Compound scale and corrosion inhibitor and application thereof in treatment of circulating cooling water

A technology of scale and corrosion inhibitors and compounds, applied in the field of composite scale and corrosion inhibitors and their application in circulating cooling water treatment, to avoid environmental problems, meet the requirements of scale and corrosion inhibition, good scale and corrosion inhibition performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

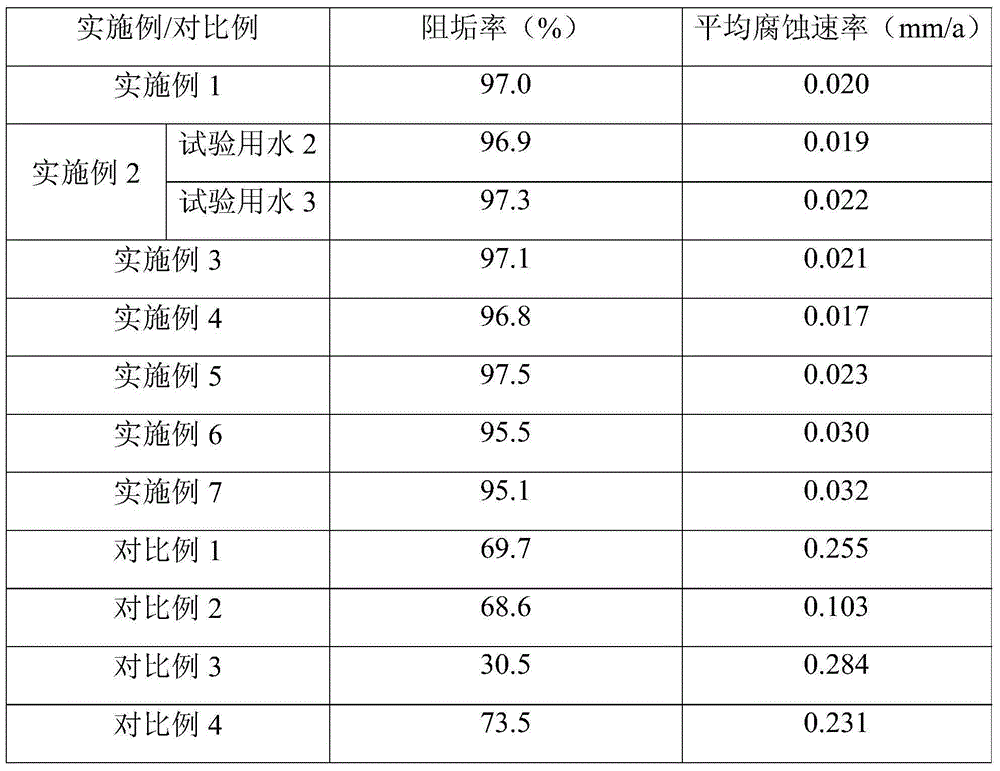

Examples

Embodiment 1

[0043] Weigh 6.0g chitosan (deacetylation degree is 78%), 10.0g carboxymethyl lignin (purchased from Tianjin Huixinde Chemical Product Sales Co., Ltd.) and 18.0g polyepoxysuccinic acid (limited at 30°C) respectively. Viscosity number is 0.078dl / g), was added into 66.0g of water, and shaken well to obtain composite scale and corrosion inhibitor stock solution S1.

[0044] Take 1g of the prepared composite scale and corrosion inhibitor stock solution S1 and add it to 10L of test water 1, so that the effective concentrations of chitosan (deacetylation degree is 78%), carboxymethyl lignin and polyepoxysuccinic acid in the water are respectively 6mg / L, 10mg / L and 9mg / L, and then carry out the calcium carbonate scale inhibition performance test and corrosion inhibition performance test according to the method in the test example.

Embodiment 2

[0046] Weigh 3.14g of zinc chloride, dissolve it in 9.0g of polyaspartic acid (at 30°C, the limiting viscosity number is 0.074dl / g), then add 3.0g of carboxymethyl chitosan and 18.0g of carboxymethyl cellulose (purchased from Jinye Industrial Co., Ltd., Renqiu, Hebei), and then add 46.86g of water, and shake well to obtain the composite scale and corrosion inhibitor stock solution S2.

[0047] Take 0.8g of the prepared composite scale and corrosion inhibitor stock solution S2 and add it to 10L of test water 2 or 10L of test water 3, so that carboxymethyl chitosan, carboxymethyl cellulose, polyaspartic acid and zinc ions in the water The effective concentrations are 3mg / L, 18mg / L, 4.5mg / L and 1.5mg / L respectively, and then the calcium carbonate scale inhibition performance is determined according to the method in the test example.

[0048] Use sulfuric acid to adjust the pH value of the test water 2 to 7.8-8.3, then add the compound scale and corrosion inhibitor stock solution ...

Embodiment 3

[0050] 0.16g hydroxyethyl chitosan, 60.0mg sodium lignosulfonate (purchased from Jinan Liangfeng Trading Co., Ltd.), 0.12g polyaspartic acid (limiting viscosity at 30°C is 0.079dl / g) and 10.0mg of benzotriazole were added into 10L of test water 1, so that the effective concentrations of hydroxyethyl chitosan, sodium lignosulfonate, polyaspartic acid and benzotriazole in the water were 16mg / L, respectively. 6mg / L, 6mg / L and 1mg / L, and then measure the calcium carbonate scale inhibition performance and corrosion inhibition performance according to the method in the test example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com