Color developing agent for detecting benzene gas, gas detection tube and manufacturing method and application of gas detection tube

A technology of color developer and gas detection tube, which is applied in the field of gas detection tube and gas detection color developer, which can solve the problems of inability to perform rapid on-site analysis, inconvenient portability, and the need for power supply, etc., to achieve large-area point distribution and low price , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0021] Preparation of developer

[0022] 1. Fix 1.5mg silica gel and 1m L H 2 SO 4 , select the amount of paraformaldehyde. Prepared developer:

[0023]

[0024] The "observation phenomenon" and "boundary line" in the table are the following experiments. Add 1.5mg of pretreated silica gel and 1.0mL of concentrated sulfuric acid to five beakers respectively, add the amount of paraformaldehyde in the five examples, and stir evenly , Install the tube under the infrared light environment, and observe the phenomenon and the boundary after one hour. When loading the tube, put the silica gel carrier into the two ends of the glass tube respectively, put the glass tube into the Erlenmeyer flask with benzene gas for experiment, you can see the color phenomenon and the boundary line.

Embodiment 6-10

[0026] 2. First fix 1.5mg of silica gel and 100.0mg of paraformaldehyde in the following table, and select the amount of concentrated sulfuric acid. Prepared developer:

[0027]

[0028] The "observation phenomenon" and "boundary line" in the table are to do the following experiment. Add 1.5mg of pretreated silica gel and 100.0mg of paraformaldehyde to five beakers respectively, add the amount of concentrated sulfuric acid in the five examples, and stir evenly , Install the tube under the infrared light environment, and observe the phenomenon and the boundary after one hour. When loading the tube, put the silica gel carrier into the two ends of the glass tube respectively, put the glass tube into the Erlenmeyer flask with benzene gas for experiment, you can see the color phenomenon and the boundary line.

Embodiment 11

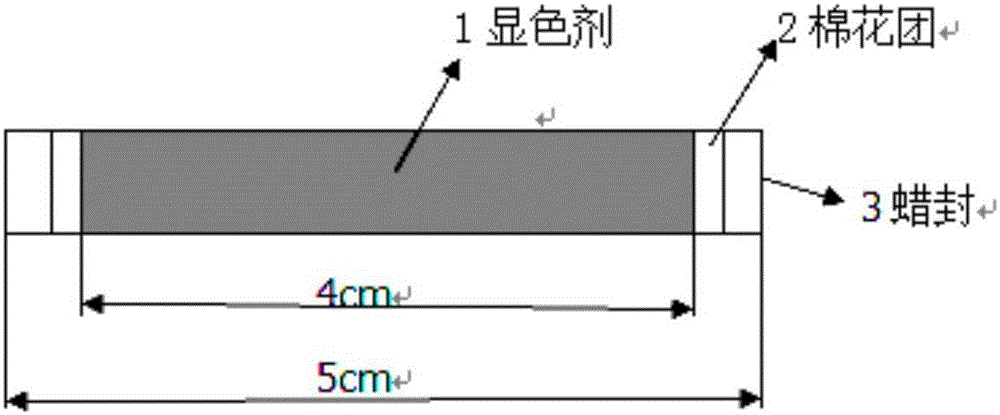

[0030] The manufacture of the gas detection tube includes the following steps

[0031] (1) Pretreatment of silica gel

[0032] Put 80---100 mesh silica gel in the flask, add 1:1H 2 SO 4 -HNO 3 Mixed acid, the acid content should be 1-2cm higher than the surface of the silica gel, place it for 8-10 hours, pour off the acid solution, soak it in hot tap water, wash off the remaining acid, then soak it in boiling distilled water, and filter until the pH value of the distilled water soaked overnight is at 5 or more, and then use the barium chloride turbidimetric method to test until there is no SO 4 2- until. After the silica gel is washed, it is dried in an oven at 110°C, activated at 500°C for 2 hours, and sealed in a container for storage after activation.

[0033] (2) Preparation of developer

[0034] Weigh 3.0g of the processed silica gel into a small beaker, then weigh 0.2g of paraformaldehyde and grind it into a powder in a grinder, pour the paraformaldehyde into the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| degree of freedom | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com