Method for preparing anatase titanium dioxide

A technology of titanium dioxide and anatase type, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of large particle size and low photocatalytic activity of anatase type titanium dioxide, and achieve high photocatalytic efficiency. Catalytic activity, large surface curvature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

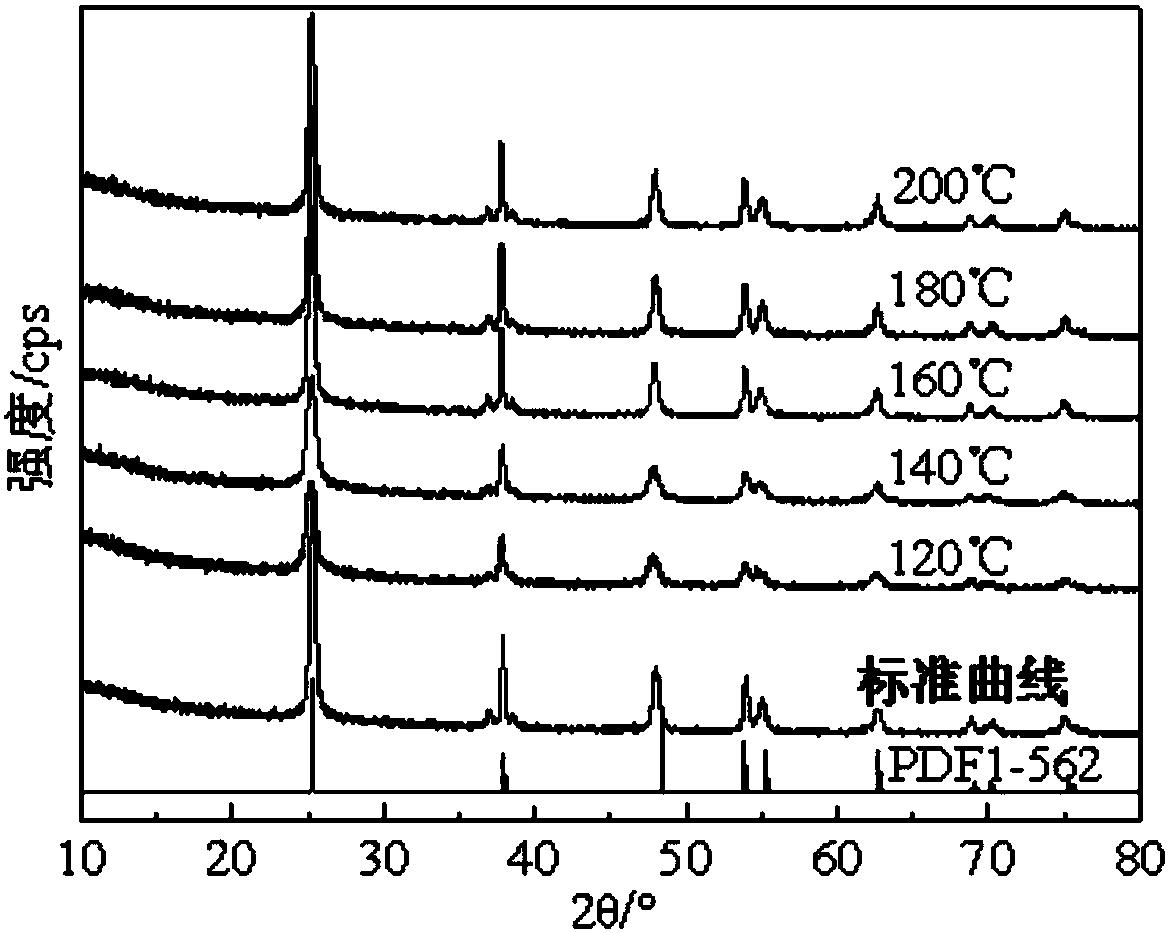

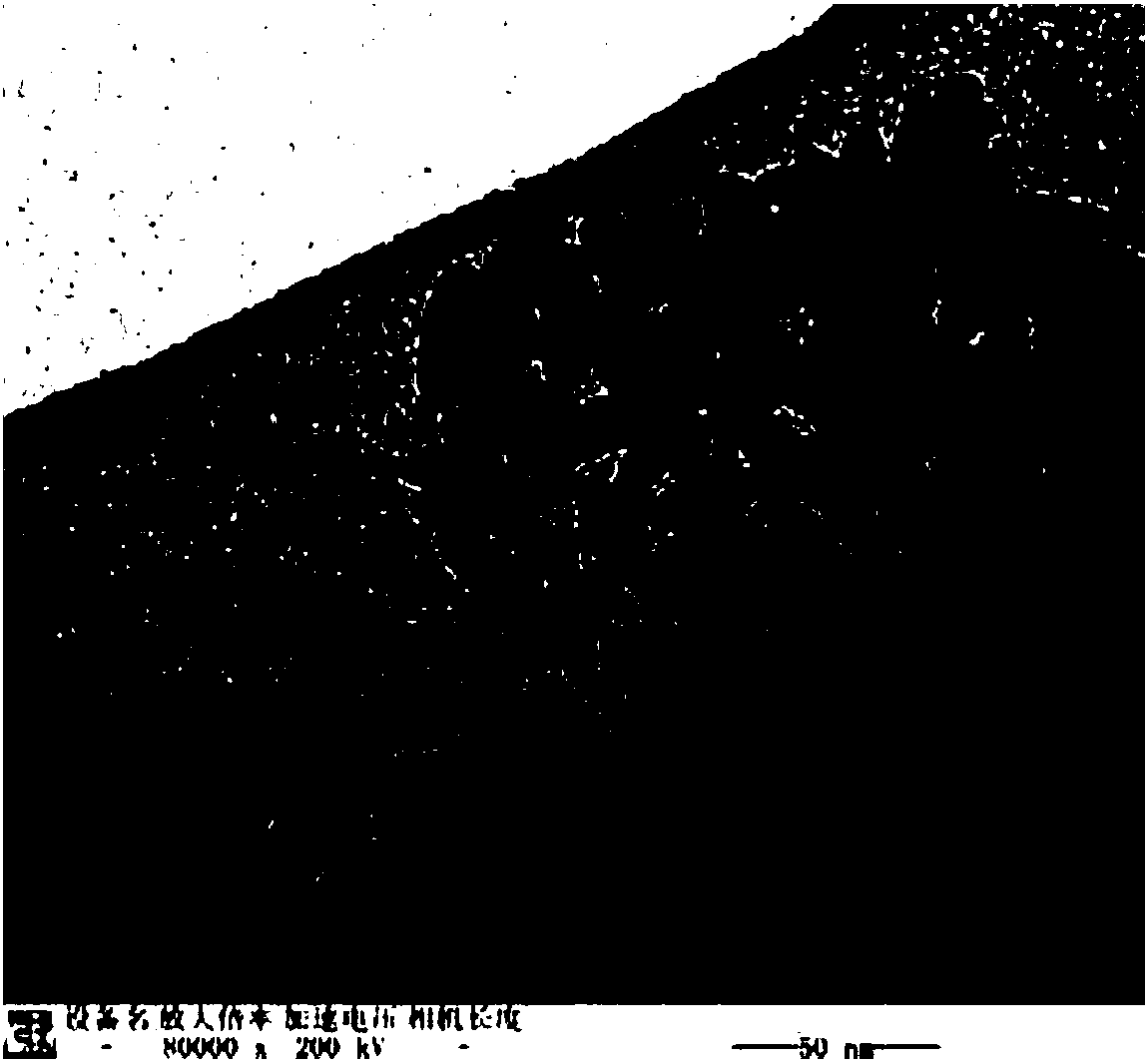

[0026] The preparation method of anatase type titanium dioxide of the present invention comprises the following steps:

[0027] S00. Optionally, titanium tetrachloride is added dropwise to water in an ice-water bath to form a titanium tetrachloride solution.

[0028] That is to say, the titanium tetrachloride solution used in the follow-up can be prepared separately. During the preparation, deionized water can be placed in a beaker, and then the beaker is placed in an ice-water bath to keep warm, and then the tetrachloride solution is added dropwise while stirring. Titanium to form a titanium tetrachloride solution of the desired concentration. Among them, the reason why an ice-water bath is used to keep warm is because titanium tetrachloride and water react violently at room temperature.

[0029] Preferably, the molar concentration of the titanium tetrachloride solution is 0.05-0.2 mol / L.

[0030] It is found through research that the molar concentration of the titanium tet...

Embodiment 1

[0059] This embodiment provides a method for preparing anatase titanium dioxide, which specifically includes the following steps:

[0060] S11. Place the beaker filled with deionized water in an ice-water bath and stir continuously, and add titanium tetrachloride dropwise to prepare a titanium tetrachloride solution with a concentration of 0.1 mol / L.

