Citric acid-ascorbic acid hydrogen calcium zinc and preparation method and application thereof

A technology of calcium hydrogen acid zinc, ascorbic acid, applied in the field of biochemical medicine and food, can solve the problems such as can not be made into eye drops, oral liquid and injection, no citric acid report, can not provide zinc, etc., achieve easy operation, reaction The effect of fast time and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

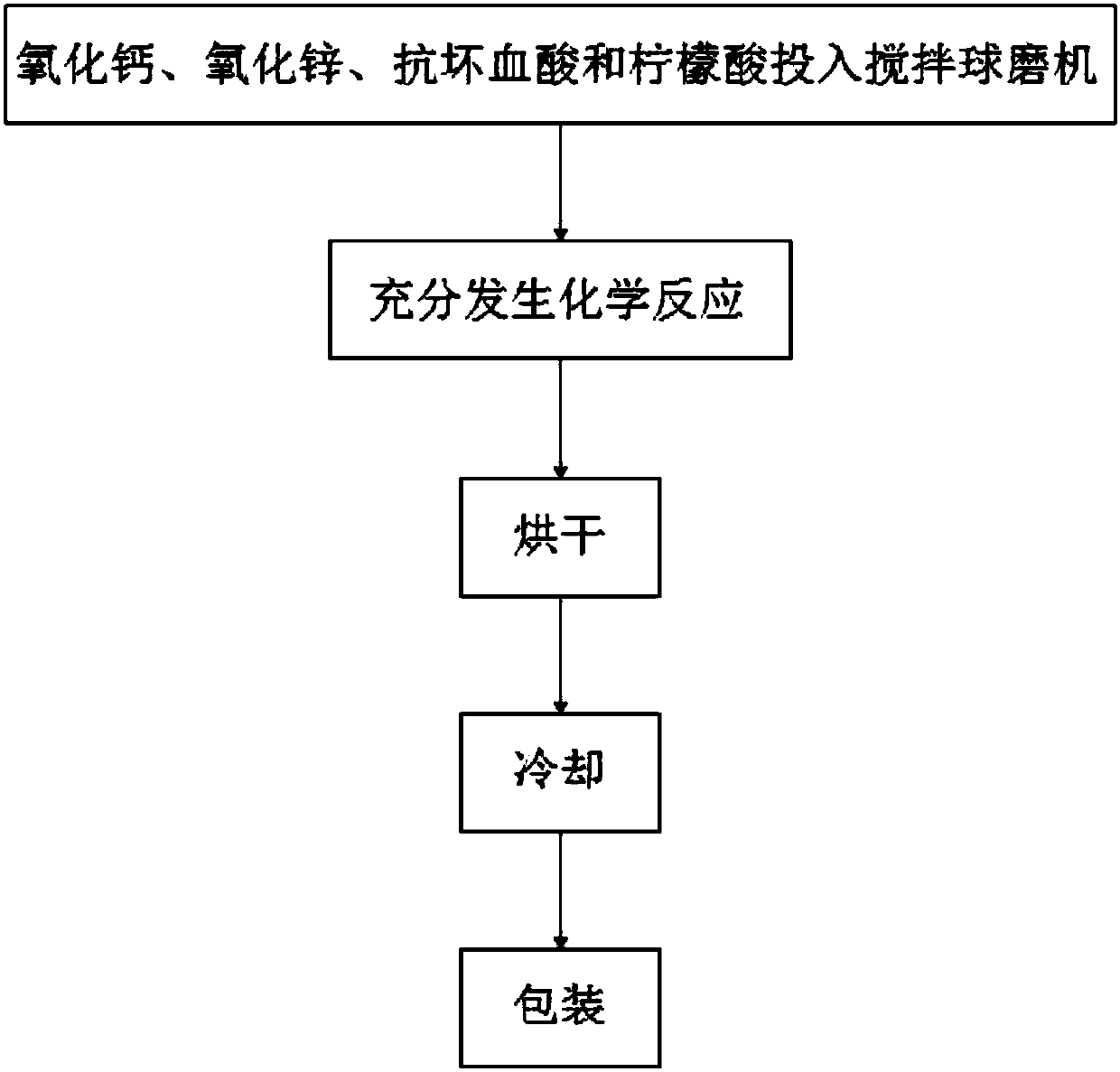

[0028] The preparation method of the present embodiment calcium ascorbate zinc hydrogen citric acid comprises the following steps:

[0029] (1) Take raw material calcium oxide powder 1120.0g, zinc oxide powder 81.4g, ascorbic acid powder 3874.6g and citric acid powder 1345.0g, raw material is dropped in the stirring ball mill, start stirring ball mill, carry out chemical reaction under normal temperature, chemical reaction formula is :

[0030] 20CaO+ZnO+22C 6 h 8 o 6 +7C 6 h 8 o 7 = Ca 20 ZnH(C 6 h 7 o 6 ) 22 (C 6 h 5 o 7 ) 7 21H 2 O.

[0031] (2) After fully reacting for 40 minutes, stop stirring the ball mill and release the product, and dry the product at a temperature of 105°C;

[0032] (3) The product after drying was cooled to room temperature, and weighed after cooling to obtain 6292.6 g of calcium zinc hydrogen ascorbate citrate.

