High efficiency scale and corrosion inhibitor for treating industrial circulating cooling water

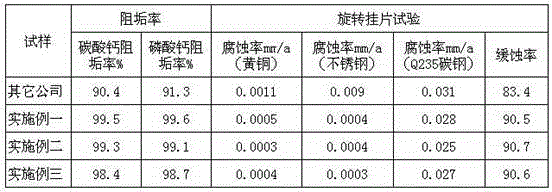

A technology of circulating cooling water and scale and corrosion inhibitor, applied in the field of scale and corrosion inhibitor, can solve the problems of high corrosion rate of stainless steel, affecting service life, low scale inhibition rate, etc., achieving good corrosion inhibition performance, preventing scale, good preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A high-efficiency scale and corrosion inhibitor for treating industrial circulating cooling water, comprising the following raw materials in proportions by weight: 9 parts of 2-phosphonic acid butane-1,2,4-tricarboxylic acid, polyamino polyether 9 parts of methylene phosphonic acid, 10 parts of hydroxyethylidene diphosphonic acid, 10 parts of diethylene triamine pentamethylene phosphonic acid, 6-8 parts of 2-hydroxyphosphonoacetic acid, acrylic acid-hydroxypropyl acrylate-AMPS 7 parts of terpolymer, 7 parts of hydrolyzed polymaleic anhydride, 11 parts of zinc sulfate heptahydrate and 1 part of tolyl benzotriazole, polyamino polyether group methylene phosphonic acid is very good in circulating cooling water Excellent calcium tolerance, strong anti-scaling ability to calcium carbonate and calcium sulfate, and can well stabilize iron, zinc, manganese sulfide, also very effective for silicon and silicate, acrylic acid-hydroxypropyl acrylate The copolymer has a good inhibito...

Embodiment 2

[0018] A high-efficiency scale and corrosion inhibitor for treating industrial circulating cooling water, comprising the following raw materials in proportions by weight: 10 parts of 2-phosphonic acid butane-1,2,4-tricarboxylic acid, polyamino polyether 10 parts of methylene phosphonic acid, 10 parts of hydroxyethylidene diphosphonic acid, 10 parts of diethylene triamine pentamethylene phosphonic acid, 8 parts of 2-hydroxyphosphonoacetic acid, acrylic acid-hydroxypropyl acrylate-AMPS ternary 8 parts of copolymer, 8 parts of hydrolyzed polymaleic anhydride, 12 parts of zinc sulfate heptahydrate and 2 parts of methyl benzotriazole, polyamino polyether group methylene phosphonic acid has good calcium content in circulating cooling water Tolerance, has strong scale inhibition ability to calcium carbonate and calcium sulfate, and can well stabilize iron, zinc, manganese sulfide, and is also very effective for silicon and silicate, acrylic acid-hydroxypropyl acrylate copolymer It ha...

Embodiment 3

[0021] A high-efficiency scale and corrosion inhibitor for treating industrial circulating cooling water, comprising the following raw materials in proportions by weight: 8 parts of 2-phosphonic acid butane-1,2,4-tricarboxylic acid, polyamino polyether 8 parts of methylene phosphonic acid, 8 parts of hydroxyethylidene diphosphonic acid, 8 parts of diethylenetriaminepentamethylene phosphonic acid, 6 parts of 2-hydroxyphosphonoacetic acid, acrylic acid-hydroxypropyl acrylate-AMPS ternary 6 parts of copolymer, 6 parts of hydrolyzed polymaleic anhydride, 10 parts of zinc sulfate heptahydrate and 1 part of methyl benzotriazole, polyamino polyether group methylene phosphonic acid has good calcium content in circulating cooling water Tolerance, strong anti-scale ability to calcium carbonate and calcium sulfate, and can stabilize iron, zinc, manganese sulfide, also very effective to silicon and silicate, acrylic acid-hydroxypropyl acrylate copolymer It has a good inhibitory effect on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com