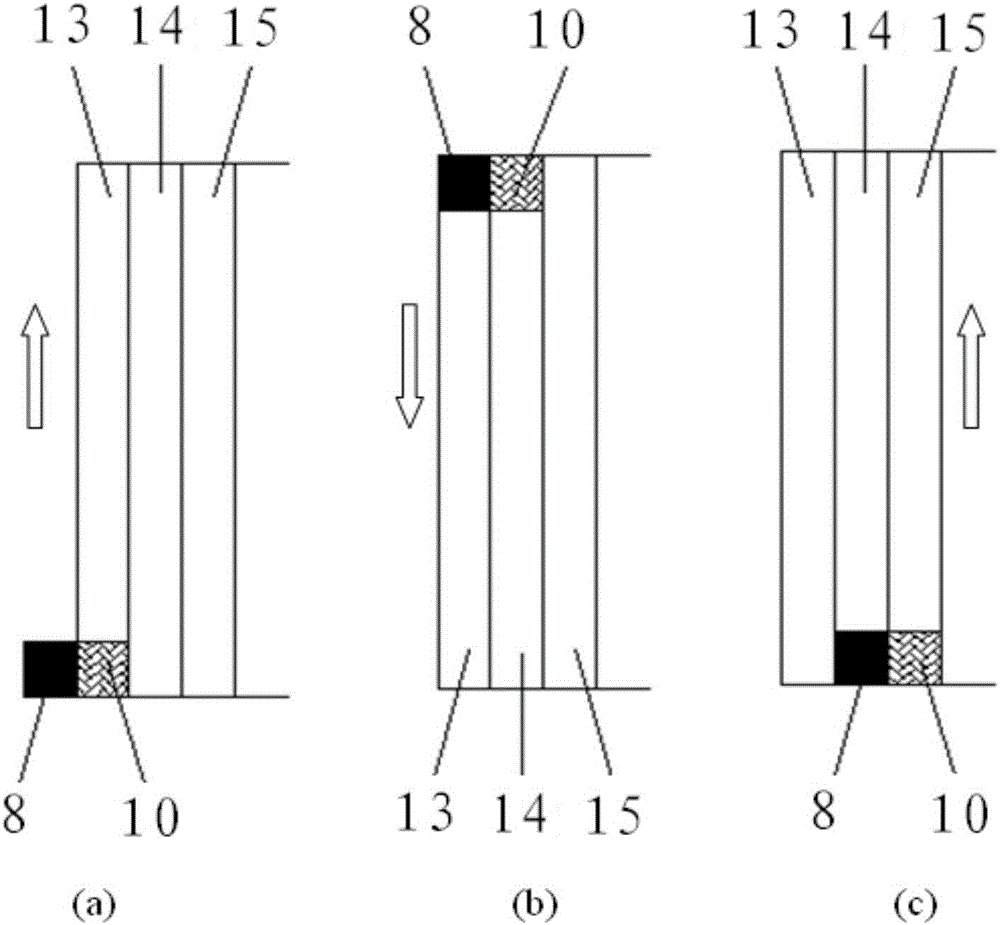

[0087] Refer to attached Figure 4 (b), attached Figure 4 (b) The scanning direction of the digital micromirror device 6 forms an included angle θ with the row direction of the entire array of micromirrors in the digital micromirror device. To repeat once, the image area 20 to be scanned is divided into subdivision blocks with a pitch of pw2, pw2=d×sinθ;

[0088] Refer to attached Figure 4 (a), attached Figure 4 (b) There is no angle between the scanning direction of the digital micromirror device 6 and the row direction of the entire array of micromirrors in the digital micromirror device, and the image area 20 to be scanned is divided into subdivided blocks with a pitch of pw1, pw1=d, because pw2=d×sinθ, obviously pw2 is less than pw1, when the scanning direction of the digital micromirror device 6 and the row direction of the micromirrors in the digital micromirror device form an included angle θ, the image area 20 to be scanned is divided More detailed, high data re...

Embodiment 3

[0101] The inclined laser direct writing technology cannot directly use the TIF image used in the printing field. The existing technology is to enlarge the image, but the amount of calculation and data in this process is extremely large. Compared with the prior art, the amount of computation and data in the processing process of this embodiment is small, and the obtained graphics have high resolution, which is conducive to the low-load operation of the equipment, and can improve the pattern refresh rate of the digital micromirror device (DMD).

[0102] In this embodiment, the TIF image is converted into a vector diagram, and the specific implementation process adopts the following process.

[0103] Refer to attached figure 1 , the TIF image processing method on the direct-write screen plate-making equipment is divided into the following steps:

[0104] (a) First install image processing software in host 1;

[0105] (b) setting the path and image processing parameters of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com