Salt-production scale inhibitor and application thereof

A scale inhibitor and one-element technology, applied in the field of scale inhibitor and dispersant, can solve the problems of reducing sulfate content, obvious scale inhibition effect of single precipitation, inconvenient operation, etc., and achieves enhanced chlorine resistance, good synergistic effect, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

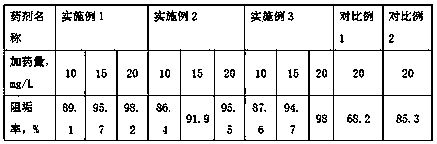

Examples

Embodiment 1

[0018] Salt-making antiscaling agent, the mass percentages of effective components of each substance are: 5% of 1,6-hexamethylenetriaminepentamethylenephosphonic acid, 8% of diethylenetriaminepentamethylenephosphonic acid heptasodium salt, carboxylic acid Salt-sulfonate-nonionic terpolymer 2%, phosphonocarboxylic acid copolymer 2%, sodium polyacrylate 12%, caustic soda 2.8%, deionized water 68.2%.

[0019] Among them, the carboxylate-sulfonate-nonionic terpolymer is composed of monomer acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid and hydroxypropyl acrylate in a mass ratio of 12.5:6:1 at 90 It is prepared by polymerization at ℃, and the viscosity-average molecular weight is 4300.

[0020] The antiscalant was applied to a salt field in Huainan, and the system could continue to operate for more than 10 months when used at a concentration of 20mg / L, and the antiscalant effect was obvious.

Embodiment 2

[0022] Salt-making antiscaling agent, the mass percentages of effective components of each substance are: 7% of 1,6-hexamethylenetriaminepentamethylenephosphonic acid, 5% of heptasodium diethylenetriaminepentamethylenephosphonic acid, 5% of ethylene diaminepentamethylenephosphonic acid Sodium amine tetramethylene phosphonate 7%, phosphonocarboxylic acid copolymer 5%, hydrolyzed polymaleic anhydride 5%, caustic soda 6%, deionized water 65%.

[0023] The antiscalant was applied to a salt field in Henan, and the system could continue to operate for more than 10 months when used at a concentration of 20mg / L, and the antiscalant effect was obvious.

Embodiment 3

[0025] Salt-making antiscaling agent, the mass percentages of effective components of each substance are: 7% of 1,6-hexamethylenetriaminepentamethylenephosphonic acid, 4% of diethylenetriaminepentamethylenephosphonic acid, butyl 2-phosphonate Alkane-1,2,4-tricarboxylic acid 4%, carboxylate-sulfonate-nonionic terpolymer 5%, phosphonocarboxylic acid copolymer 4%, hydrolyzed polymaleic anhydride 3%, polyacrylic acid 4%, deionized water 69%.

[0026] Among them, carboxylate-sulfonate-nonionic terpolymer is composed of monomer acrylic acid, 2-acrylamide-2-methylpropanesulfonic acid and hydroxypropyl acrylate in a mass ratio of 12.5:6:1 at 95 It is prepared by polymerization at ℃, and the viscosity-average molecular weight is 3800.

[0027] The antiscalant was applied to a salt field in Ningxia, and the system could continue to operate for more than 10 months when used at a concentration of 20mg / L, and the antiscalant effect was obvious.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com