Method for preparing high-throughput ultrafiltration membrane from nano calcium carbonate doped polysulfone

A technology of nano-calcium carbonate and ultrafiltration membrane, applied in chemical instruments and methods, membranes, membrane technology, etc., can solve limited problems, increase the amount of addition, improve pore-making effect, etc., and achieve simple process and mild preparation conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

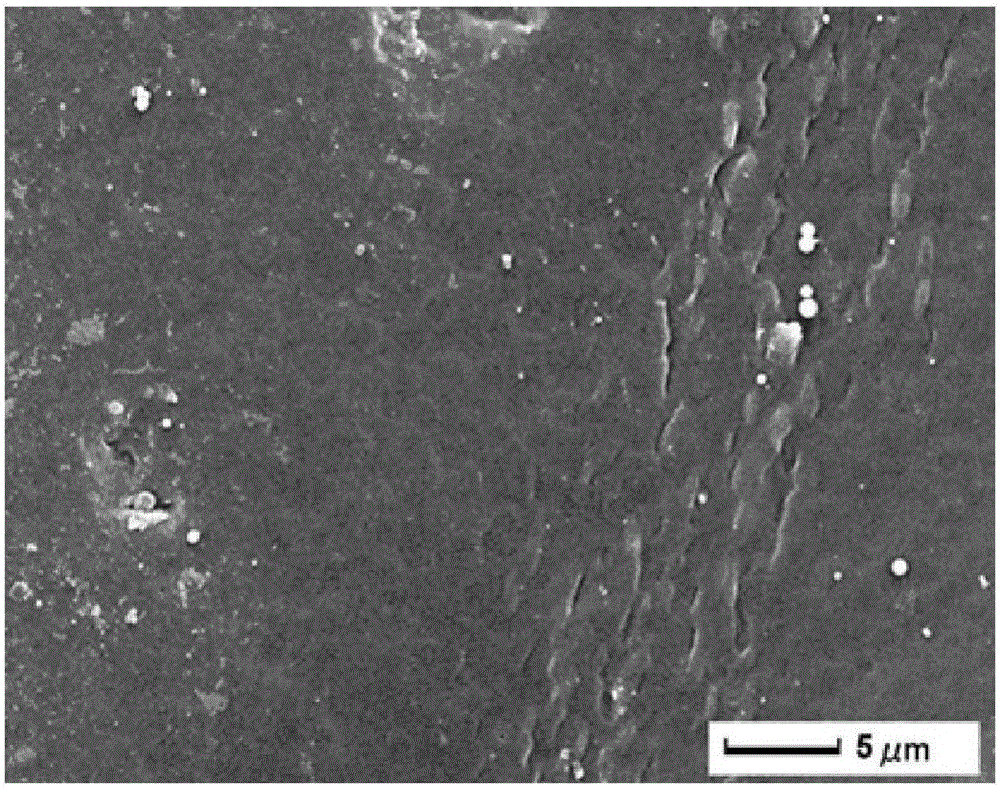

Embodiment 1

[0035] Add 5g of calcium carbonate to 80g of N-methylpyrrolidone (NMP), ultrasonically disperse for 30 minutes, then add 15g of dried polysulfone, heat in an oil bath at 80°C, and prepare a uniform casting solution. Step 3. Flat membrane preparation: After filtering and defoaming the casting solution, scrape it evenly on a clean glass plate with a scraper, and transfer it into water to form a membrane. After desolvation, soak in 1.2mol / L hydrochloric acid solution for 20 minutes, take it out and wash it with deionized water until pH=7 of the eluate, and store the obtained membrane in deionized water for later use.

