Processing method of high-elasticity light and thin composite yarns

A processing method, light and thin technology, applied in the direction of yarn, thin material treatment, coating, etc., can solve the problems of poor product quality, unreasonable components, etc., and achieve the effect of good product quality and good grasping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0055] The processing method of the high-elastic light and thin type composite yarn comprises the following steps:

[0056] a. Purchase nylon elastic yarn and viscose filament as raw materials, and check whether the raw materials meet the quality indicators of the national textile industry;

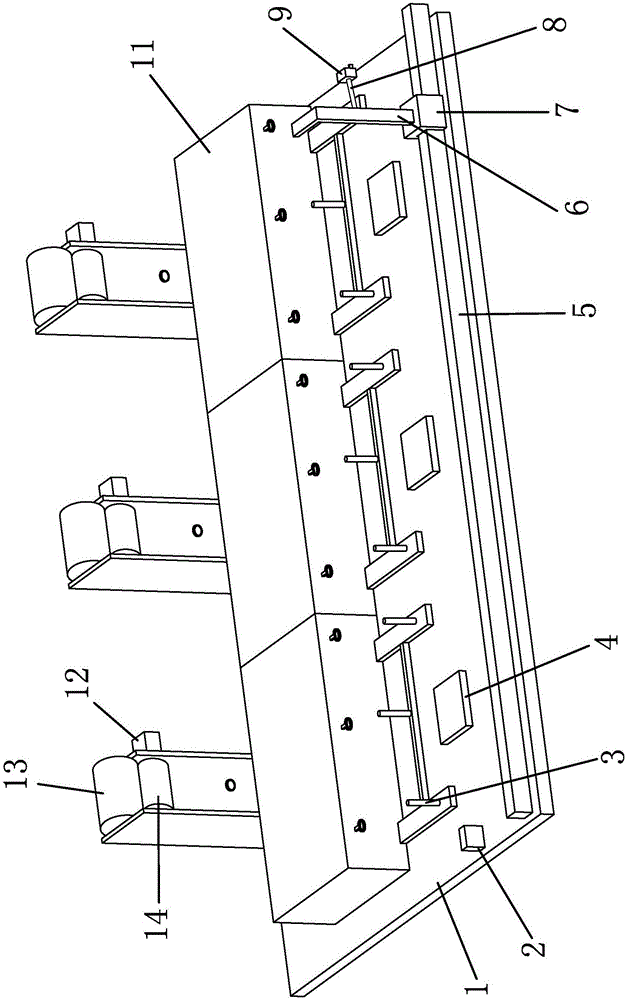

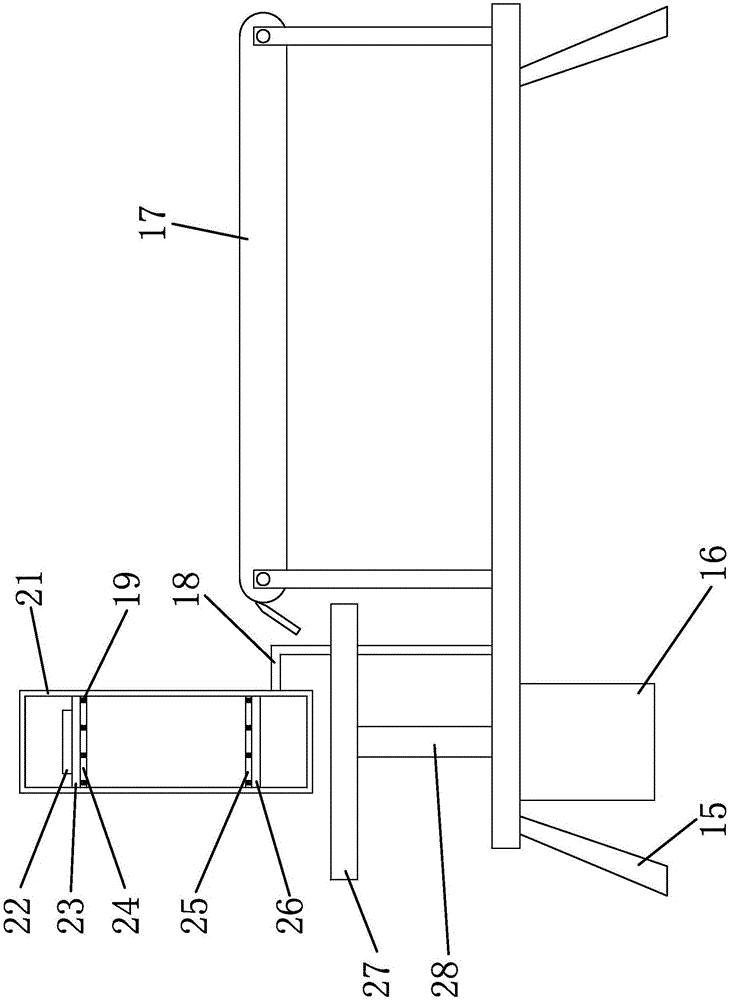

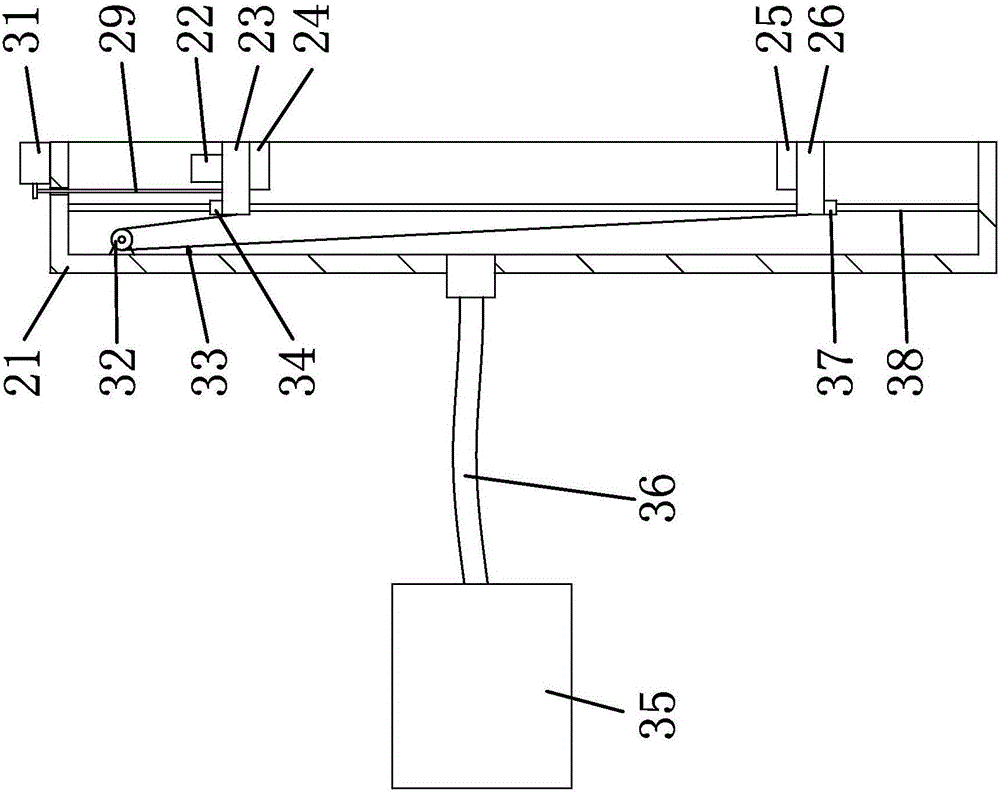

[0057] b. Doubling 3-5 nylon elastic filaments and 2-3 viscose filaments through a doubling device, and then twisting to form a composite yarn; in this embodiment, 4 nylon elastic filaments and 2 The viscose filaments are combined through the yarn combining device;

[0058] c. Pour 50-70 parts of silicone polyurethane water-based coating, 5-8 parts of antibacterial agent, 3-7 parts of antistatic agent, 2-3 parts of coupling agent, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com