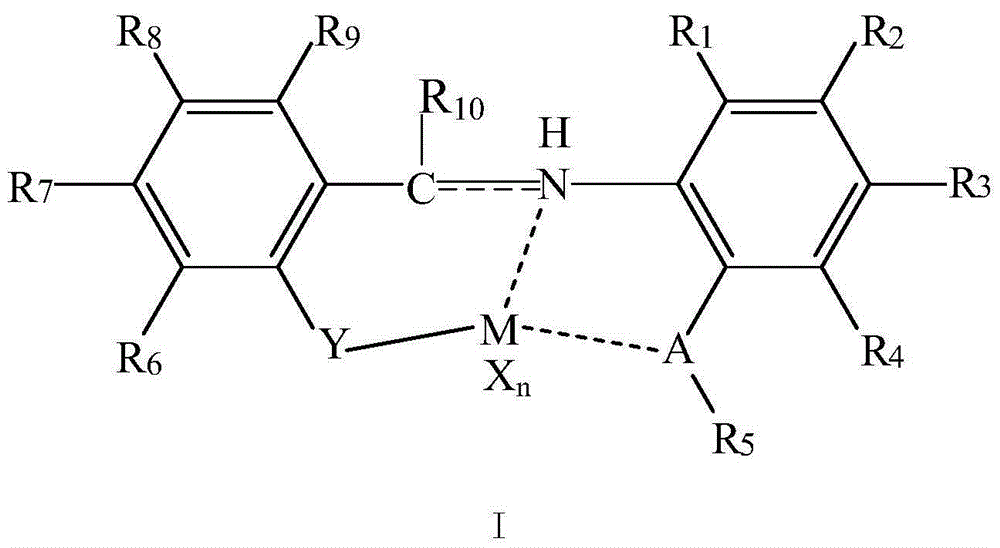

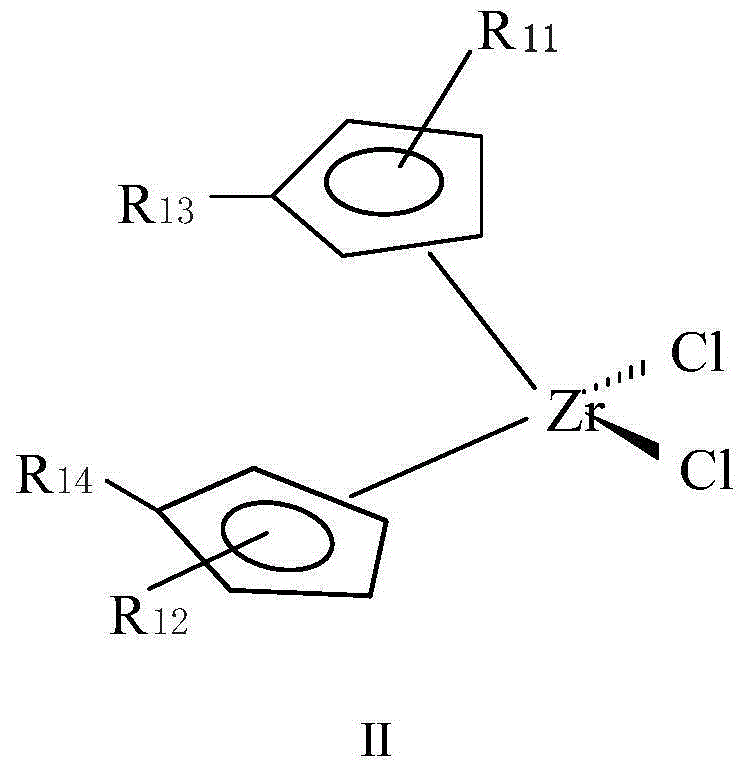

Double-active center composite catalyst and cycloolefin copolymer prepared from same

A cyclic olefin copolymer and composite catalyst technology, applied in the field of dual-active center composite catalysts, can solve the problems of poor processability, low polymerization activity of non-metallocene catalysts and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] What used in this embodiment is a 1L tank reactor. Dissolve 0.15 mol of refined norbornene in 500ml of refined toluene to form a solution, add the solution to a reactor that has been flushed with nitrogen, and punch ethylene (0.1MPa) several times to make the solution saturated with ethylene. Under the condition of 0.1MPa and stirring, add 23.8ml of toluene solution with a concentration of 1.72mol / L methylaluminoxane, 13.7μmol 3,5-di-tert-butylsalicylidene 2-propylthioaniline trichloride Titanium and 13.7μmol di-n-butyldichlorozirconocene dual-active center composite catalyst, during the polymerization process, ethylene is supplemented and metered, and the pressure is controlled at 0.1MPa.

[0033] After reacting for 0.5h, stop the reaction, pour the reaction solution into ethanol (composed of 150ml hydrochloric acid and 1000ml ethanol) containing 15% (v / v%) hydrochloric acid, filter after precipitation, after the filter cake is washed with ethanol (300ml), dry (dried ...

Embodiment 2

[0035] What used in this embodiment is a 1L tank reactor. Dissolve 0.15 mol of refined norbornene in 500ml of refined toluene to form a solution, add the solution to a reactor that has been flushed with nitrogen, and punch ethylene (0.1MPa) several times to make the solution saturated with ethylene. Under the condition of 0.1MPa and stirring, add 23.8ml of toluene solution with a concentration of 1.72mol / L methylaluminoxane, 0.13mmol of triethylaluminum, 13.7μmol of salicylidene 2-methylthioaniline trichloride Titanium and 13.7 μmol dimethyl dichlorozirconocene composite catalyst with dual active sites, during the polymerization process, ethylene is supplemented and metered, and the pressure is controlled at 0.1 MPa.

[0036] After reacting for 0.5h, the reaction was stopped, and the reaction solution was poured into ethanol containing 15% (v / v%) hydrochloric acid (consisting of 150ml hydrochloric acid and 1000ml ethanol) and filtered after precipitation, and the filter cake w...

Embodiment 3

[0038] What used in this embodiment is a 1L tank reactor. Dissolve 0.15 mol of refined norbornene in 500ml of refined toluene to form a solution, add the solution to a reactor that has been flushed with nitrogen, and punch ethylene (1MPa) several times to make the solution saturated with ethylene. Under the condition of stirring, 23.8ml of toluene solution with a concentration of 1.72mol / L methylaluminoxane, 13.7μmol of 3,5-di-tert-butylsalicyl 2-mercaptoaniline titanium trichloride and 13.7μmol of di The dual-active center composite catalyst of n-butyl dichlorozirconocene, the polymerization process is supplemented by metering ethylene, and the control pressure is 1MPa.

[0039] After reacting for 0.5h, the reaction was stopped, and the reaction solution was poured into ethanol containing 15% (v / v%) hydrochloric acid (consisting of 150ml hydrochloric acid and 1000ml ethanol) and filtered after precipitation, and the filter cake was washed with ethanol (300ml) and dried ( 60 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com