Embodiment 2

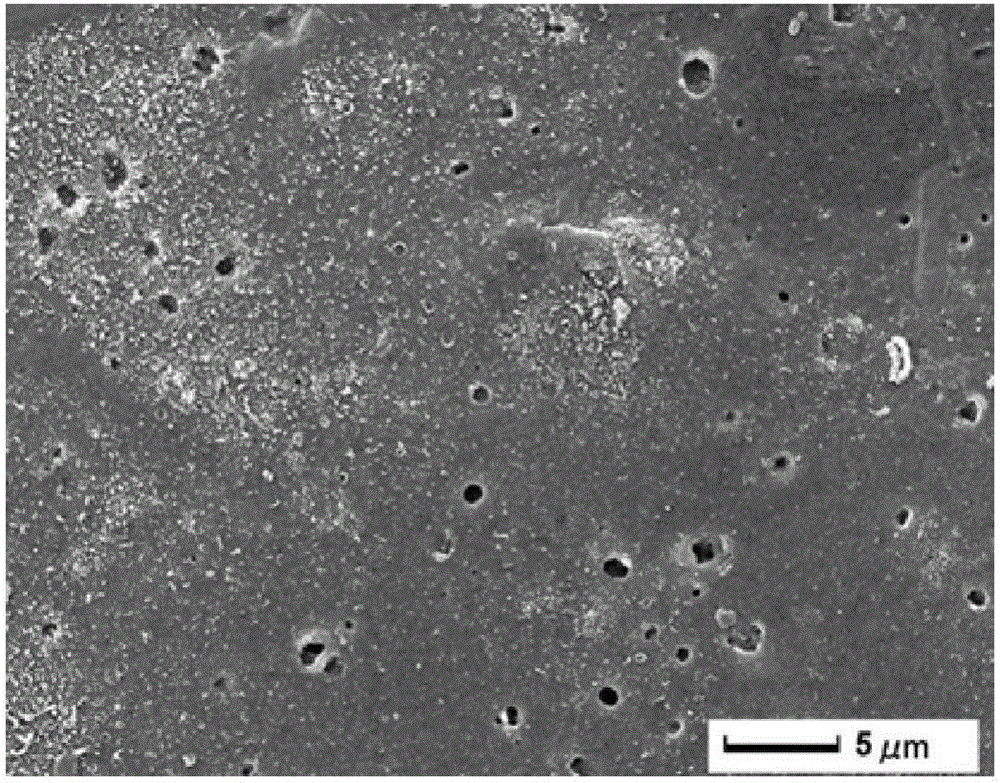

[0037] Weigh 7.5 g of nano-calcium carbonate and add it to 80 g of NMP, ultrasonically disperse for 30 minutes, then add 15 g of dry-treated polysulfone to it, heat in an oil bath at 80°C, and prepare a uniform casting solution. After filtering and defoaming, evenly hang it on a clean glass plate with a spatula, and then transfer it into water for phase inversion to form a film. After desolvation, soak in 1.2mol / L hydrochloric acid for 20min. Take out and rinse with deionized water until the pH of the eluate is 7, and set aside.

Embodiment 3

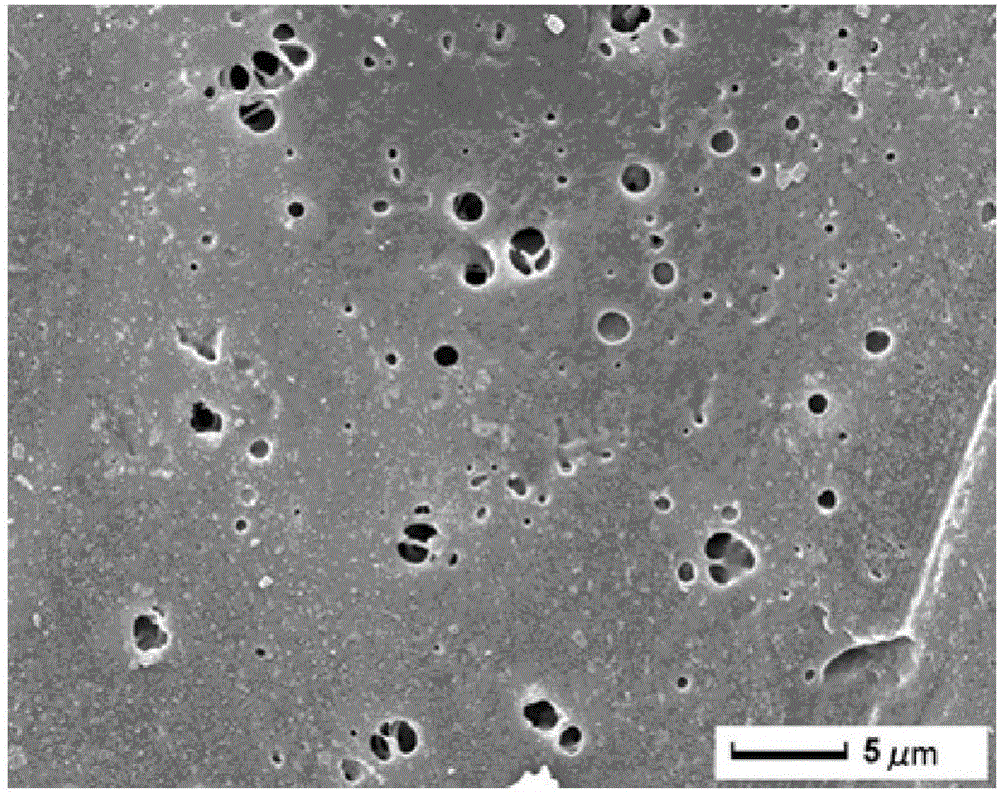

[0039] Weigh 10 g of nano-calcium carbonate and add it to 80 g of NMP, ultrasonically disperse for 30 minutes, then add 15 g of dry-treated polysulfone to it, heat in an oil bath at 80°C, and prepare a uniform casting solution. After filtering and defoaming, evenly hang it on a clean glass plate with a spatula, and then transfer it into water for phase inversion to form a film. After desolvation, soak in 1.2mol / L hydrochloric acid for 20min. Take out and rinse with deionized water until the pH of the eluate is 7, and set aside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com