Algae species breeding method of microalgae capable of tolerating high-concentration flue gas

A technology for microalgae and algae species, which is applied in the methods of using microorganisms, methods based on microorganisms, biochemical equipment and methods, etc., can solve the problems of large screening workload and low efficiency, and achieve high sugar content and high efficiency. , the effect of less workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

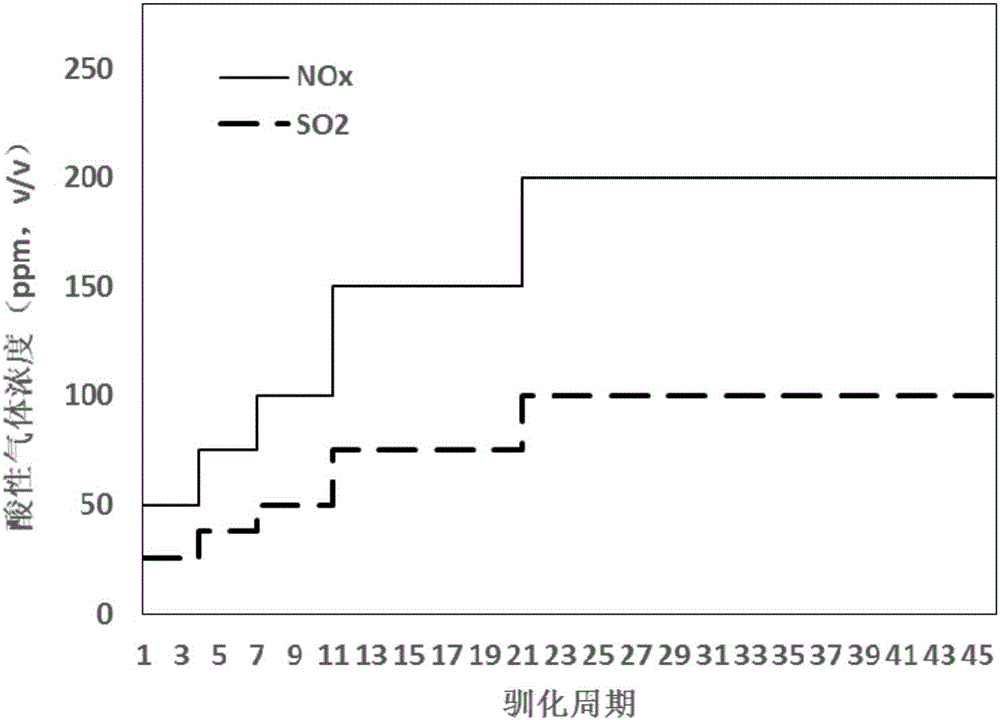

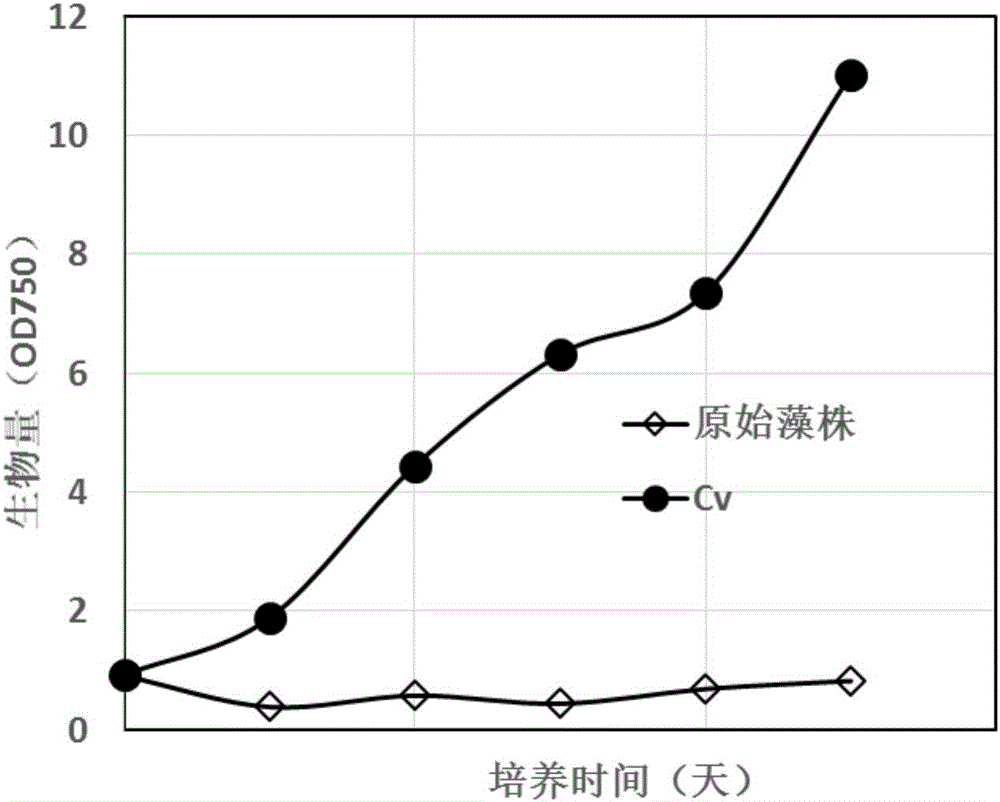

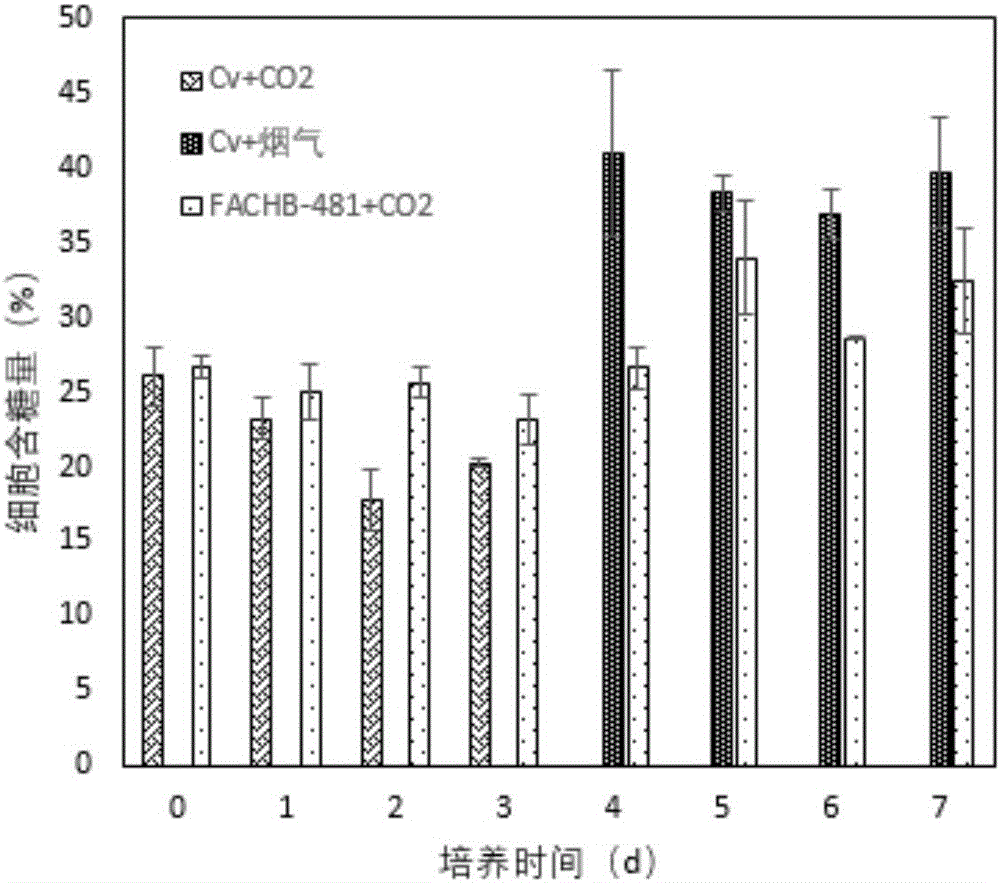

[0041] Purchase a strain of Chlorella vulgaris FACHB-481 (hereinafter referred to as the original strain) from the freshwater algae stock. The algae strain was exposed to gradually increasing concentrations of flue gas (see figure 1 ) under 46 cycles of evolution to obtain Chlorella Cv, and the medium is BG11 medium.

[0042] Adaptive evolution culture conditions: the initial inoculation density of microalgae is 0.35g / L, the temperature is 28°C; the apparent ventilation rate is 0.3vvm; the light intensity is about 100μmol / m 2 / s, continuous light; the Cv ventilation method is specifically the flue gas ventilation on the first day of each cycle, and 10% CO in the remaining two days 2 Ventilation; the culture system is 350ml. The initial acclimation gas concentration is CO 2 10%+NOx50ppm+SO 2 25ppm, the evolution time of each cycle was set to 3 days, and each group of experiments was set up with 3 parallels. When the chlorella died, the surviving parallel group of chlorell...

Embodiment 2

[0048] A Scenedesmus strain FACHB-489 was cultivated, and the continuous aeration mode was adaptively evolved for 200 cycles, and the medium was BG11.

