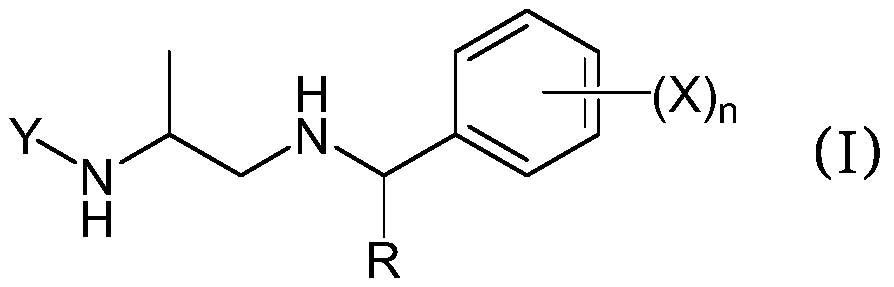

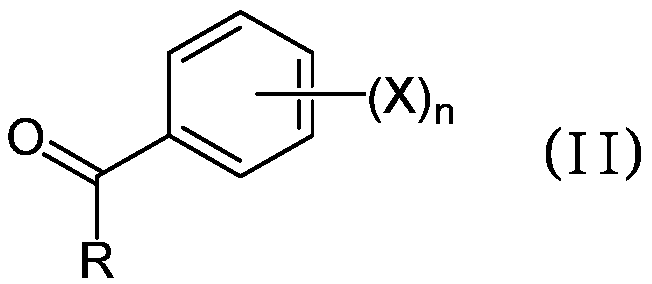

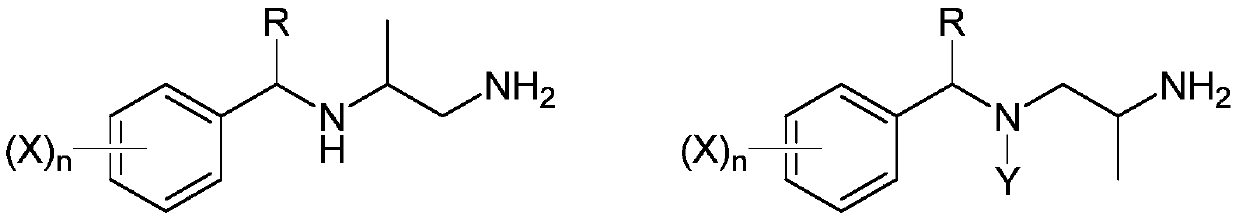

Amines for Low Emission Epoxy Compositions

A technology of epoxy resin and composition, applied in the field of paint, cladding or brushing material, which can solve the problem of strong odor and whitening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0180] Examples are described below, which explain the present invention in more detail. The invention is of course not limited to the described embodiments.

[0181] "AHEW" means amine hydrogen equivalent weight.

[0182] "EEW" means epoxide equivalent weight.

[0183] "Standard climate" means a temperature of 23±1° C. and a relative air humidity of 50±5%. "NK" stands for "Normal Climate".

[0184] Description of measurement method:

[0185] Infrared spectra (FT-IR) were measured in the form of undiluted films on Perkin-Elmer's FT-IR apparatus 1600 equipped with a horizontal ATR-measuring unit with ZnSe-crystals; absorption bands are expressed in wavenumbers (cm -1 ) means (measurement window: 4000-650cm -1 ).

[0186] 1 H-NMR-spectra were measured on a Bruker Ascend 400 spectrometer at 400.14 MHz; chemical shifts δ are expressed in ppm relative to tetramethylsilane (TMS). No distinction is made between true and pseudo-coupling styles.

[0187] Gas chromatography (G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com