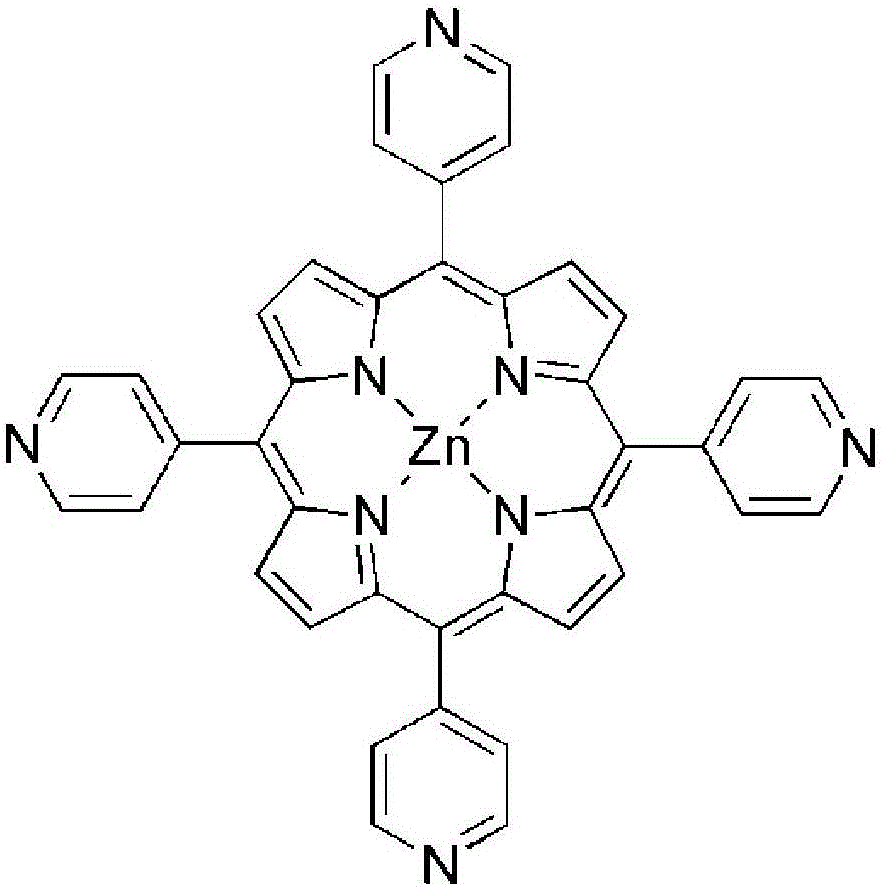

Tetra-(4-pyridyl) zinc porphyrin self-assembly nanocrystallization method

A pyridyl, zinc porphyrin technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of complex follow-up work, environmental pollution, complicated operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

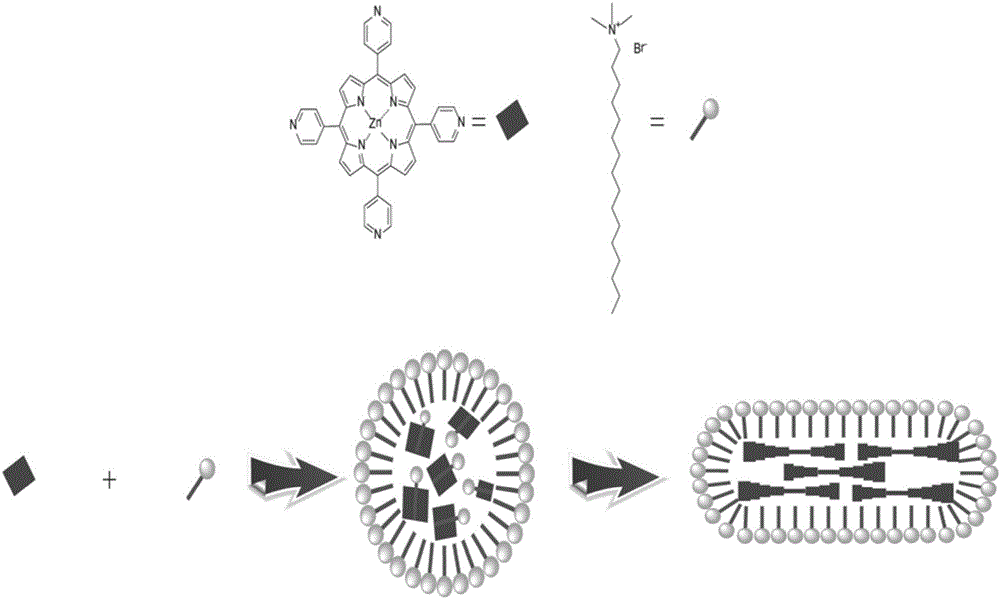

[0027] Embodiment 1: Four-(4-pyridyl) zinc porphyrin and 5mmol / L hexadecyltrimethylammonium bromide nanometerization, described method schematic diagram is as image 3 ,Proceed as follows:

[0028] (1) Four-(4-pyridyl) zinc porphyrin tetrahydrofuran mother liquor preparation and the reaction substrate concentration used