[0049] Adaptive evolution culture conditions: the initial inoculation density of microalgae is 0.2g / L, the temperature is 20°C; the apparent ventilation rate is 0.1L / min; the light intensity is about 50μmol / m 2 / s, continuous lighting. Continuous flue gas ventilation, the culture system is 350ml, and the initial acclimation gas concentration is 5% CO 2 +40ppmNOx+20ppmSO 2 . The evolution time of each cycle is set to 2 days, the flue gas is passed on the first day, and 10% CO is passed on the second day 2 . After 40 cycles of culture, increase the flue gas concentration by 1% CO 2 , 40ppm NOx, 20ppmSO 2 And cultured for 40 cycles. Until the flue gas concentration is 10% CO 2 , 200ppm NOx and 100ppm SO 2 . The evaluation test proved the improvement of the tolerance of Scenedesmus to flue gas before and after domesticat...

Embodiment 3

[0051] Nannochloropsis (GY-H14, Shanghai Guangyu Biotechnology Co., Ltd.) was evolved for 45 cycles of intermittent flue gas aeration under gradually increasing flue gas concentration to obtain domesticated strains. The medium is TAP medium.

[0052] Adaptive evolution culture conditions: the initial inoculation density of microalgae is 0.5g / L, the temperature is 35°C; the apparent ventilation rate is 0.5vvm; the light intensity is about 500μmol / m 2 / s, continuous lighting. The initial acclimation gas concentration is CO 2 10%+NOx 50ppm+SO 2 25ppm, the evolution time of each cycle was set to 5 days, and each experiment set 3 parallels. The ventilation method is specifically flue gas for the first 2 days of each cycle, and 10% CO for the remaining 3 days 2 . Each stage was cultivated for 15 cycles, and then the flue gas concentration was increased to 0% CO 2 , 50ppm NOx, 25ppm SO 2 , and cultivated for another 15 cycles, and gradually increased until the concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com