Underwater explosion shock wave equivalent loading experimental device

A technology of loading experiment and underwater explosion, which is applied in the direction of measuring device, impact test, machine/structural component test, etc., can solve the problems of high experimental environment requirements, high risk factor, poor controllability, etc., and achieve strong operability , high safety and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below with examples in conjunction with the accompanying drawings.

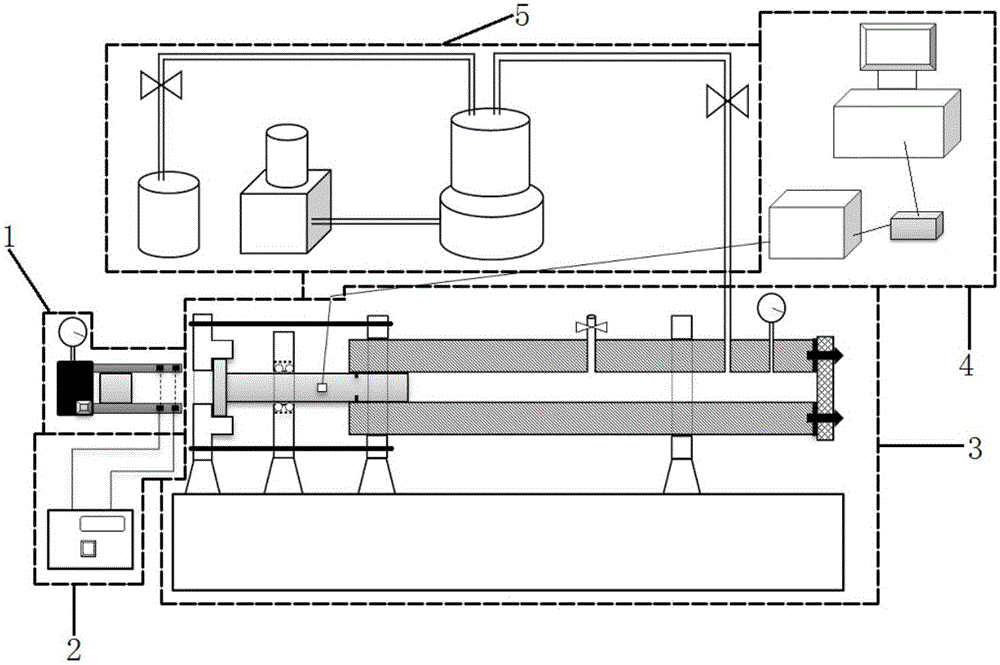

[0026] combine figure 1 , The experimental device of the present invention includes five main parts of a launching system 1, a speed measuring system 2, a high pressure water tank system 3, a measuring system 4 and a hydraulic system 5. This test method uses the knowledge of reflection and transmission of elastic waves in shock dynamics to indirectly obtain equivalent underwater explosion shock waves by measuring the incident waves and reflected waves on the incident rod in the experimental device.

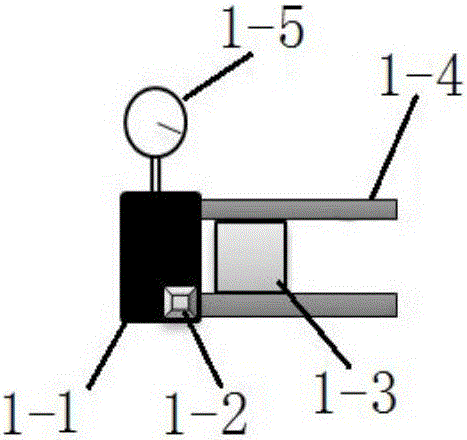

[0027] combine figure 2 , the launch system includes high-pressure gas chamber 1-1, gas chamber pressure gauge 1-5, launch tube 1-4, bullet 1-3, trigger device 1-2 and other components, the gas chamber pressure gauge is installed on the wall of the high-pressure gas chamber, It communicates with the air chamber, and the launch tube is closely connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com