Sewage treatment process for dyeing and weaving

A sewage treatment and sewage technology, which is applied in water/sewage treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc. It can solve the problems of difficult degradation of dyes, deep chroma, and complex composition of dyeing wastewater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

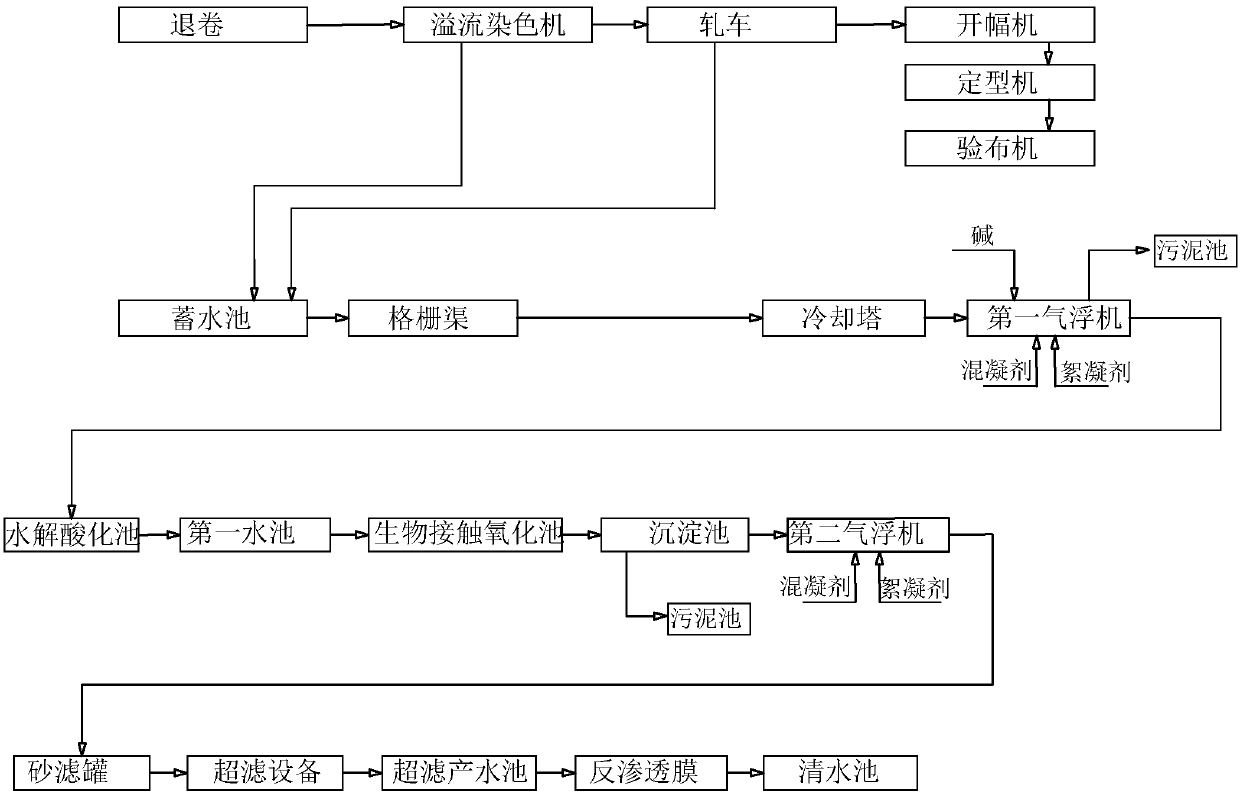

[0049] Reference Figure 1 to Figure 7 The present invention will be further explained.

[0050] In the textile industry, the fabric roll is unrolled, and then the fabric is dyed in an overflow dyeing machine, and the dyed fabric is dehydrated by a paddle and then placed in a slitting machine for flattening; then the fabric is placed in a setting machine for processing It is shaped at high temperature and then inspected by a cloth inspecting machine before rewinding, which completes the dyeing process of the fabric.

[0051] But in the process of dyeing and dehydration, a lot of sewage will be produced. This requires sewage treatment.