[0033] (4) packing the finished product of calcium ascorbate zinc hydrogen citric acid gained in step (3).

Embodiment 2

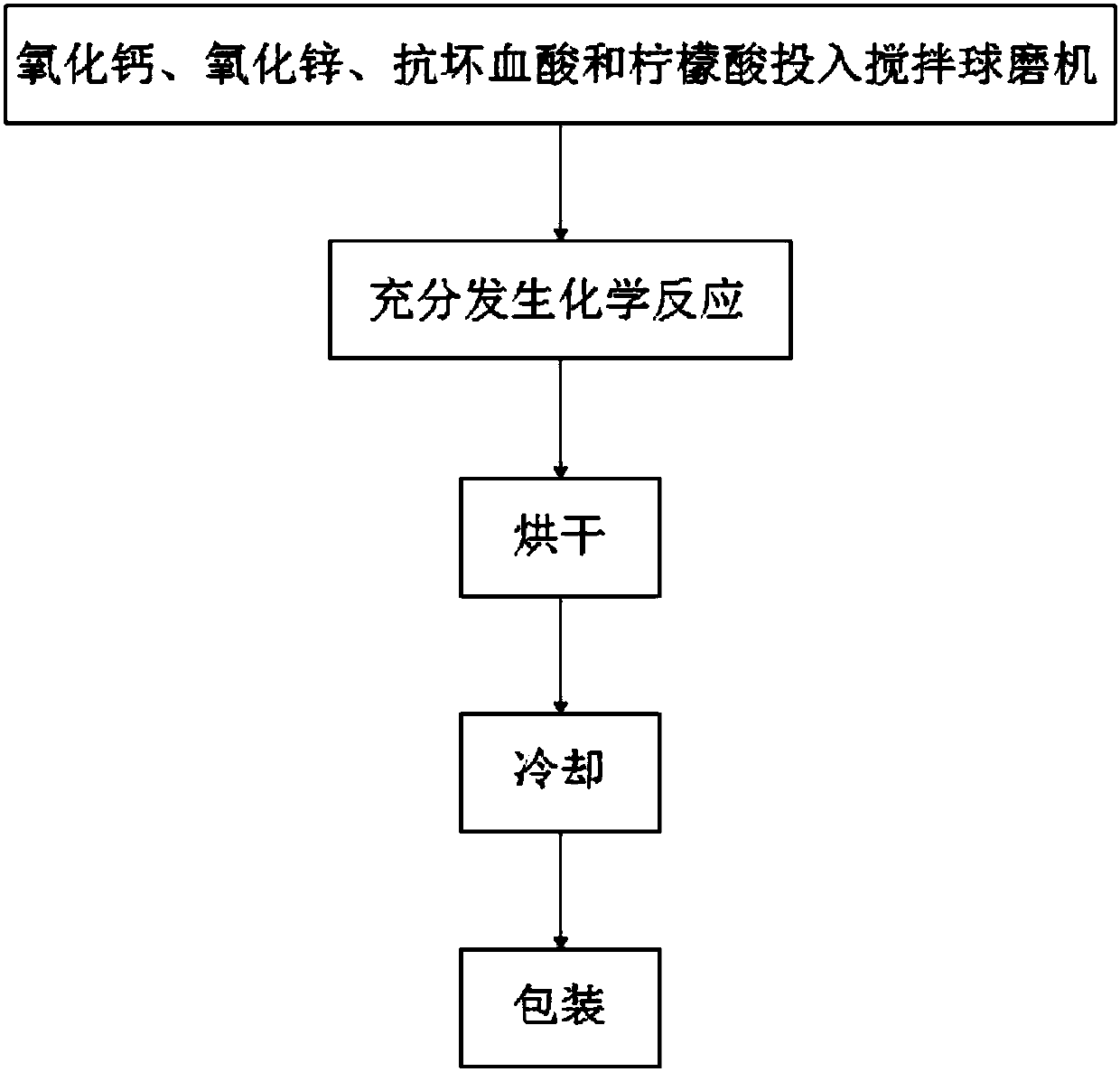

[0035] The preparation method of the present embodiment calcium ascorbate zinc hydrogen citric acid comprises the following steps:

[0036] (1) Weigh 560.0g of raw material calcium oxide powder, 40.7g of zinc oxide powder, 1937.3g of ascorbic acid powder and 672.5g of citric acid powder, put the raw materials into the stirring ball mill, start the stirring ball mill, and carry out the chemical reaction under normal temperature, the chemical reaction formula is :

[0037] 20CaO+ZnO+22C 6 h 8 o 6 +7C 6 h 8 o 7 = Ca 20 ZnH(C 6 h 7 o 6 ) 22 (C 6 h 5 o 7 ) 7 21H 2O.

[0038] (2) After fully reacting for 30 minutes, stop stirring the ball mill and release the product, and dry the product at a temperature of 102°C;

[0039] (3) The dried product was cooled to room temperature, and weighed after cooling to obtain 3178.4 g of the product calcium zinc hydrogen ascorbate citric acid.

[0040] (4) packing the finished product of calcium ascorbate zinc hydrogen citric aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com