Photovoltaic heat collection plate of semicircle pipe flow channel

A heat collecting plate and semi-circular tube technology, which is applied in the field of heat collecting plates for photovoltaic cells, can solve the problems of low photoelectric efficiency, increase the contact area between refrigerant flow channels and solar panels, achieve uniform temperature distribution, and reduce surface average Effects of temperature and increase in contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

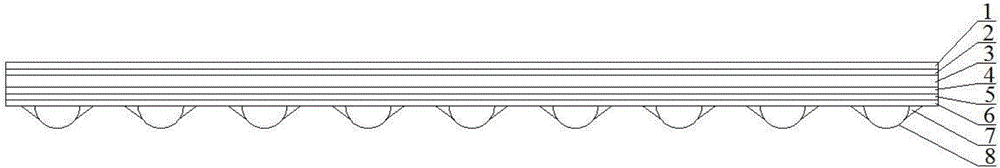

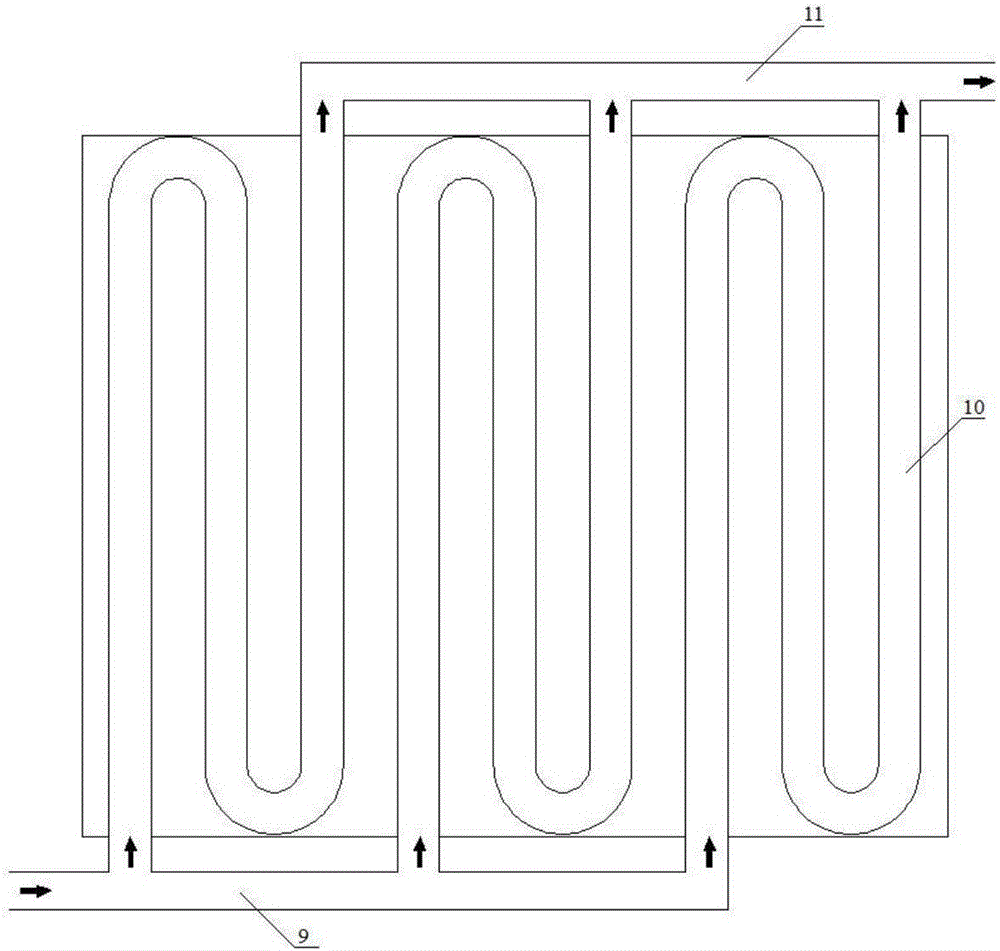

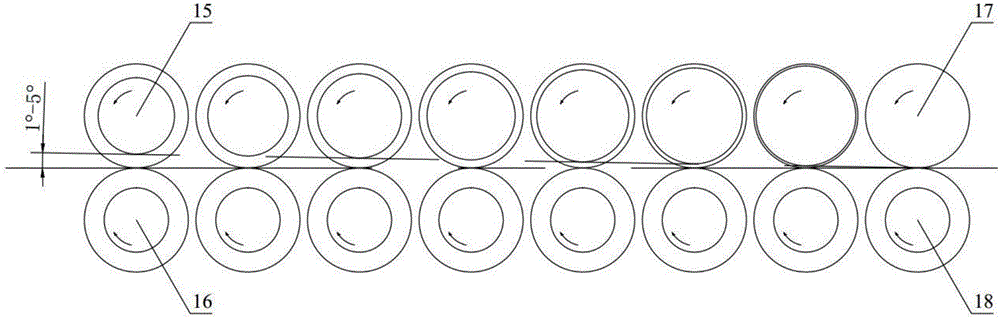

[0021] Such as figure 1 As shown, the photovoltaic heat collecting plate of the present invention is composed of a photovoltaic heat collecting plate and a refrigerant flow channel below. Photovoltaic heat collectors have a layered structure from top to bottom, which are composed of surface protection layer 1, EVA film 2, photovoltaic cell layer 3, EVA film 4, TPT insulating layer 5, and aluminum back plate layer 6. The surface protection layer 1 adopts materials with high transmittance such as ultra-clear glass, and the TPT insulating layer 5 adopts black materials to better absorb solar radiation energy. Surface protection layer 1, EVA adhesive film 2, photovoltaic cell layer 3, EVA adhesive film 4, TPT insulating layer 5, and aluminum back sheet layer 6 are bonded together by lamination technology to form a photovoltaic cell panel, under the aluminum back sheet lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com