Multifunctional temperature control double-cavity pressure chamber

A pressure chamber and multi-functional technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems of easy water leakage, temperature gradient, inconvenient installation, etc., to ensure accuracy, Guarantee the effect of stability and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

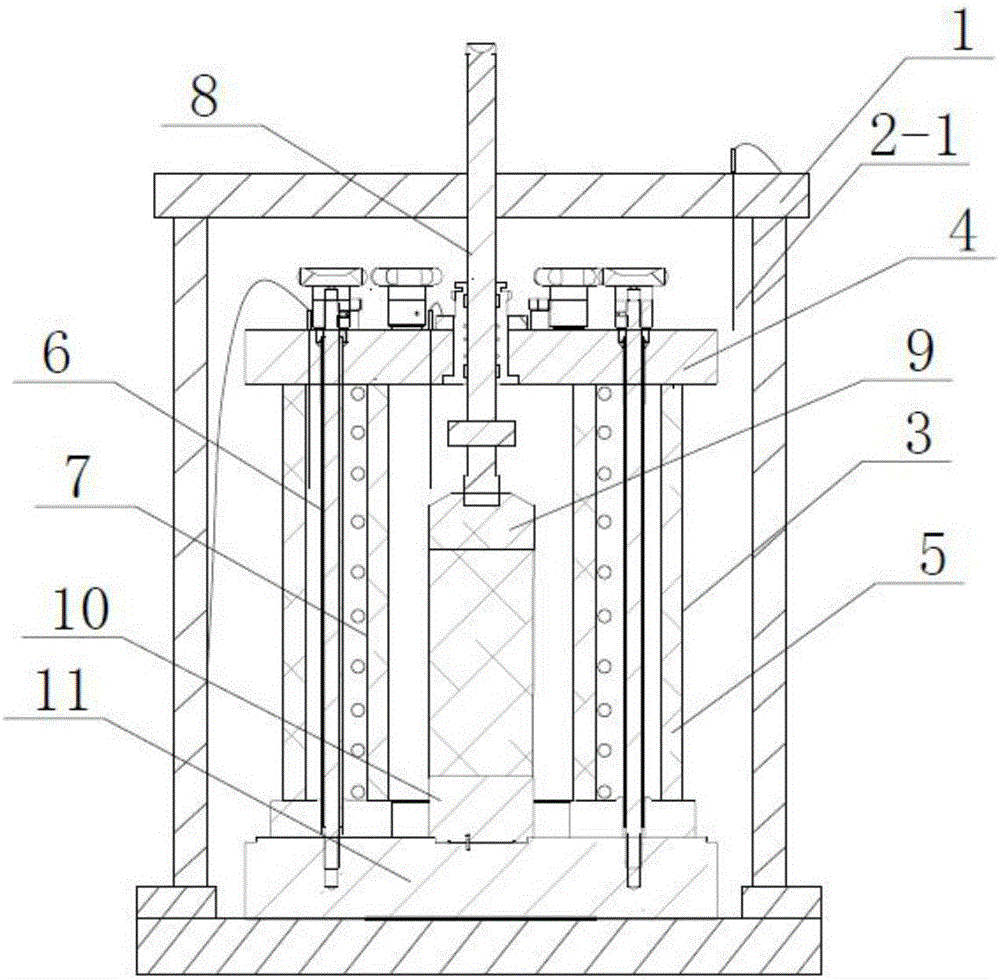

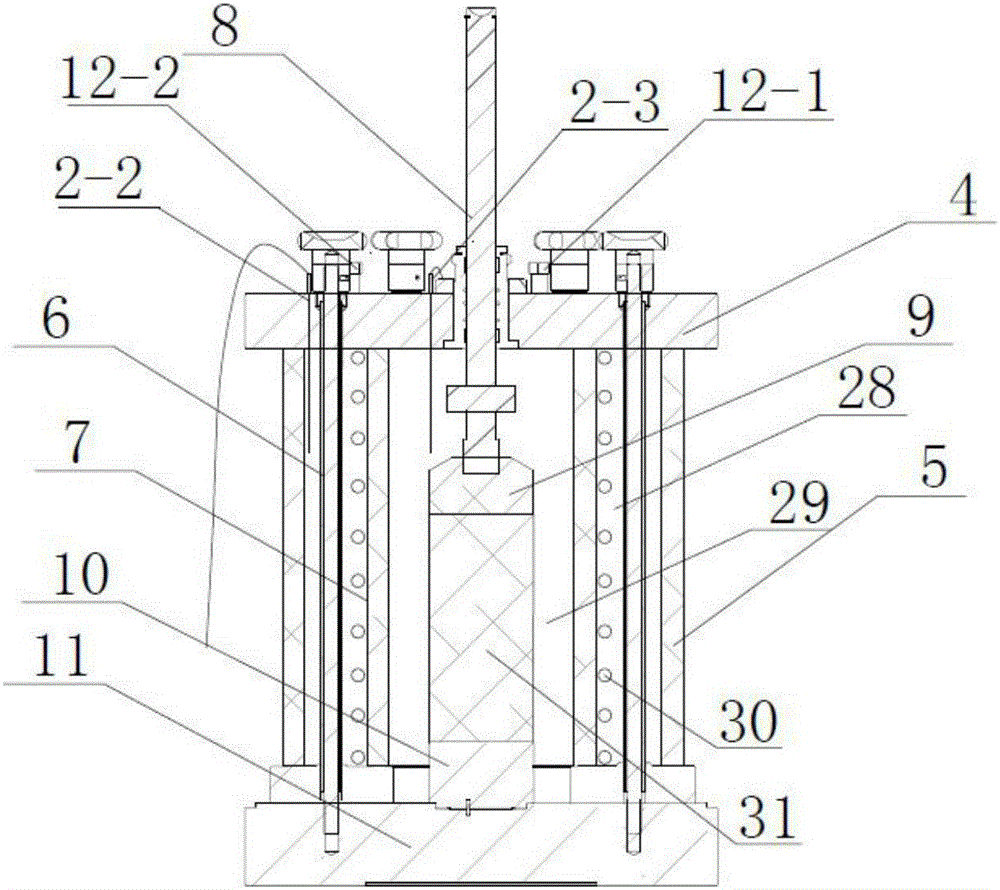

[0038] Such as Figures 1 to 8 As shown, a multifunctional temperature-controlled double-chamber pressure chamber includes a temperature control system and a pressure chamber system; the temperature control system includes a thermostat 1, a first temperature sensor 2-1, and a second temperature sensor 2-2 , the third temperature sensor 2-3 and the water bath circulating copper tube 3;

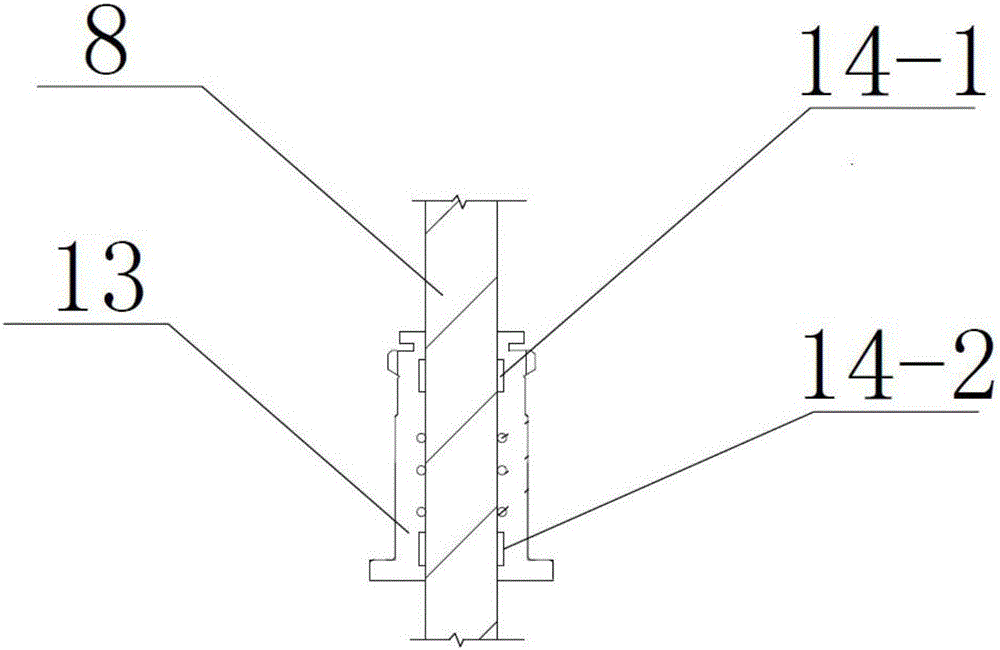

[0039] The pressure chamber system is placed in the incubator 1, and the pressure chamber system includes a pressure chamber base 11, an organic glass cylinder 5 installed on the pressure chamber base 11 and an aluminum alloy cylinder 7 located inside the organic glass cylinder 5, and an organic glass cylinder 7 installed on the organic glass cylinder. The upper cover 4 on the top of the glass cylinder 5 and the aluminum alloy cylinder 7; the upper cover 4, the plexiglass cylinder 5, the aluminum alloy cylinder 7 and the pressure chamber base 11 are sealed and connected by a tie rod 6; the pres...

Embodiment 2

[0052] The multifunctional temperature-controlled double-chamber pressure chamber structure of the present invention can carry out saturated triaxial tests and unsaturated triaxial tests. When performing saturated triaxial tests, only the first high-pressure ball valve 24-1 on the pressure chamber base 11, The third high-pressure ball valve 24-2 and the fifth high-pressure ball valve 24-5 can be closed. When performing an unsaturated triaxial test, only the second high-pressure ball valve 24-3 on the pressure chamber base 11 needs to be closed. Unsaturated soil stress, seepage and other multi-factor coupling tests.

Embodiment 3

[0054] The multifunctional temperature-controlled double-chamber pressure chamber structure of the present invention can carry out tensile test. Before the test, the built-in load sensor 8 is fixed by the clamp 38, and the anti-pressure cap 9 connected with the built-in load sensor 8 is kept inseparable from the sample 31. Load contact, the test begins to use the test loading device to stretch the built-in load cell 8 to complete the tensile test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com