Polyamide porous microspheres and preparation method thereof

A technology of porous microspheres and polyamides, applied in the field of polymer materials, can solve problems such as inability to control, and achieve the effects of easy implementation, narrow size distribution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

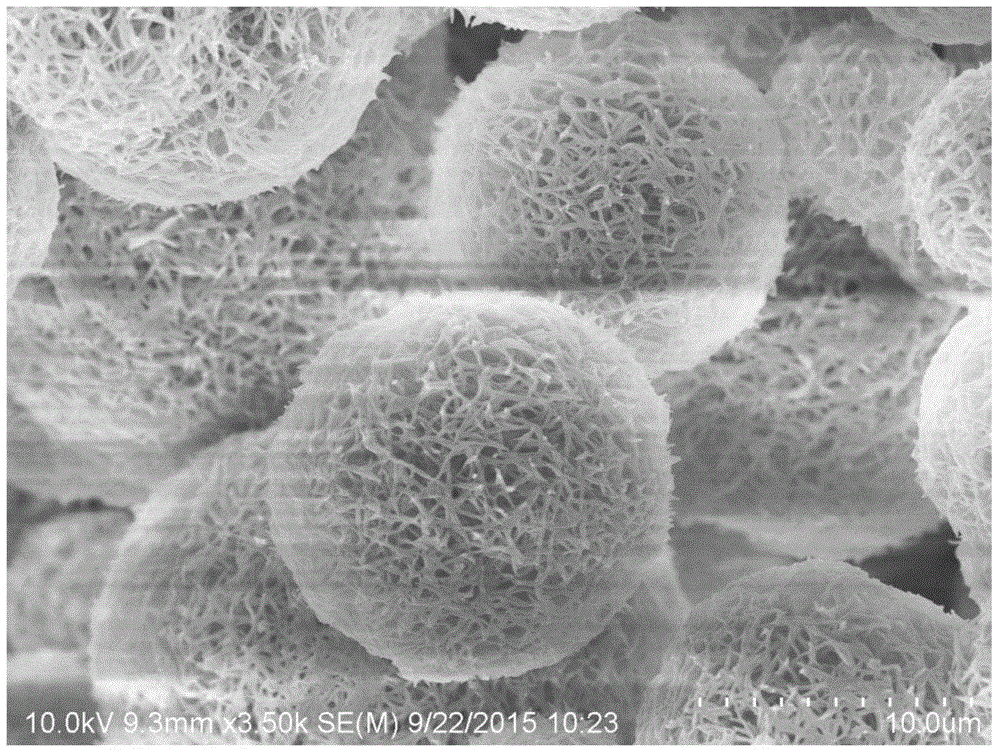

[0038] Add 20g of nylon 6 pellets and 240ml of formic acid into the reaction kettle and heat up to 80°C, stir for 2 hours to fully dissolve the materials, then add 400ml of ethanol solution with a concentration of 10% g / ml polyvinylpyrrolidone (PVP), stir vigorously, and placed, the powder was precipitated. Suction filtration, washing with ethanol, and vacuum drying to obtain polyamide porous microspheres; figure 1 The scanning electron micrographs of the polyamide porous microspheres prepared by this method can be seen from the figure, the average size of the microspheres is 10um, and the surface pore size is uniform. The BET specific surface area of the microspheres measured by the specific surface meter is 35m 2 / g, the maximum pore size is 1um. The particle size distribution coefficient of the microspheres measured by the laser particle size analyzer is 0.91.

