Method for preparing low-fat whipping cream from corn starch ultramicron type pickering emulsion

A Pickering emulsion, corn starch technology, applied in dairy products, cream preparations, applications, etc., can solve the problems of difficult to apply food emulsion production and processing, vascular diseases, negative effects on the human body, etc., achieve low fat content, Smooth taste and smooth shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

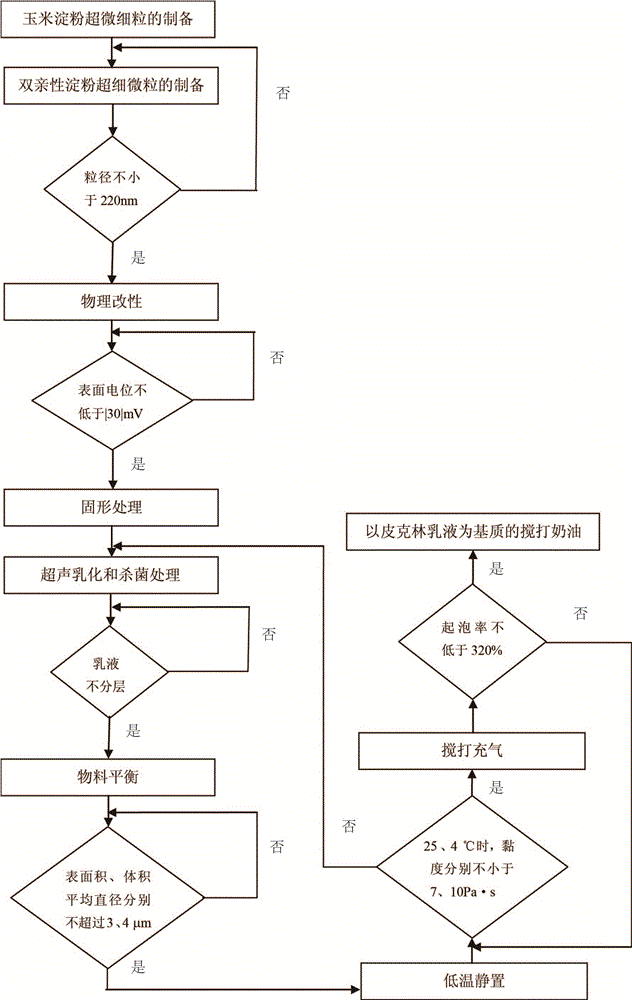

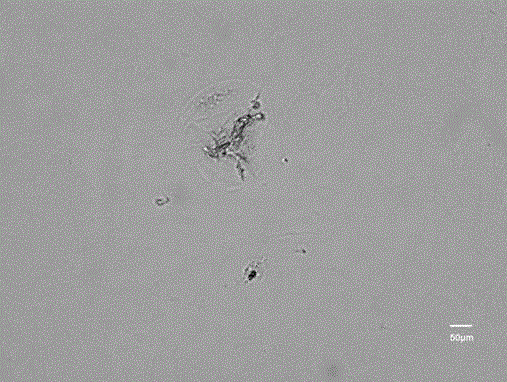

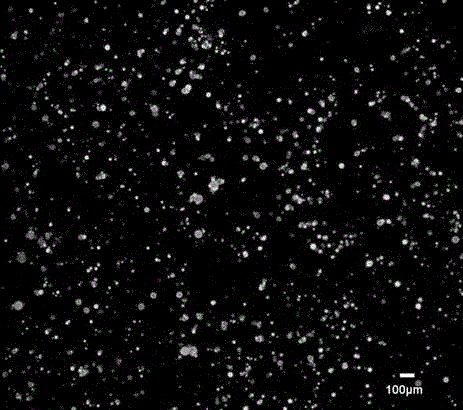

[0030] see figure 1 , figure 2 and image 3 as shown,

[0031] Step 1: Put the ordinary corn starch dispersion with a concentration of 10g / L in a constant temperature water bath at 100°C for heat treatment, so that the corn starch dispersion is in a sol state; use an adjustable speed titrator to dissolve the corn starch sol in micro-droplets Drop into 5 times the volume of absolute ethanol, fully stir the absolute ethanol with a speed-adjustable magnetic stirrer at a speed of 1rad / s, and use a centrifuge to centrifuge the absolute ethanol solution containing corn starch granules Processing, centrifugal force makes the cornstarch granules precipitate, reclaims the supernatant to extract absolute ethanol therefrom again; adds anhydrous ethanol with the same volume as the recovered supernatant to the precipitated cornstarch granules for secondary mixing, stirring and separation, and finally The obtained precipitate is corn starch ultrafine particles; this step is repeated 2 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com