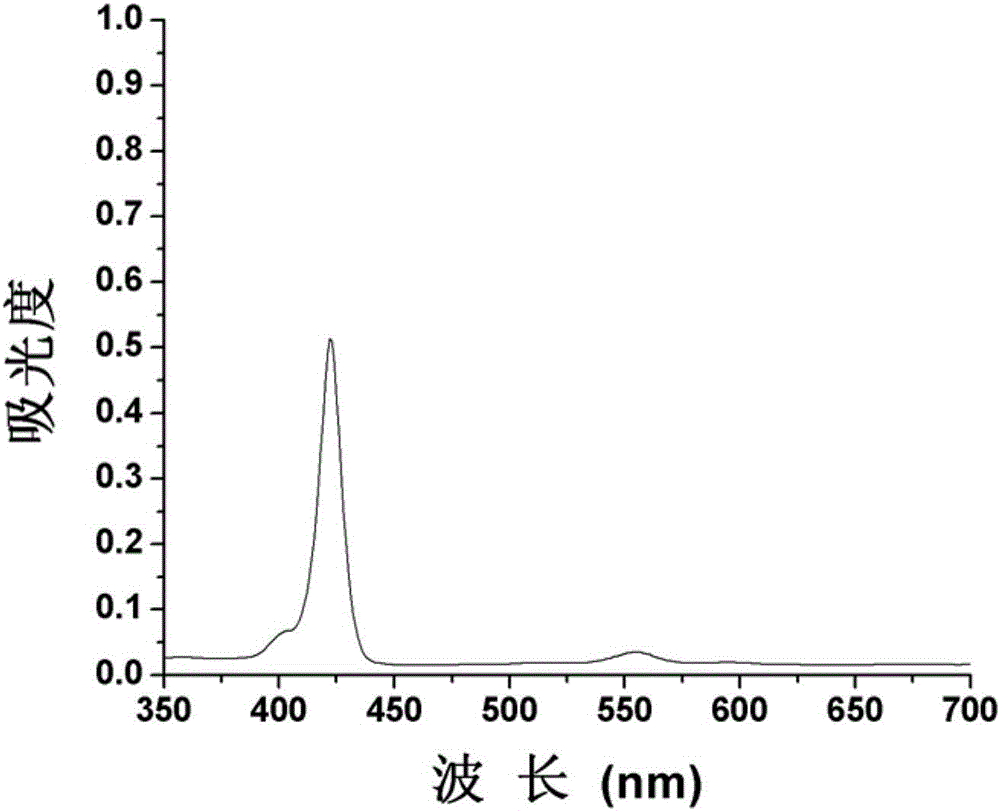

[0029] Place an appropriate amount of tetrakis-(4-pyridyl)zinc porphyrin in a 15mL EP tube, add tetrahydrofuran to make the volume to 10mL, and ultrasonically sonicate for 1 hour to completely dissolve the tetrakis-(4-pyridyl)zinc porphyrin, and prepare A tetrahydrofuran solution of tetrakis-(4-pyridyl)zinc porphyrin was obtained. The concentration of four-(4-pyridyl) zinc porphyrin tetrahydrofuran solution is calculated by Lambert-Beer's law by measuring the ultraviolet absorbance value at its 422nm place, and the molar absorptivity is 2.49×10 5 m -1 cm -1 . Thereby, calculate the concentration of four-(4-pyridyl) zinc porphyrin tetrahydrofuran mother l...

Embodiment 2

[0032] Embodiment 2: four-(4-pyridyl) zinc porphyrin and 2.5mmol / L hexadecyltrimethylammonium bromide nanometerization, the schematic diagram of the method is as follows image 3 ,Proceed as follows:

[0033] (1) The preparation of four-(4-pyridyl) zinc porphyrin tetrahydrofuran solution and the reactant concentration used adopt the method of step (1) in Example 1 to prepare four-(4-pyridyl) zinc porphyrin tetrahydrofuran solution And take the same reactant concentration, ie 3.42×10 -5 mol / L.

[0034] (2) Four-(4-pyridyl) zinc porphyrin and 2.5mmol / L hexadecyltrimethylammonium bromide nanometerization

[0035] Place 0.0092g of cetyltrimethylammonium bromide in a 15mL EP tube, add ultrapure water to make the volume to 10mL, and use an ultrasonic machine to sonicate for 5 minutes to completely dissolve the cetyltrimethylammonium bromide. Just prepare the 2.5mmol / L cetyltrimethylammonium bromide aqueous solution.

[0036] Pour the prepared 10mL cetyltrimethylammonium bromide aq...

Embodiment 3

[0037] Embodiment 3: Four-(4-pyridyl) zinc porphyrin and 0.5mmol / L hexadecyltrimethylammonium bromide nanometerization, the schematic diagram of the method is as follows image 3 ,Proceed as follows:

[0038] (1) Preparation of four-(4-pyridyl) zinc porphyrin tetrahydrofuran solution

[0039] Adopt the method preparation four-(4-pyridyl) zinc porphyrin THF solution among the embodiment 1 step (1) and take same reactant concentration, i.e. 3.42 * 10 -5 mol / L.

[0040] (2) Four-(4-pyridyl) zinc porphyrin and 0.5mmol / L hexadecyltrimethylammonium bromide nanometerization

[0041] Place 0.0018g of cetyltrimethylammonium bromide in a 15mL EP tube, add ultrapure water to make the volume to 10mL, and use an ultrasonic machine to sonicate for 5 minutes to completely dissolve the cetyltrimethylammonium bromide. Just prepare the aqueous solution of 0.5mmol / L cetyltrimethylammonium bromide.

[0042] Pour the prepared 10mL cetyltrimethylammonium bromide aqueous solution into a 150mL ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com