Embodiment 2

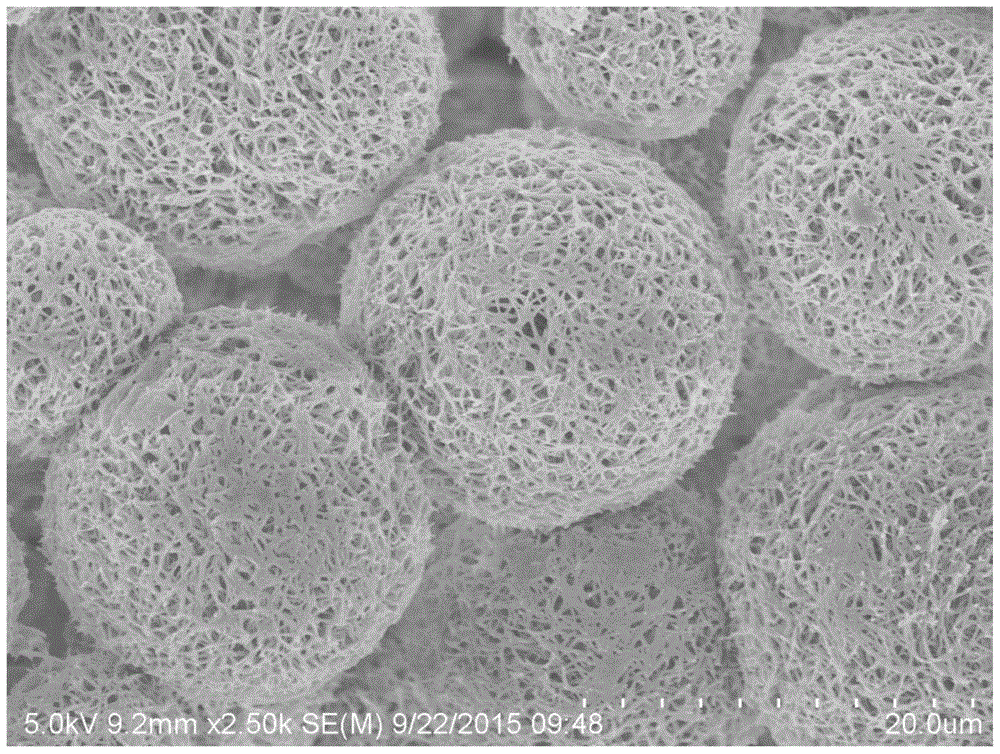

[0040] Add 28g of nylon 6 pellets and 240ml of formic acid into the reaction kettle and heat up to 80°C, stir for 2 hours to fully dissolve the materials, then add 400ml of ethanol solution with a concentration of 10% g / ml polyvinylpyrrolidone (PVP), stir vigorously and let it stand placed, the powder was precipitated. Suction filtration, washing with ethanol, and vacuum drying to obtain polyamide porous microspheres; figure 2 Scanning electron micrographs of polyamide porous microspheres prepared by this method. It can be seen from the figure that the average size of the microspheres is 20um, and the surface pore size is uniform. The BET specific surface area of the microspheres measured by the specific surface meter is 32m 2 / g, the maximum pore size is 1um. The particle size distribution coefficient of the microspheres measured by the laser particle size analyzer is 0.94.

Embodiment 3

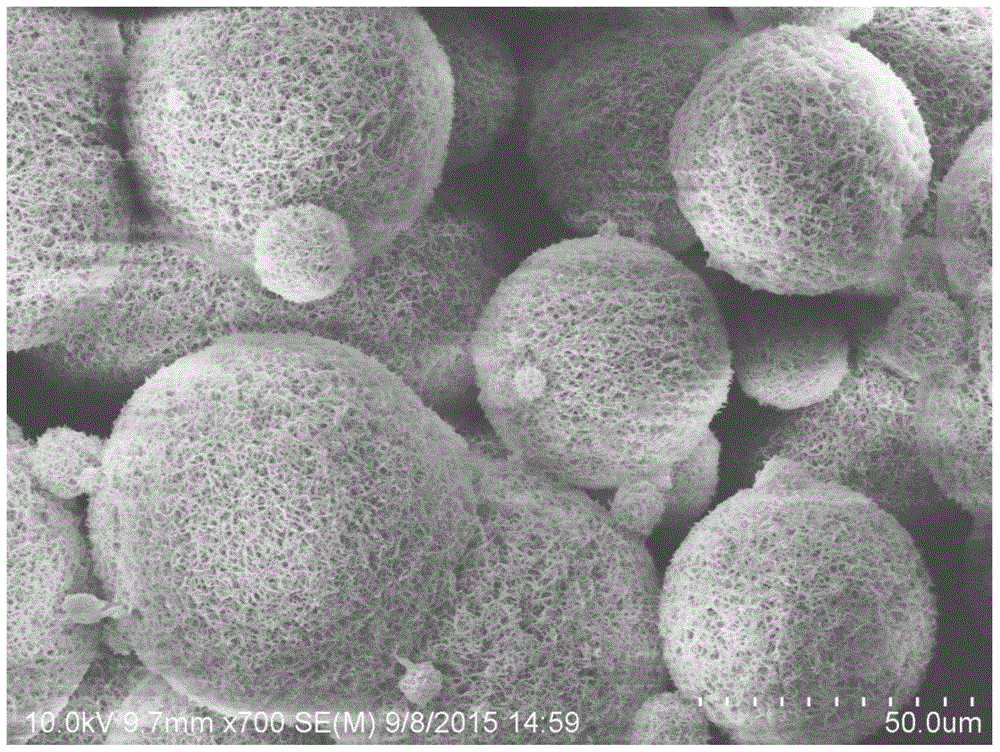

[0042] Add 40g of nylon 6 pellets and 240ml of formic acid into the reaction kettle and heat up to 80°C, stir for 2 hours to fully dissolve the material, then add 400ml of ethanol solution with a concentration of 10% g / ml polyvinylpyrrolidone (PVP), stir vigorously, and placed, and the powder was precipitated. Suction filtration, washing with ethanol, and vacuum drying to obtain polyamide porous microspheres; image 3The scanning electron micrographs of the polyamide porous microspheres prepared by this method can be seen from the figure, the average size of the microspheres is 50um, and the surface pore size is uniform. The BET specific surface area of the microspheres measured by the specific surface meter is 30m 2 / g, the maximum pore size is 2um. The particle size distribution coefficient of the microspheres measured by the laser particle size analyzer is 1.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com