Pressure sensor and preparation method thereof

A pressure sensor and pressure technology, applied in piezoelectric devices/electrostrictive devices, fluid pressure measurement using capacitance changes, piezoelectric/electrostrictive/magnetostrictive devices, etc. Good and other problems, to avoid external air pressure response, improve performance, and avoid structural differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

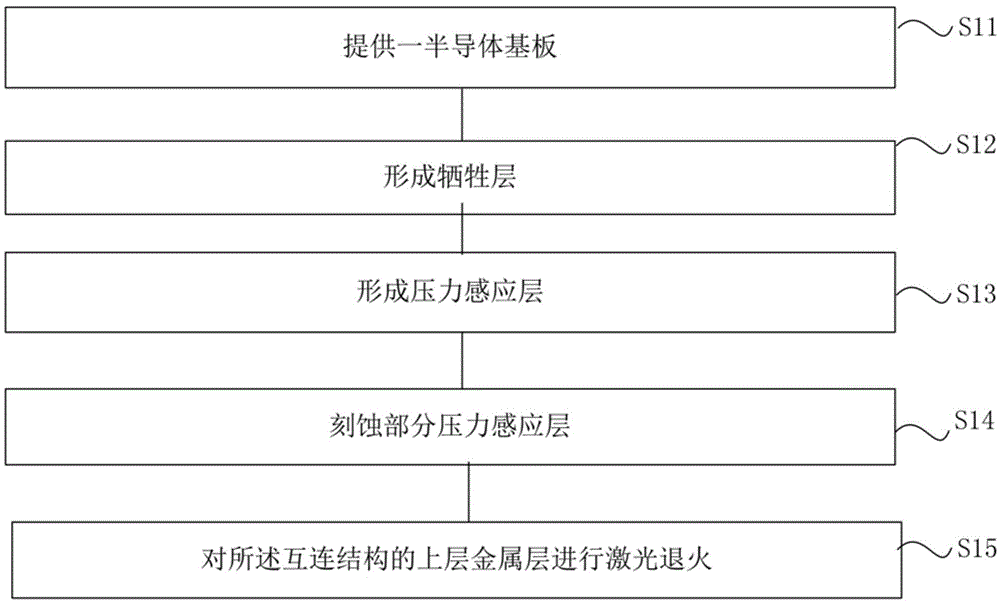

Method used

Image

Examples

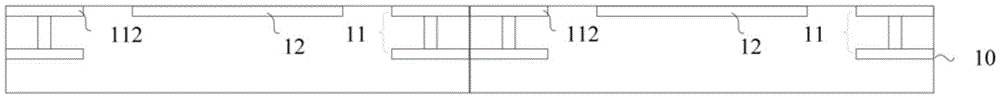

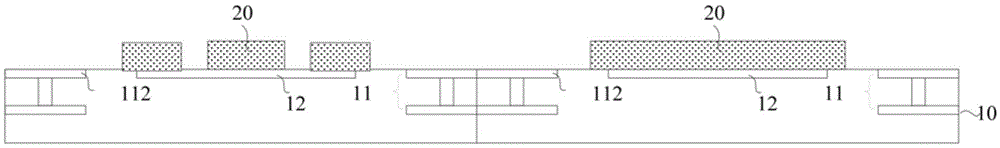

Embodiment Construction

[0030] In the pressure sensor in the prior art, the capacitive pressure sensor is integrated on the CMOS, and the sensor is integrated through the surface process after the CMOS is fabricated. The capacitive pressure sensor is based on the Wheatstone bridge principle and consists of two parts: a reference capacitor and a sensing capacitor. The sensing capacitor has one more window than the reference capacitor to sense the external air pressure. As the air pressure changes, the sensing capacitor realizes the capacitance change through the change of the distance between the upper and lower plates, while the reference capacitor does not change with the air pressure. Finally, the air pressure output is realized by comparing the sensing capacitance with the reference capacitance, and the use of the reference capacitance effectively improves the air pressure measurement accuracy. However, since the sensing window is less than the sensing capacitor, this structural difference affects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com