[0061]S12. Add concentrated ammonia water with a concentration of 12 mol / L to the above solution dropwise, and keep stirring until the solution is neutral and turns into a white suspension.

[0062] S13. Pour the suspension into a suction filtration device for suction filtration, and alternately wash it twice with deionized water and absolute ethanol to finally obtain an amorphous white solid of titanium dioxide.

[0063] S14. Add the above-mentioned amorphous titanium dioxide into 350 ml of deionized water, and stir for 1 hour to form a white suspension. The concentration of the amorphous titanium dioxide in the suspension is 0...

Embodiment 2

[0071] This embodiment provides a method for preparing anatase titanium dioxide, which specifically includes the following steps:

[0072] S21. Place the beaker filled with deionized water in an ice-water bath and stir continuously, and add titanium tetrachloride dropwise to prepare a titanium tetrachloride solution with a concentration of 0.05 mol / L.

[0073] S22. Add concentrated ammonia water with a concentration of 12 mol / L to the above solution dropwise, and keep stirring until the solution is neutral and turns into a white suspension.

[0074] S23. Pour the suspension into a suction filtration device for suction filtration, and alternately wash it twice with deionized water and absolute ethanol to finally obtain an amorphous white solid of titanium dioxide.

[0075] S24. Add the above-mentioned amorphous titanium dioxide into 350 ml of deionized water, and stir for 1 hour to form a white suspension. The concentration of the amorphous titanium dioxide in the suspension is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com