Semi-submersible type offshore aquaculture facility modified based on container freighter

A container and semi-submersible technology, applied to fishing boats, etc., can solve the problems that the oil and gas industry is not suitable for the offshore farming industry, the conversion utilization rate of container ships is low, and it is not economical and practical, so as to improve the quality of life of the people and facilitate timely transfer , the effect of creating tourism income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

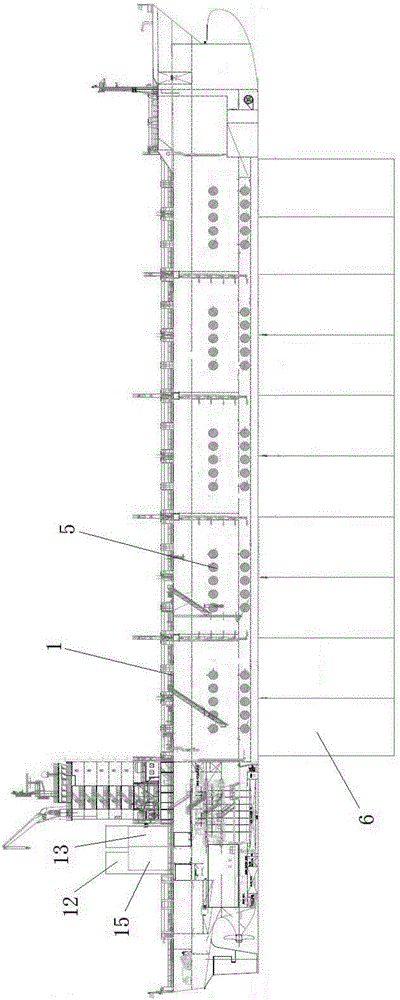

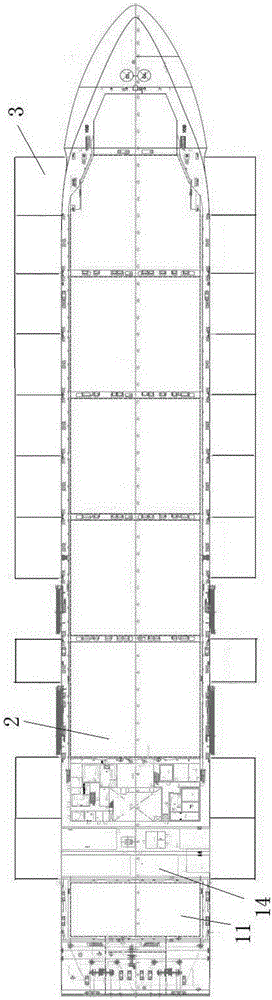

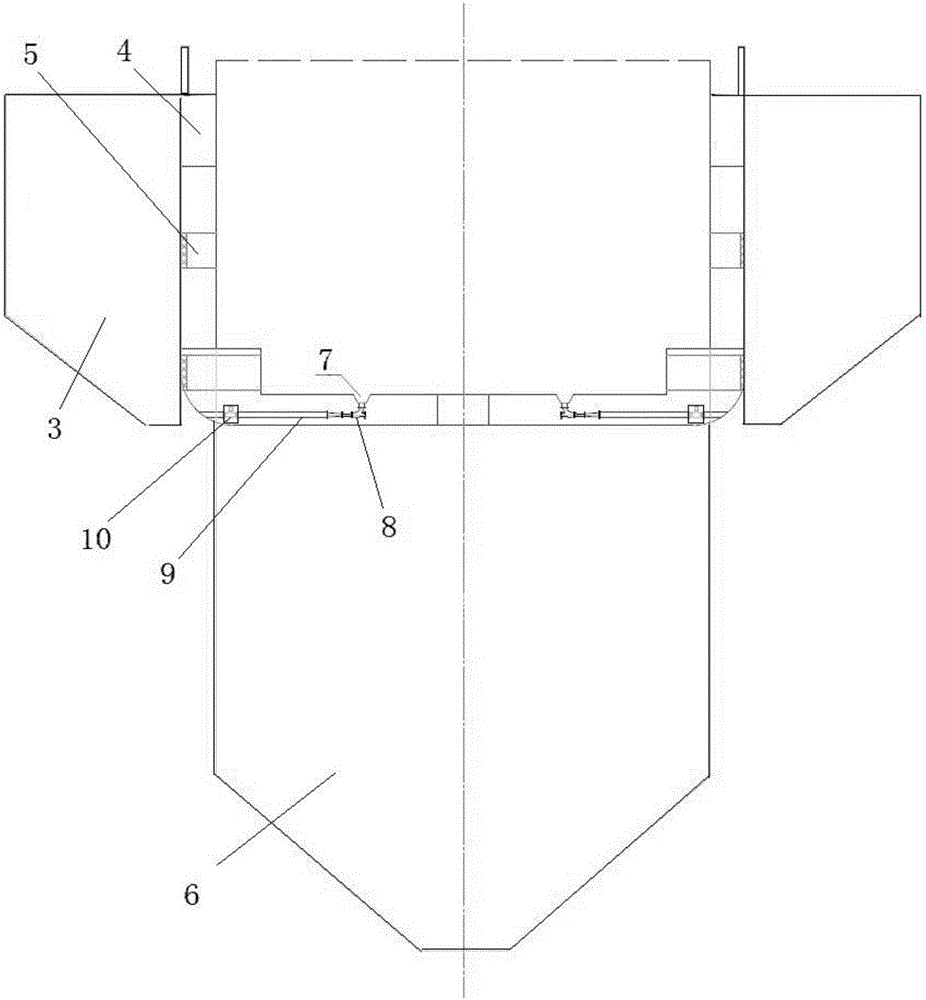

[0021] Attached below Figure 1-3 To further explain the present invention:

[0022] Semi-submersible offshore breeding facilities modified based on container cargo ships, equipped with equipment rooms and auxiliary breeding cabins, mooring devices are installed at the front of the breeding facilities, diesel engine rooms are installed at the rear of the breeding facilities, and the diesel engine rooms are equipped for power generation There are several breeding cabins 2 distributed below deck 1. The breeding cabins 2 are converted from container cargo holds. The side walls of the breeding cabins 2 are provided with cavities 4 for buoyancy for the breeding facilities. The outer wall of the facility is connected to the cage 3 and communicated through a number of water exchange holes 5, and the bottom of the breeding cabin 2 is connected to the bottom cage 6.

[0023] The breeding cabin 2 is provided with an aeration system, and the bottom of the breeding cabin 2 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com