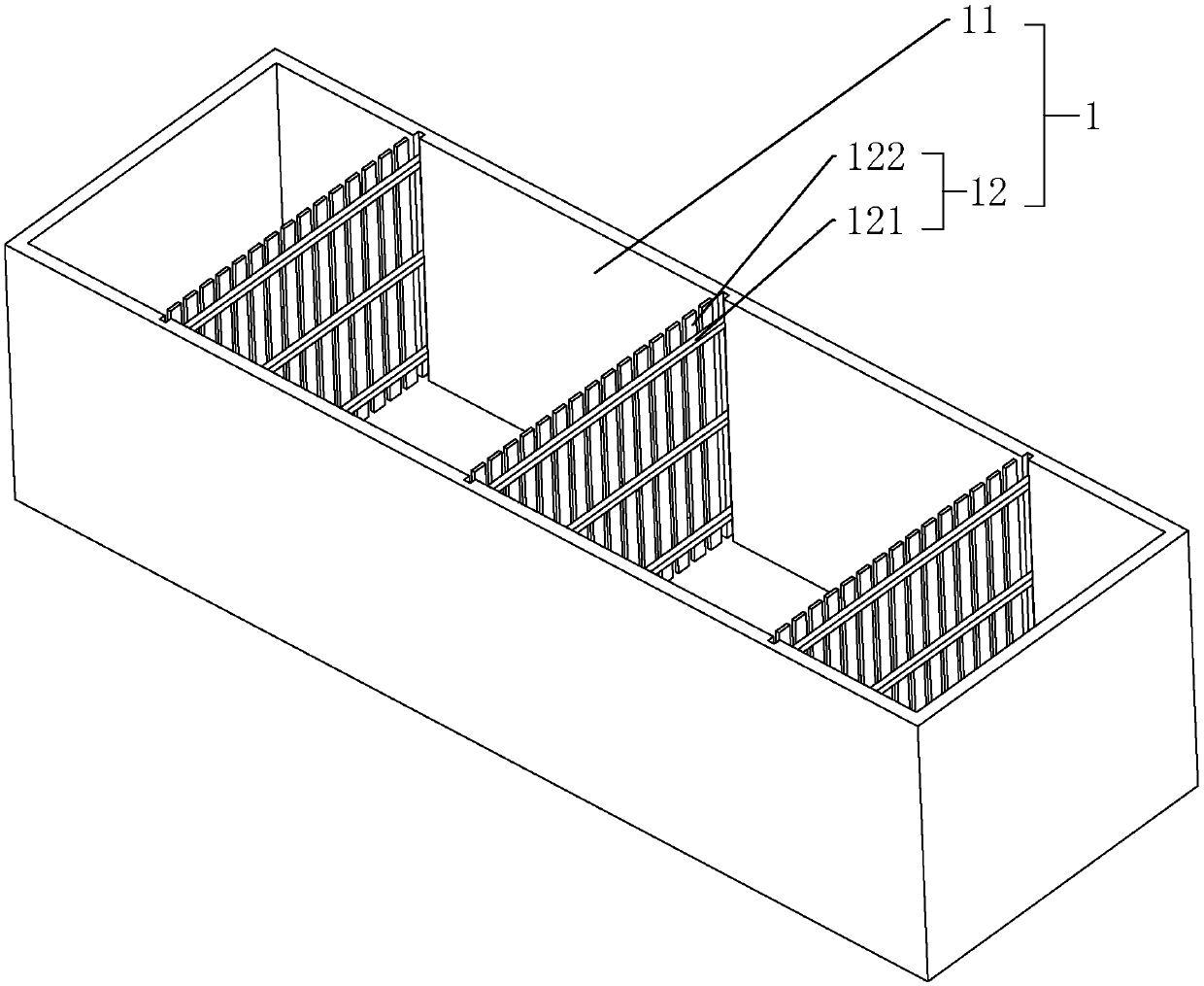

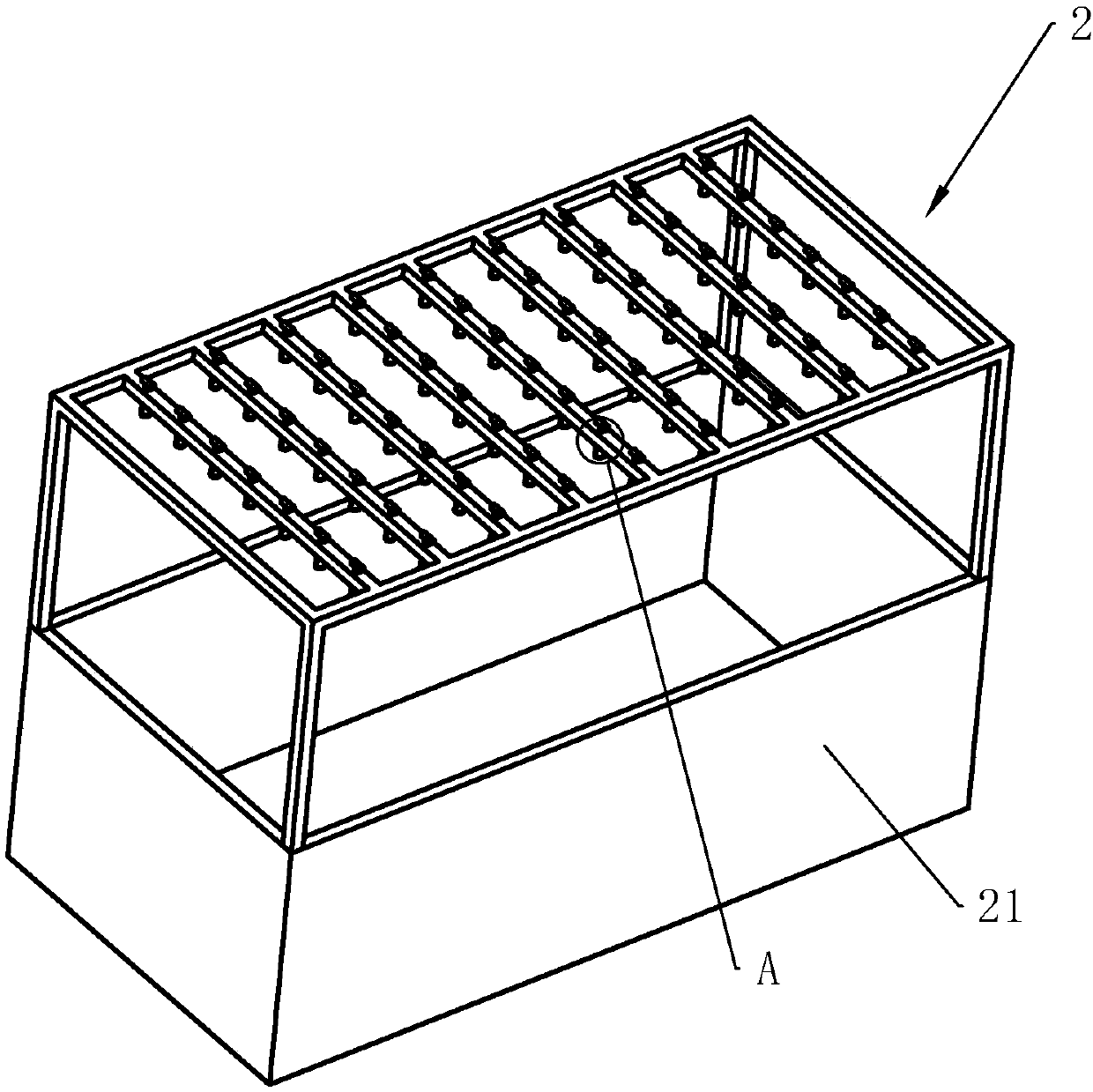

[0052] Such as figure 1 with figure 2 As shown, a wastewater treatment process for dyeing and weaving includes a reservoir, and the above-mentioned wastewater is introduced into the reservoir through a first water pipe for storage. A water outlet is opened on the side wall of the reservoir. The grid channel 1 is placed on the side wall of the rese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com